Streamline tunnel type turbocharger adopting external contour type air bearing

A turbocharger, air bearing technology, applied in the components of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc., can solve the problem of not deep, no application examples, streamline tunnel There are few problems such as less research on turbocharger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

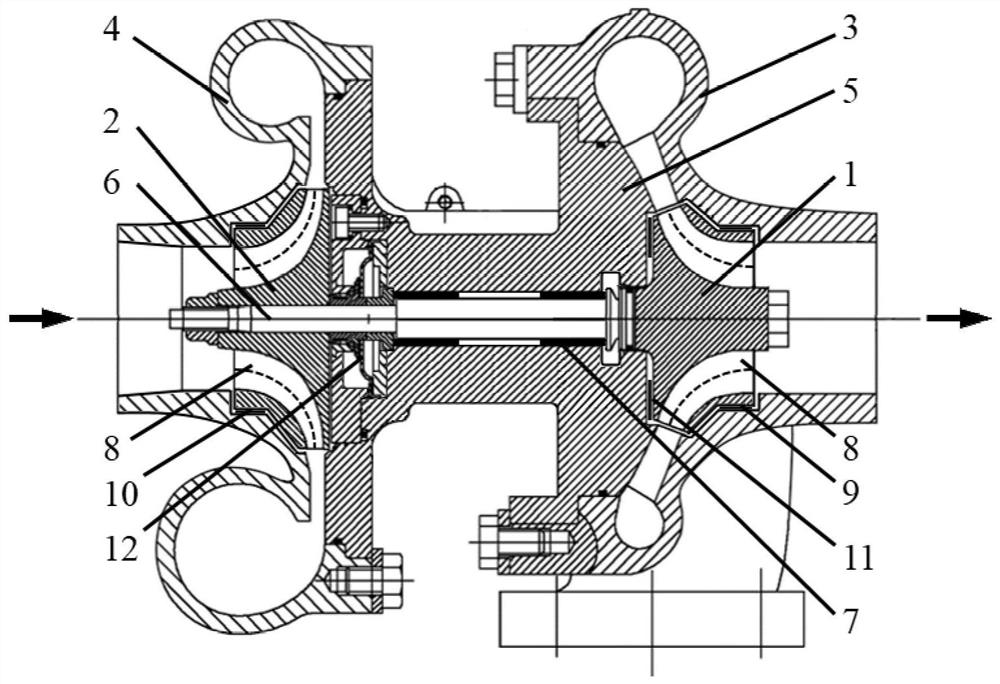

[0027] Such as figure 1 As shown, a streamlined tunnel turbocharger adopting an outer profile air bearing includes a streamlined tunnel turbine 1, a streamlined tunnel compressor wheel 2, a turbine shell 3, a compressor shell 4, and an intermediate shell 5 And the shaft 6; the streamline tunnel turbine 1 and the streamline tunnel compressor wheel 2 are respectively installed on both ends of the shaft 6 to form a supercharger rotor.

[0028] The streamline tunnel turbine 1 and the streamline tunnel compressor wheel 2 are closed rotating machines, and the structures of the two can be exactly the same, usually consisting of dozens of streamline tunnels 8, the streamline tunnels 8 Including the centerline of the streamline tunnel, the centerline of each streamline tunnel is a three-dimensional curve, and the normal sections of the streamline tunnels 8 are one of circular and / or elliptical, when each of the streamline tunnels 8 When the normal section is an ellipse, the major axis...

