Acanthopanax senticosus extract composition, extraction method and acanthopanax senticosus injection

A technology of Acanthopanax senticosus extract and Acanthopanax senticosus injection, which is applied in the field of Acanthopanax senticosus extract composition, can solve the problems of cumbersome process, long extraction cycle, and many steps, and achieve less process steps, reduce cerebral edema, The effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

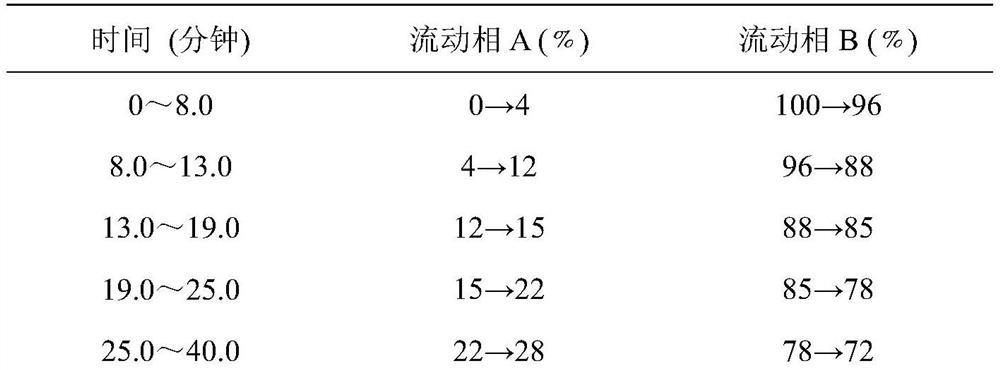

Method used

Image

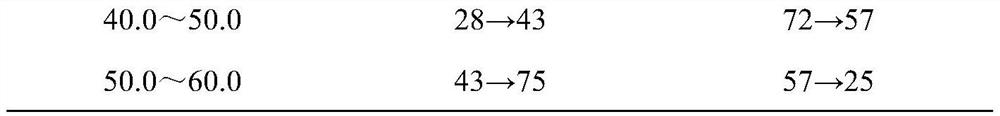

Examples

Embodiment 1

[0026] Preparation of Acanthopanax extract composition:

[0027] (1) crushing: the roots and stems of Acanthopanax senticosus are crushed to make crushed material;

[0028] (2) Add 5 kg of Acanthopanax senticosus crushed material, add 12 times the amount of water to reflux extract three times, each time for 1 hour, filter, combine the filtrate, and concentrate under reduced pressure at 60 ° C to a concentrated paste with a relative density of 1.10;

[0029] (3) Add ethanol until the alcohol content reaches 85%, let it stand for 12 hours, filter and collect the filtrate, recover the ethanol under reduced pressure, and obtain the alcohol precipitated paste;

[0030] (4) Adjust the pH value of the alcohol precipitation paste to 5.0, and use a macroporous resin column for adsorption. The flow rate of the upper liquid is 2BV / h for adsorption, and the tail liquid is collected, and then eluted with 60% ethanol. The amount of eluent is 2BV. The flow rate is 1.5BV / h, and the eluate is...

Embodiment 2

[0034] Preparation of Acanthopanax extract composition:

[0035] (1) crushing: the roots and stems of Acanthopanax senticosus are crushed to make crushed material;

[0036] (2) Add 5 kg of Acanthopanax senticosus powder into 11 times the amount of water to reflux and extract three times, each time for 1.5 hours, filter, combine the filtrates, and concentrate under reduced pressure at 60 ° C to a concentrated paste with a relative density of 1.10;

[0037] (3) Add ethanol until the alcohol content reaches 85%, let it stand for 12 hours, filter and collect the filtrate, recover the ethanol under reduced pressure, and obtain the alcohol precipitated paste;

[0038] (4) Adjust the pH value of the alcohol precipitation paste to 5.5, and use a macroporous resin column for adsorption, and the flow rate of the upper liquid is 2BV / h for adsorption, and the tail liquid is collected; then, it is eluted with 50% ethanol, and the amount of eluent is 2BV, The flow rate is 1.5BV / h, the elua...

Embodiment 3

[0042] Preparation of Acanthopanax extract composition:

[0043] (1) crushing: the roots and stems of Acanthopanax senticosus are crushed to make crushed material;

[0044] (2) Add 5 kg of Acanthopanax senticosus crushed material to 10 times the amount of water to reflux and extract three times, each time for 2 hours, filter the combined filtrate, and concentrate under reduced pressure at 60 ° C to a concentrated paste with a relative density of 1.10;

[0045] (3) Add ethanol until the alcohol content reaches 85%, let it stand for 12 hours, filter and collect the filtrate, recover the ethanol under reduced pressure, and obtain the alcohol precipitated paste;

[0046] (4) Adjust the pH value of the alcohol precipitation paste to 6.0, and use a macroporous resin column for adsorption, and the flow rate of the upper liquid is 2BV / h for adsorption, and the tail liquid is collected; then, it is eluted with 65% ethanol, and the amount of eluent is 2BV, The flow rate is 1.5BV / h, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com