Hydrostatic bearing and hydrostatic guide rail assembly

A technology of hydrostatic bearing and hydrostatic guide rail, applied in the directions of hydrostatic bearing, bearing, shaft and bearing, etc., can solve the problems of short life, high cost, difficult realization, etc., and achieve the effect of simple structure and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

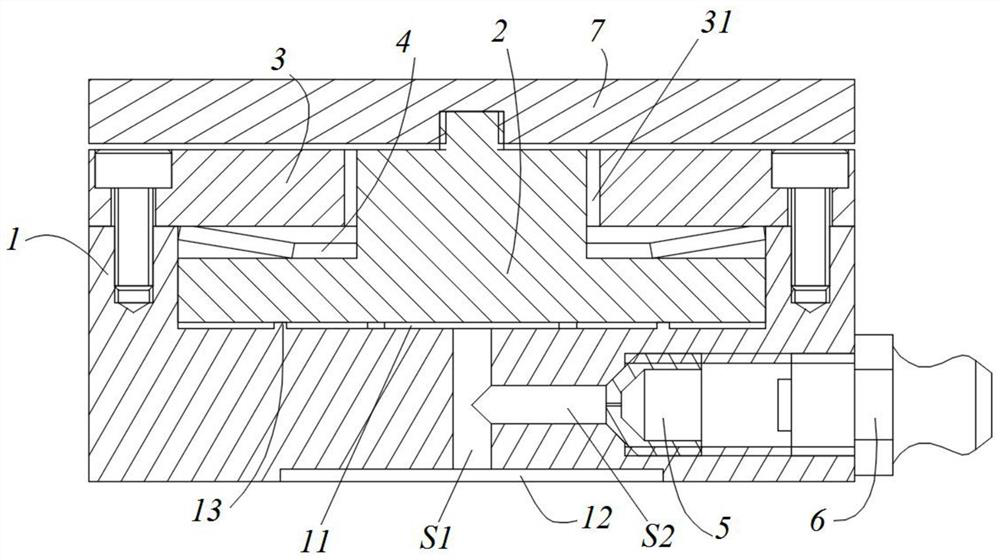

[0031] like figure 1 As shown, the hydrostatic bearing in this embodiment includes:

[0032] The support block 1 has a sub-chamber 11 on its upper part and a main chamber 12 on its lower part, and the sub-chamber 11 and the main chamber 12 are communicated through the first channel S1. Further, the main chamber 12 The depth is 1-3 mm (preferably 2 mm), and at least one limiting boss 13 is provided at the bottom of the sub-chamber S1. In this embodiment, the limiting boss 13 and the support block 1 can be integrally formed. And the height of the stop protrusion 13 is 0.2-1.0mm, preferably 0.5mm; meanwhile, the diameter of the secondary chamber 11 is 20-35mm (preferably 25mm), and the diameter of the main chamber 12 is 10-25mm ( preferably 15 mm);

[0033] A cover plate 3, which is set on the support block 1, and is detachably connected to the support block 1 by bolts, etc., and the cover plate 3 is provided with an opening communicating with the secondary chamber S1 31;

[...

Embodiment 2

[0045] The only difference between this embodiment and Embodiment 1 is that in this embodiment, the bottom area of the auxiliary chamber 11 is 5-10% (preferably 6-8%, preferably 6-8%) larger than the effective bearing area of the bottom surface of the support block 1. Particularly preferred is 6.5%).

