Method for preparing composite membrane through interfacial polymerization and reaction device

A technology of interfacial polymerization and reaction device, which is applied in chemical instruments and methods, chemical/physical/physical-chemical fixed reactors, membranes, etc., and can solve problems such as difficulty in achieving equipment and reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

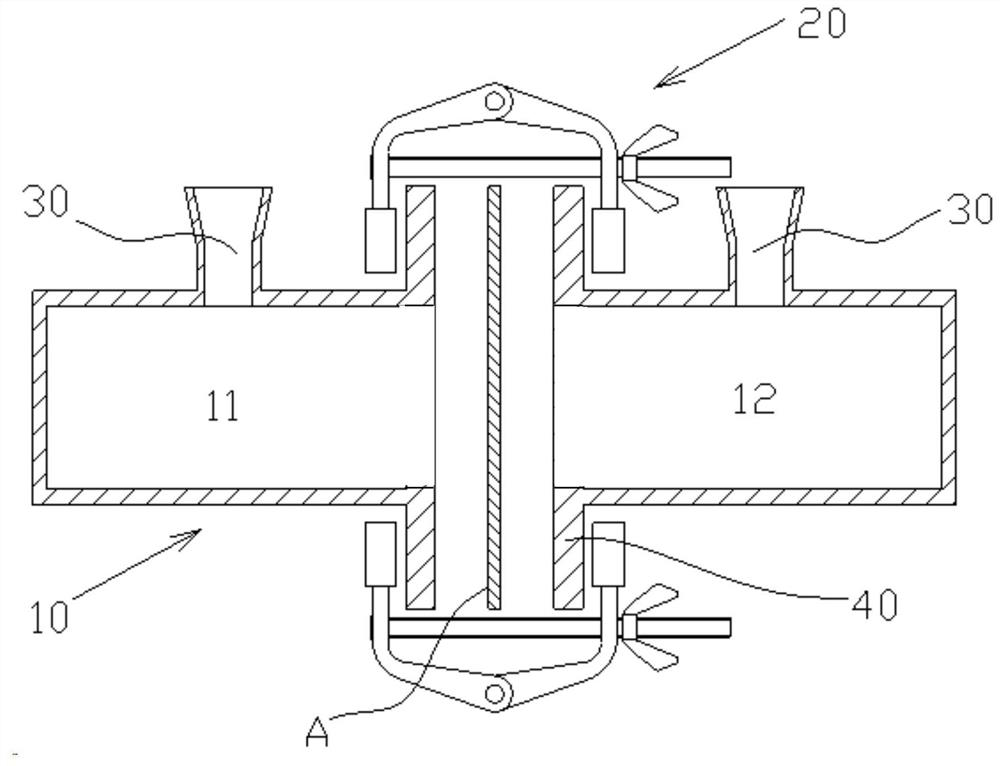

Image

Examples

Embodiment 1

[0025] Interfacial polymerization of the present invention is a composite membrane reactor, the support A polyacrylonitrile ultrafiltration membrane, the support member A was cut into two identical half-vitro cuff size and shape of the reaction apparatus, the reaction apparatus is assembled for use.

[0026] Prepared solution: aqueous phase concentration para-phenylenediamine 0.0225mol / L, L aqueous solution of p-toluenesulfonic acid concentration 0.0675mol / , the organic phase is between three phloroglucinol aldehyde concentration 0.0075mol / L in n-hexane.

[0027] After the biphasic solution were added simultaneously as possible on both sides of the cavity to the supporting body A, and on both sides of the liquid level height remains the same, gradually forming a polymer film on one side of a support an organic phase solution A, and reacted for 24 hours to complete the reaction, while the solution was poured out of the sides, removing the support a is the composite membrane pr...

Embodiment 2

[0029] Using the same method as in Example 1 composite membrane, wherein a concentration of the aqueous phase is benzidine 0.05mol / L, an aqueous solution of L-toluenesulfonic acid concentration of 0.15mol / , the organic phase was pyrogallol among the three aldehyde concentration was 0.016mol / L in n-hexane, the reaction time was 6 hours, the resulting polymer composite film layer having a thickness of 50nm.

[0030] Using the same method as in Example 1. The resulting composite membrane is detected, the detection results recorded in Table 1.

Embodiment 3

[0032] Composite membrane prepared using the same method as in Example 1, the aqueous phase is benzidine concentration of 0.04mol / L, p-toluenesulfonic acid at a concentration of 0.12mol L aqueous / organic phase is among the three phloroglucinol aldehyde concentration was 0.011mol / L in n-hexane, the reaction time was 4 hours, the resulting polymer composite film layer having a thickness of 30nm.

[0033] Using the same method as in Example 1. The resulting composite membrane is detected, the detection results recorded in Table 1.

[0034] Table 1 Example 1-3 Detection results of the composite film obtained

[0035] Permeability coefficient (L / M 2 · H · bar)

[0036] It can be seen from Table 1 that the COFS composite film prepared by the solution of the present invention is greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com