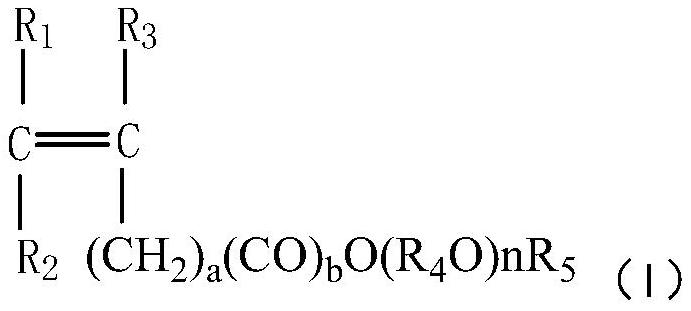

Polycarboxylate superplasticizer and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, applied in the field of polycarboxylic acid water reducing agent, can solve the problems of shielding, difficult to control molecular structure, unable to give full play to the role of POSS group, etc., and achieve simplified use process and good mud resistance. and early strength function, the effect of easy control of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Step 1, the preparation of heptaisobutylaminopropyl POSS

[0043] The preparation process of heptaisobutylaminopropyl POSS is described in the master's thesis of Huazhong University of Science and Technology Han Chang (Han Chang. Synthesis of MRI contrast agent ligands containing monoamino POSS [D]. Wuhan: Huazhong University of Science and Technology, 2012.) method is carried out.

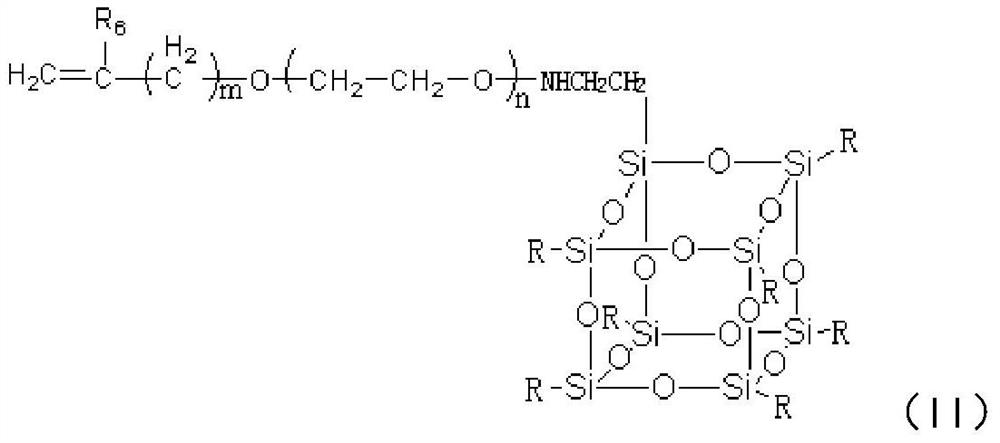

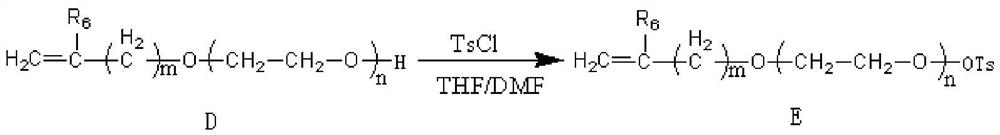

[0044] Step 2: Preparation of the second polyether macromonomer modified by POSS

[0045] 50 g of polyether macromonomer HPEG with a weight average molecular weight of 2400 was dissolved in 100 ml of THF / DMF, and 30 ml of triethanolamine solution containing 4.032 g of p-toluenesulfonyl chloride (TsCl) was added dropwise at 0°C. After stirring at 20°C for 12 hours, the solution with a pH value of 7-8 was neutralized with hydrochloric acid, concentrated by rotary evaporation, the filtrate was refrigerated at 4°C overnight, and suction filtered. The sample obtained by suction filtration was ...

Embodiment 1

[0049] The second polyether macromonomer and 45g HPEG (molecular weight 2400) of 45g HPEG-POSS modification are placed in reactor, add 90g water and dissolve, add 1.2g massfraction in reactor and be the hydrogen peroxide of 27.5%, be warming up to Stir well at 20°C. Add 10g of water to 10g of acrylic acid to dissolve to prepare drop solution X; add 0.2g of vitamin C and 0.38g of thioglycolic acid to 30g of water to prepare drop solution Y; control the temperature in the reactor at 30± At 2°C, start to add dropwise solutions X and Y at the same time, and the dropping time is 3h and 3.5h respectively. Neutralize until the pH value is 6-7, and the obtained polycarboxylate water reducer is named PCE1.

Embodiment 2

[0051] Put 35g VPEG-POSS and 45g TPEG (molecular weight 3600) in the reactor, add 80g water to dissolve, add 1.2g hydrogen peroxide with a mass fraction of 27.5% into the reactor, heat up to 20°C and stir evenly. Add 10g of water to 20g of acrylic acid to dissolve to prepare drop solution X; add 0.2g of vitamin C and 0.38g of thioglycolic acid to 30g of water to prepare drop solution Y; control the temperature in the reactor at 30± At 2°C, start to add dropwise solutions X and Y at the same time, and the dropping time is 3h and 3.5h respectively. Neutralize to a pH value of 6-7, and the obtained polycarboxylate water reducer is named PCE2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com