Manufacturing method of high-performance 42CrMo gear

A production method and high-performance technology, applied in the direction of wheels, manufacturing tools, forging/pressing/hammering machinery, etc., to achieve the effect of compact structure, good wear resistance and high tempering resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method of manufacturing a high-performance 42CrMo gear, comprising the following steps:

[0043] (1) Determine the technological process to be adopted;

[0044] (2) Die forging process planning and numerical simulation;

[0045] (3) Optimize the die forging process according to the numerical simulation results, determine the final die forging plan, and start the mold making;

[0046] (4) Re-examination of raw materials to check whether the chemical components meet the technical specifications;

[0047] (5) Determine the specification and size of the blank according to the forging process, and cut the material;

[0048] (6) Blank heating: According to the heating process, the blank is heated, and the mold is preheated at the same time;

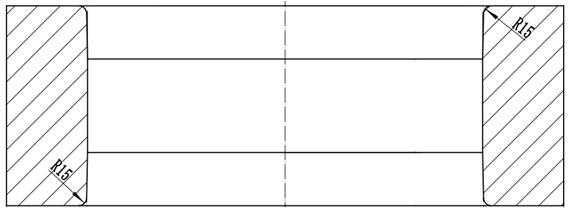

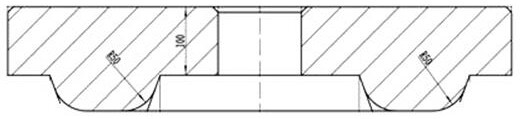

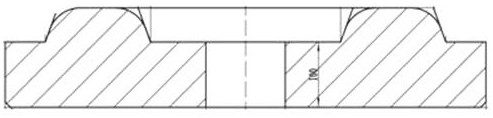

[0049] (7) Die forging: According to the planned die forging process, the tire die forging of the gear is carried out; the die forging process includes the following steps: figure 1 , attached figure 2 and attached image 3 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com