Recyclable packaging material

A technology for packaging materials and sheet materials, applied in the field of recyclable packaging materials, can solve the problems of pulp pollution, low recycling efficiency, limited performance, etc., and achieve a simplified recycling process, high quality of returned materials, and low performance attenuation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

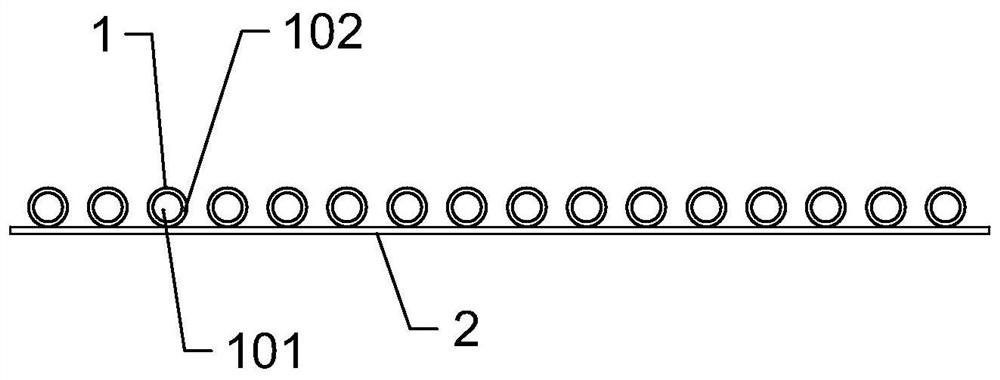

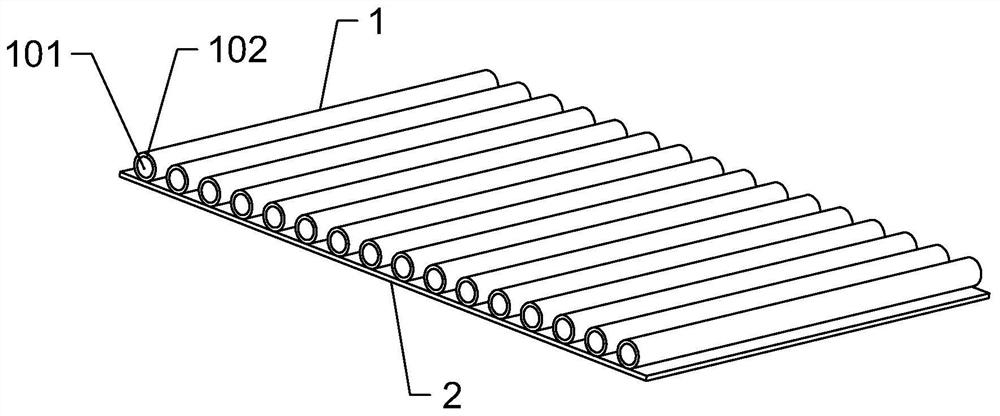

[0037] A recyclable packaging material such as Figure 1-2 As shown, it includes a buffer support unit 1 and an inner functional film 2, and the buffer support unit 1 and the inner functional film 2 are made of polyethylene. The buffer support unit 1 is a hollow structure with a through hole 101 in the middle, and the cross-sectional shape of the through hole 101 is circular. The through holes 101 are distributed along the length direction of the support unit 1. The through holes 101 are integrally formed after the buffer support unit 1 is extruded by a hot pressing process. A cavity 102 is provided between the through holes 101 and the outer wall of the buffer support unit 1. The cavity 102 is filled with air.

[0038] The width of the inner functional film 2 is 5-20 cm wider than the length of the buffer support unit 1. There are several buffer support units 1 with the same specifications. Several buffer support units 1 are uniformly and centrally distributed on the inner f...

specific Embodiment 2

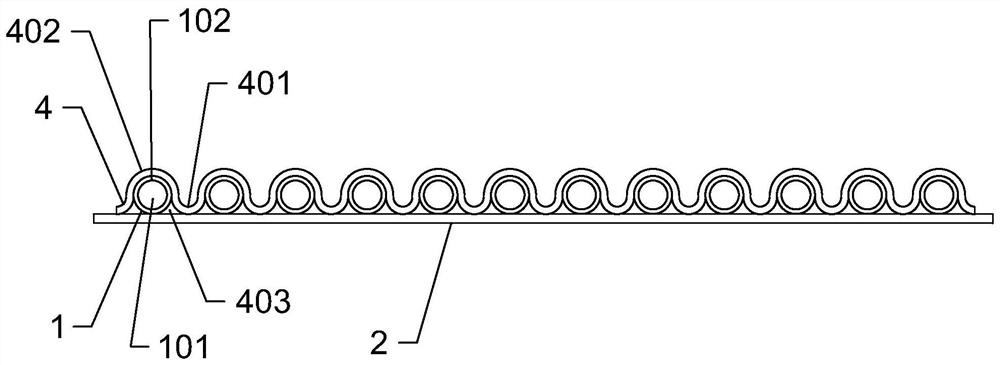

[0045] A recyclable packaging material such as Figure 3-4As shown, on the basis of Embodiment 1, a middle-layer functional film 4 is added, and the middle-layer functional film 4 is made of polyethylene. The middle functional film 4 is distributed on the inner functional film 2 in an S-shape, and the middle functional film 4 includes a plurality of lower arc-shaped bending parts 401 and upper arc-shaped bending parts 402 arranged sequentially first, and the lower arc-shaped bending part 401 The outer surface of the inner layer functional film 2 is fixed on the upper surface of the inner layer functional film 2 by hot pressing, and the edge positions of the inner layer functional film 2 and the middle layer functional film 4 along the length direction are hot pressing sealed, so that the middle layer functional film 4 and the inner layer functional film 2 A closed first arc-shaped groove 403 is formed between them, and several cushioning and supporting units 1 are sequentially...

specific Embodiment 3

[0050] A recyclable packaging material such as Figure 5-6 As shown, on the basis of Embodiment 1, a middle-layer functional film 4 is added, and the middle-layer functional film 4 is made of polyethylene. The middle functional film 4 is distributed on the inner functional film 2 in an S-shape, and the inner functional film 4 includes a plurality of lower arc-shaped bending parts 401 and upper arc-shaped bending parts 402 arranged sequentially first, and the lower arc-shaped bending parts The outer surface of 401 is heat-pressed and fixed on the upper surface of the inner functional film 2, and the edges of the inner functional film 2 and the middle functional film 4 along the length direction are sealed by heat and pressure, so that the middle functional film 4 and the inner functional film A closed first arc-shaped groove 403 and an open second arc-shaped groove 404 are formed between the 2, and several buffer support units 1 are sequentially fixed on the first arc-shaped gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com