Polyamide barrier material and preparation method thereof

A barrier material, polyamide technology, applied in the field of polymers, can solve the problems of expensive raw material cost, poor strength, no obvious improvement of barrier performance, etc., and achieve excellent barrier performance and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

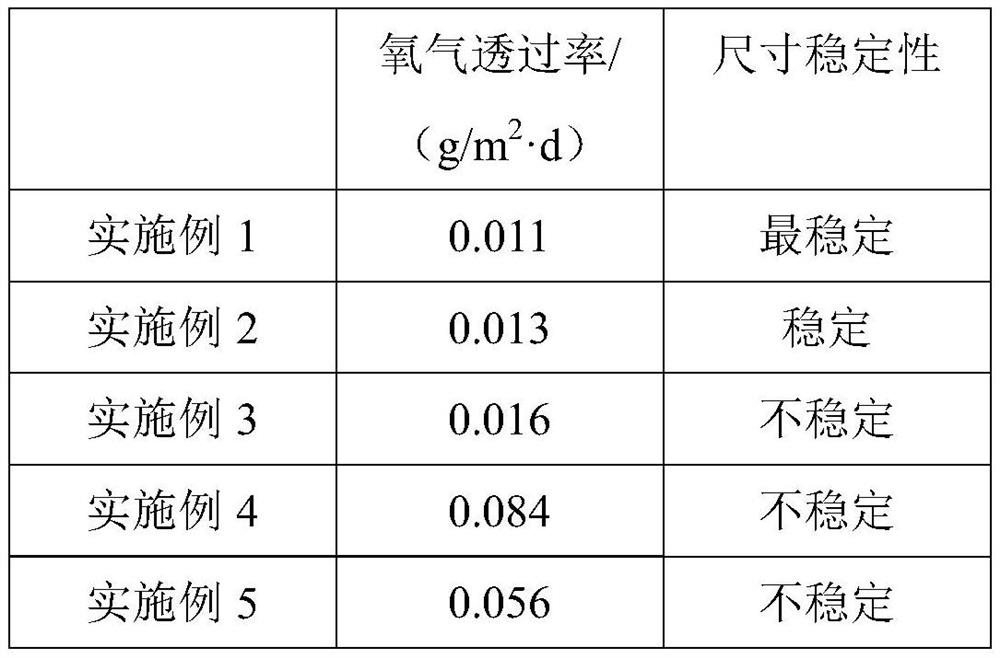

Examples

preparation example Construction

[0061] A second aspect of the present invention provides a method for preparing a polyamide barrier material, the preparation method at least including the following steps:

[0062] (1) Add polyamide resin, thermoplastic polyester, antioxidant, toughening agent, lubricant, and dispersant to a high-speed mixer and mix evenly;

[0063] (2) Put the mixture obtained in the step (1) in a twin-screw machine, extrude and granulate, and the melt pressure is 10-20 MPa.

Embodiment 1

[0069] Provided is a polyamide barrier material. In parts by weight, the preparation raw materials include: 56 parts of polyamide resin, 38 parts of thermoplastic polyester, 1.5-2.5 parts of antioxidant, 1 part of toughening agent, 1.5 parts of lubricant, dispersion 0.5 parts of the agent.

[0070] The polyamide resin is nylon MXD6. The density of the nylon MXD6 is 1.19g / cm 3 . The nylon MXD6 can be obtained commercially, the manufacturer is Shanghai Yingguo Industry Co., Ltd., and the brand name is nylon MXD6AP250.

[0071] The thermoplastic polyester is polyethylene terephthalate. The polyethylene terephthalate can be obtained commercially, the manufacturer is DuPont USA, and the brand name is PET DuPont 19045 USA.

[0072] The antioxidant is N,N bis[3(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hexamethylenediamine.

[0073] The toughening agent is POE grafted maleic anhydride.

[0074] The lubricant is N,N'-ethylene bisstearamide.

[0075] The dispersant is montan w...

Embodiment 2

[0080] Provided is a polyamide barrier material, prepared raw materials in parts by weight: 70 parts of polyamide resin, 50 parts of thermoplastic polyester, 3 parts of antioxidant, 1.5 parts of toughening agent, 2 parts of lubricant, 1 part of dispersant share.

[0081] The polyamide resin is nylon MXD6. The density of the nylon MXD6 is 1.19g / cm 3 . The nylon MXD6 can be obtained commercially, the manufacturer is Shanghai Yingguo Industry Co., Ltd., and the brand name is nylon MXD6AP250.

[0082] The thermoplastic polyester is polyethylene terephthalate. The polyethylene terephthalate can be obtained commercially, the manufacturer is DuPont USA, and the brand name is PET DuPont 19045 USA.

[0083] The antioxidant is N,N bis[3(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hexamethylenediamine.

[0084] The toughening agent is POE grafted maleic anhydride.

[0085] The lubricant is N,N'-ethylene bisstearamide.

[0086] The dispersant is montan wax.

[0087] The preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com