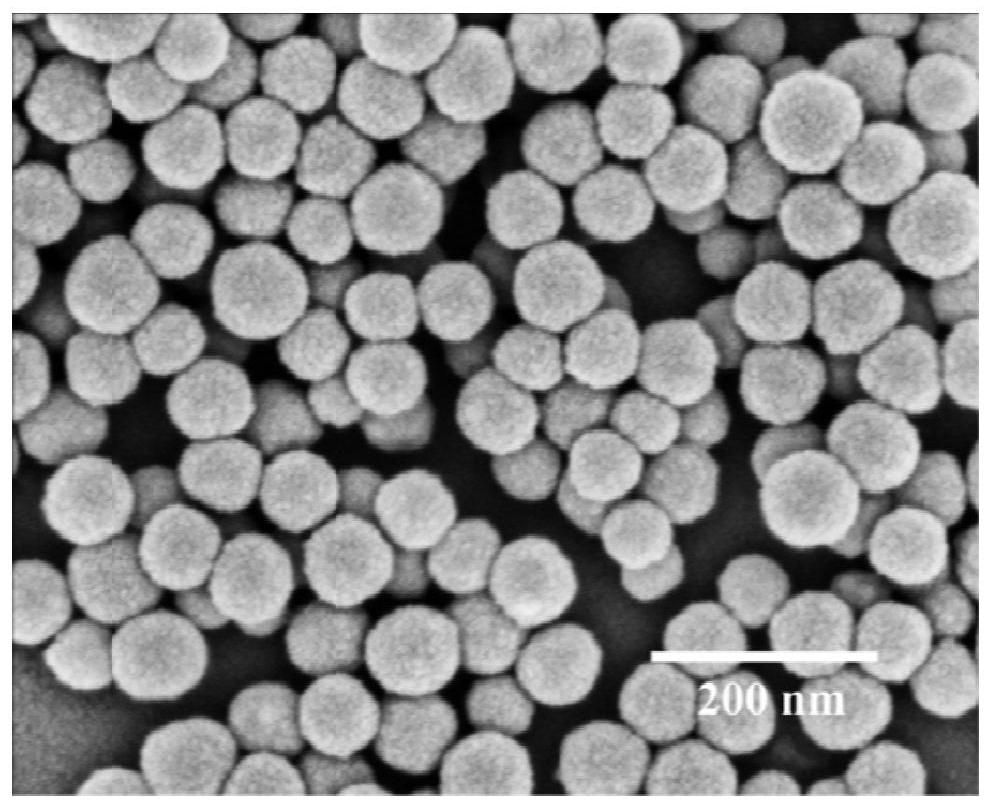

Method for preparing carbon nanospheres through cooperation of pressure and dispersing agent

A technology of nano carbon balls and dispersants, which is applied in nano carbon, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of easy adhesion, difficulty in making carbon balls small, low yield, etc. Yield, size uniformity, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A high-efficiency preparation method of hydrothermal nano-carbon spheres, comprising the following steps:

[0031] S1, configure the concentration of glucose solution to be 1.0M, the amount of dispersant poly(4-styrenesulfonic acid-co-maleic acid) sodium salt (PSSMA) is 1% of the amount of glucose, and stir to obtain a mixed solution;

[0032] S2. Take 33mL of the mixed solution configured in step S1 and put it into a 100mL autoclave. After the autoclave is sealed, nitrogen gas is introduced through the air inlet so that the initial pressure in the still is 4.0MPa;

[0033] S3. Heating the autoclave in step S2 to 200° C. and then keeping the temperature for 3 hours. After the reaction, naturally cool to room temperature to obtain a carbon nanosphere solution;

[0034] S4. Separate the nano-carbon sphere solution obtained in S3 at a centrifugal rate of 18000r / min for 30 minutes, centrifuge with deionized water, and ultrasonically disperse and wash three times, and then u...

