Method for preparing dicyclohexylcarbodiimide by using vilsmeier reagent

A technology of dicyclohexylcarbodiimide and dicyclohexylurea, which is applied in the field of preparing dicyclohexylcarbodiimide, can solve problems such as insufficiently stable yield, insufficiently high yield, and adverse effects of industrial production, and achieve operational The effect of simplicity and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

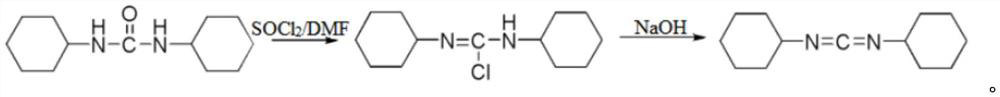

Method used

Image

Examples

Embodiment 1

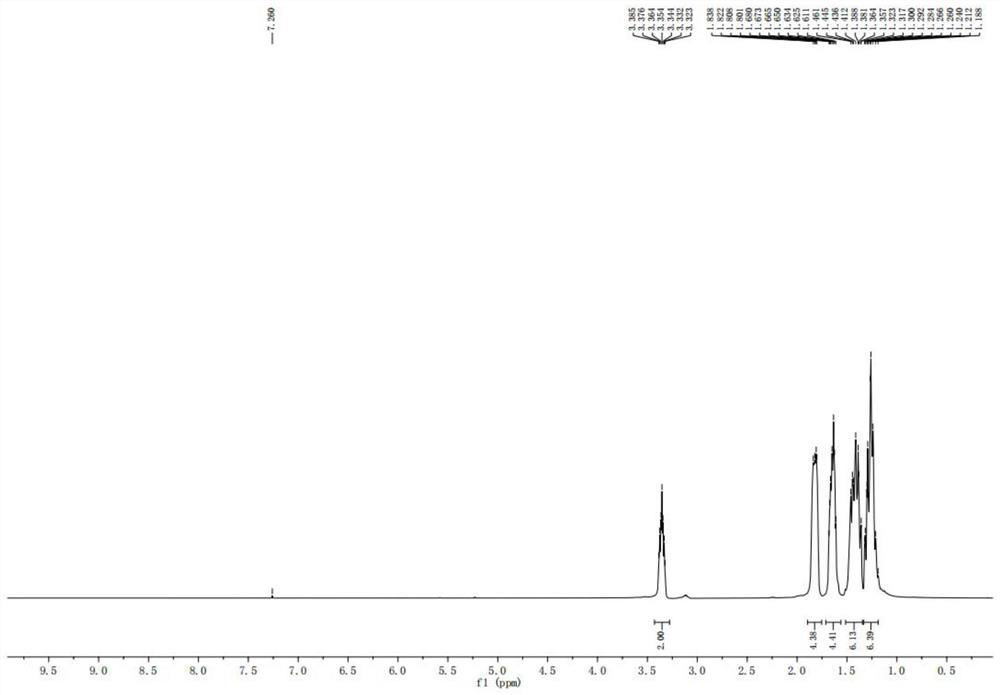

[0022] Add 3g DMF to 40g SOCl 2 , stirred for 30min and set aside. Put 50g of DCU and 400mL of dichloromethane into a dry 500mL three-neck flask, and stir evenly. will prepare SOCl 2 / DMF solution was added dropwise to the there-necked flask, the time for the controlled addition was 2h, and the temperature for the addition was 10°C. After the addition, the stirring reaction was continued for 5h. After the reaction, the reaction solution was added dropwise to 410g of a 10% NaOH aqueous solution. Then suction filtration, the filtrate was distilled under normal pressure to remove the solvent, and then distilled under reduced pressure at a pressure of 1.35-1.54KPa to collect fractions at 153-156°C and vacuum-dried to obtain the product with a purity of 95.8% and a yield of 87.5%.

[0023] Carry out nuclear magnetic test to above-mentioned product, record proton nuclear magnetic spectrum spectrogram such as figure 1 shown.

Embodiment 2

[0025] Add 4.5g DMF to 52g SOCl 2 , stirred for 30min and set aside. Put 50g of DCU and 300mL of dichloromethane into a dry 500mL three-neck flask, and stir evenly. will prepare SOCl 2 / DMF solution is added dropwise to the three-necked flask, the dropping time is controlled to be 0.5h, the dropping temperature is 30°C, and the stirring reaction is continued for 5h after the dropping is completed. , and then suction filtered, the filtrate was distilled under normal pressure to remove the solvent, then distilled under reduced pressure at 1.35-1.54KPa to collect fractions at 153-156°C, and vacuum dried to obtain the product with a purity of 98.9% and a yield of 92.4%.

Embodiment 3

[0027] Add 3g DMF to 48g SOCl 2 , stirred for 30min and set aside. Put 50g of DCU and 500mL of dichloromethane into a dry 500mL three-neck flask, and stir evenly. will prepare SOCl 2 / DMF solution is added dropwise to the three-necked flask, the dropping time is controlled to be 0.5h, the dropping temperature is 30°C, and the stirring reaction is continued for 2h after the dropping is completed. , and then suction filtered, the filtrate was distilled under normal pressure to remove the solvent, then distilled under reduced pressure at 1.35-1.54KPa to collect fractions at 153-156°C, and vacuum dried to obtain the product with a purity of 96.7% and a yield of 90.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com