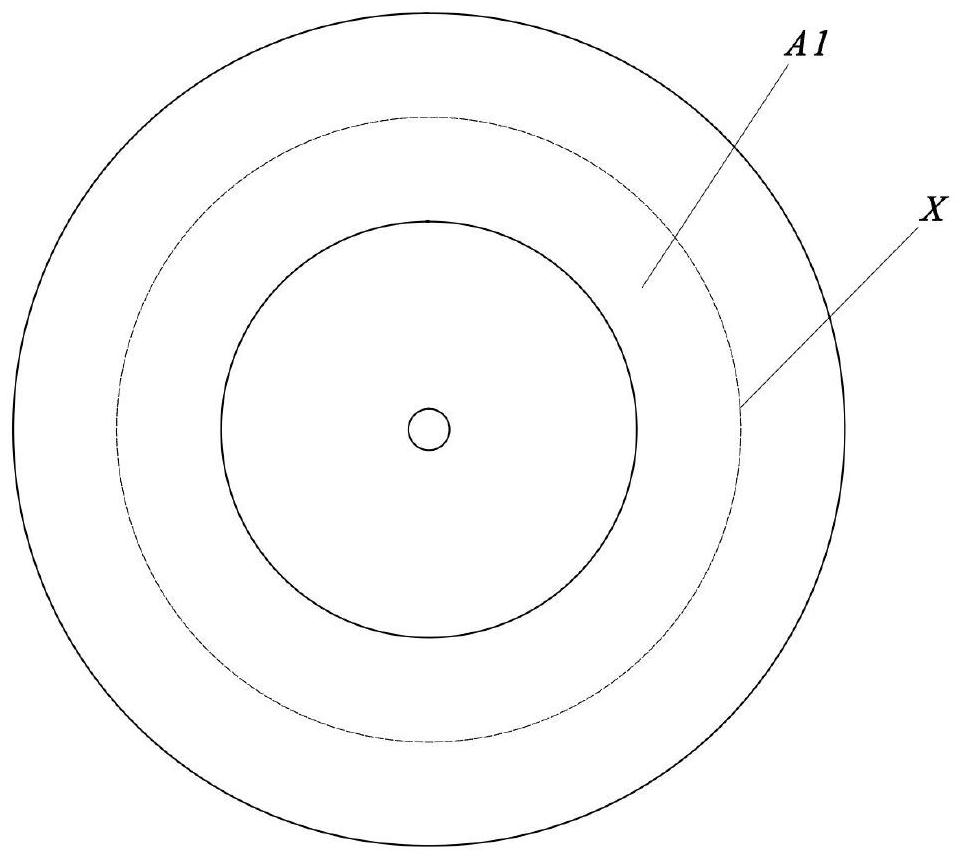

[0046] like image 3 As shown, the effective bearing area of the bottom surface of the support block 1 is the area of the area A1 surrounded by the center line X of the oil sealing surface, and the force of the oil film acting on the bottom surface of the support block 1 is mainly the oil pressure in the chamber 12 and the effective load bearing area. The product of the area. Because the bottom area of the auxiliary chamber 11 is 5-10% larger than the effective bearing area of the bottom surface of the support block 1, and the main chamber 12 communicates with the oil pressure in the auxiliary chamber 11, so that the internal oil pressure of the hydrostatic bearing ...

Embodiment 3

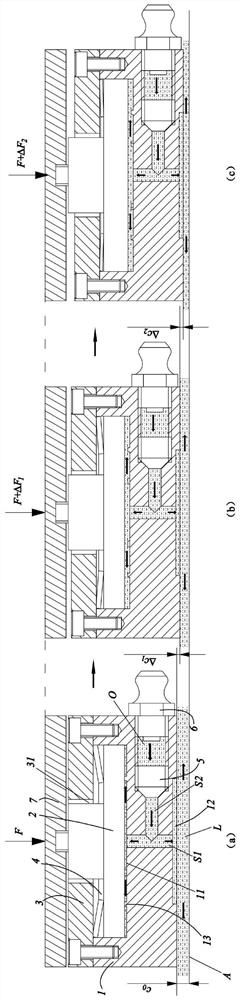

[0049] This embodiment provides a static pressure rail assembly, such as Figure 4 As shown, it includes: guide rail 21, slide plate 8, pressure gauge 9, regulating valve 10, hydraulic pump 20 and the hydrostatic bearing described in Embodiment 1 or 2;

[0050] Wherein, the slide plate 8 is connected to the bearing disc 7, the guide rail 21 is in clearance fit with the bottom surface of the support block 1, and the high-pressure oil in the external oil supply equipment flows into the restrictor 5 through the adapter 6, and then passes through the restrictor. The flow device 5 is throttled so that the pressure of the high-pressure oil is reduced to become low-pressure oil, and the low-pressure oil fills the entire main chamber 12 and the auxiliary chamber 11 through the second channel S2 and the first channel S1, and the oil on the bottom surface of the support block 1 An oil film is formed between the guide rail 10 to support the upper slide 8.

[0051] Further, the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com