Embodiment 2

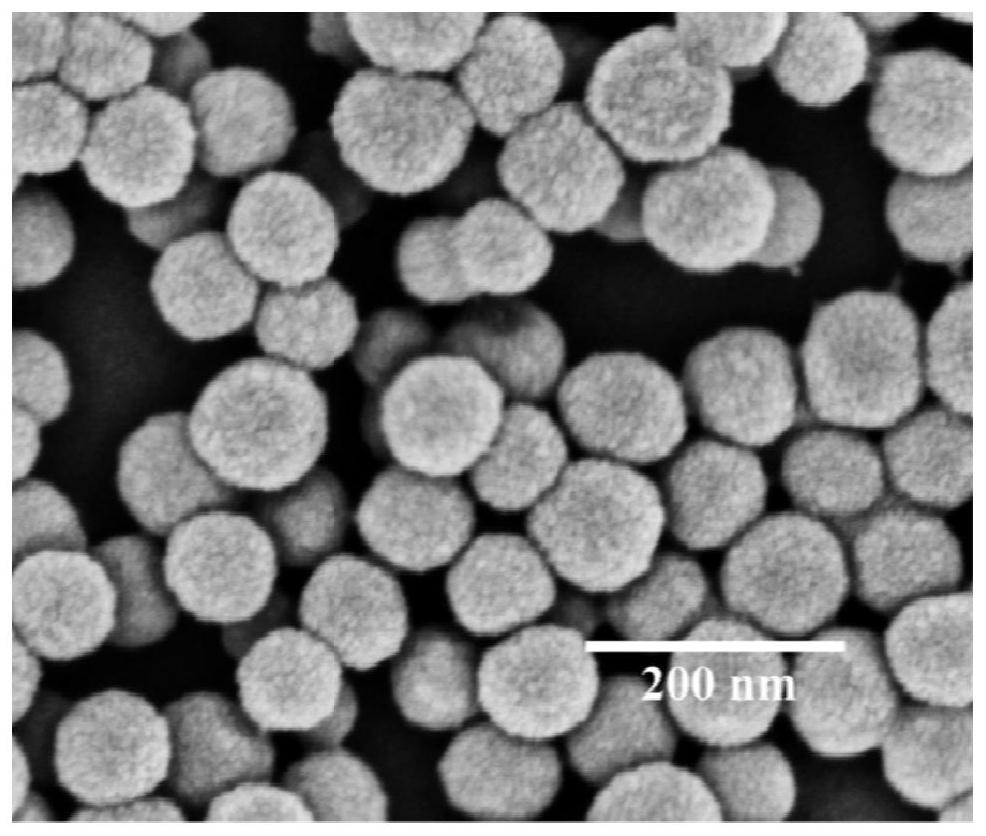

[0037] A high-efficiency preparation method of hydrothermal nano-carbon spheres, comprising the following steps:

[0038] S1, configure the concentration of glucose solution to be 0.8M, the amount of dispersant poly(4-styrenesulfonic acid-co-maleic acid) sodium salt (PSSMA) is 0.5% of the amount of glucose, and stir to obtain a mixed solution;

[0039] S2. Take 60 mL of the mixed solution configured in step S1 and put it into a 100 mL autoclave. After the autoclave is sealed, nitrogen gas is introduced through the air inlet so that the initial pressure in the still is 3.0 MPa;

[0040] S3. Heating the autoclave in step S2 to 180° C. and then keeping the temperature for 6 hours. After the reaction, naturally cool to room temperature to obtain a carbon nanosphere solution;

[0041] S4. Separate the nano-carbon sphere solution obtained in S3 with a centrifugation rate of 15000r / min for 20 minutes, centrifuge with deionized water, and ultrasonically disperse and wash three times, ...

Embodiment 3

[0044] A high-efficiency preparation method of hydrothermal nano-carbon spheres, comprising the following steps:

[0045] S1, configure the concentration of glucose solution to be 0.7M, the amount of dispersant poly(4-styrenesulfonic acid-copolymerization-maleic acid) sodium salt (PSSMA) is 0.8% of the amount of glucose, and stir to obtain a mixed solution;

[0046] S2, get 50mL of the mixed solution configured in step S1, put it into a 100mL autoclave, and after the autoclave is sealed, feed nitrogen through the air inlet so that the initial pressure in the still is 2.5MPa;

[0047] S3. Heating the autoclave in step S2 to 200° C. and then keeping the temperature for 3 hours. After the reaction, naturally cool to room temperature to obtain a carbon nanosphere solution;

[0048] S4. Separate the nano-carbon sphere solution obtained in S3 at a centrifugal rate of 20,000 r / min for 50 minutes, centrifuge with deionized water, and ultrasonically disperse and wash three times, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com