Embodiment 2

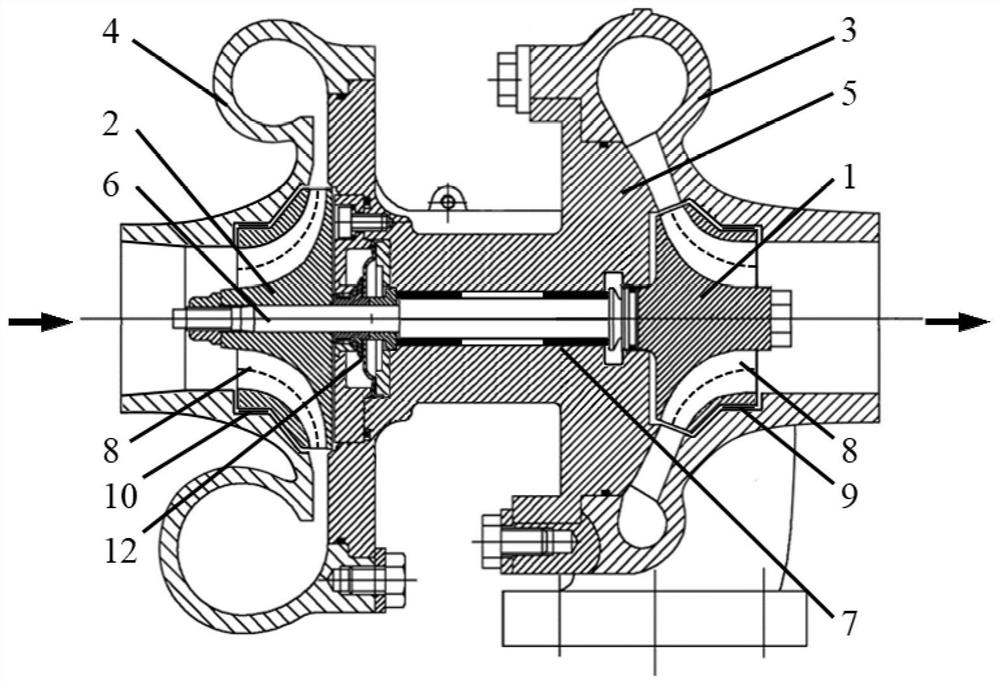

[0034] Such as figure 2 As shown, compared with Embodiment 1, the supercharger rotor has an outer profile thrust pressure air bearing 11 and a traditional oil-impregnated thrust bearing assembly 12 double thrust bearings to balance the axial load. In this embodiment, the outer profile thrust is canceled Compressed air bearings only use the traditional oil-impregnated thrust bearing assembly 12 to balance the axial load. This method is suitable for the situation where the traditional oil-impregnated thrust bearing assembly 12 has sufficient supporting force, reduces the number of parts and reduces the cost.

Embodiment 3

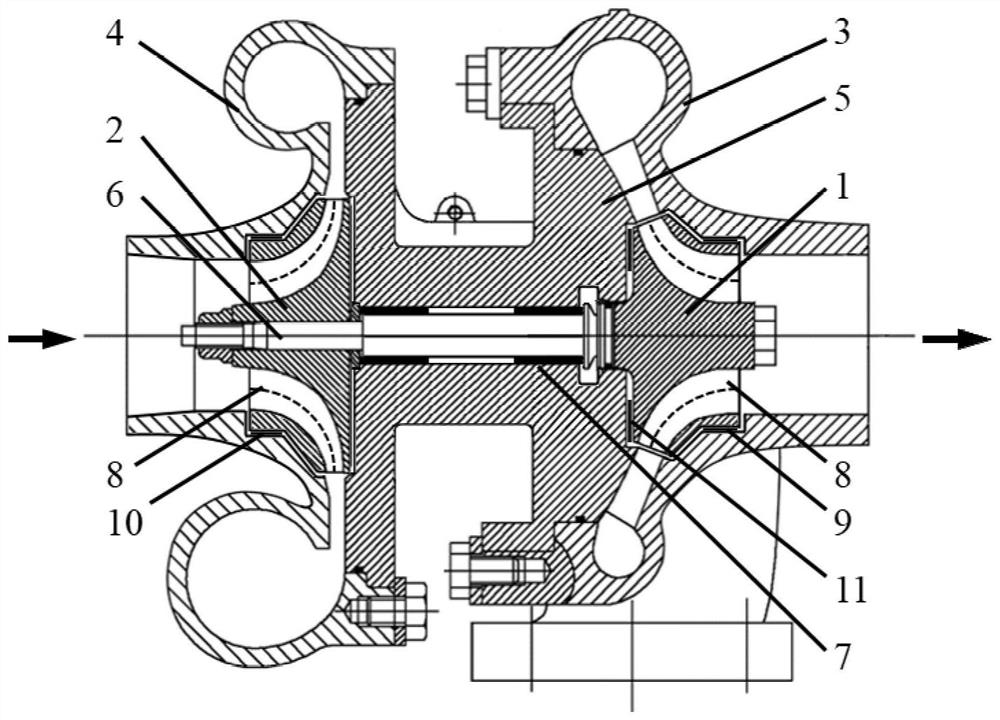

[0036] Such as image 3 As shown, compared with Embodiment 1, the supercharger rotor has an outer profile thrust pressure air bearing 11 and a traditional oil-impregnated thrust bearing assembly 12 double-thrust bearings to balance the axial load. In this embodiment, the traditional oil-impregnated thrust is cancelled. For the bearing assembly, only the outer contour thrust pressure air bearing 11 is used to balance the axial load. This method is suitable for the case where the outer contour thrust pressure air bearing 11 has sufficient supporting force, and greatly reduces the complexity of the shafting structure and the middle shell 5. Reduce processing difficulty and cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com