Hypersonic flow field pulsating density measuring system and method

A density measurement, hypersonic technology, used in measurement devices, aerodynamic tests, and testing of machine/structural components, etc., can solve the problems that the sensor is difficult to meet the thermal load and shock load, and the sensor response frequency cannot cover the frequency band, etc. The effect of high utilization rate, easy adjustment and compact system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

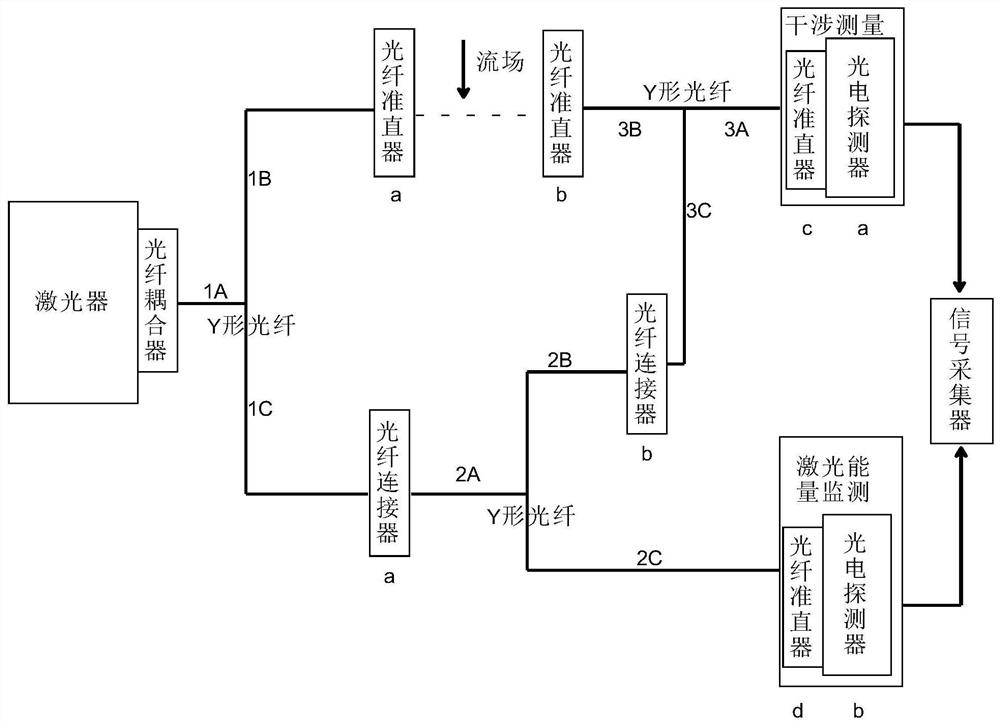

[0035] Such as figure 1 As shown, a hypersonic flow field pulsation density measurement system includes a laser energy monitoring system, an interferometry system,

[0036] More specifically, it includes a laser, a fiber coupler, a Y-shaped fiber, a fiber connector, a fiber collimator, a photodetector and a signal collector, the laser is connected to the fiber coupler,

[0037] In the laser energy monitoring system, the fiber coupler is connected through the Y-shaped optical fiber 1A, the Y-shaped optical fiber 1C and the optical fiber connector a, and the optical fiber connector a is sequentially connected through the Y-shaped optical fiber 2A, the Y-shaped optical fiber 2C and the laser energy monitoring assembly;

[0038] The interferometric measurement system includes an interferometric reference optical path and an interferometric measurement optical path,

[0039] In the measurement optical path of the interference, the fiber coupler is connected to the fiber collimator...

Embodiment 2

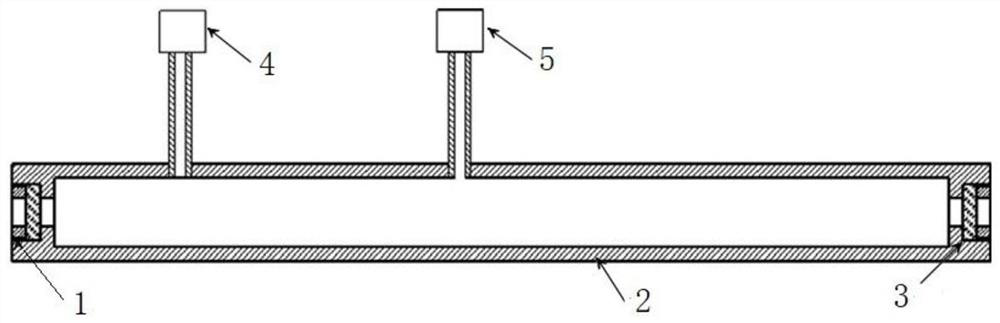

[0061] On the basis of Example 1, different from Example 1, such as figure 2 As shown, the measurement range of the pulsating density is calibrated by a calibration device, which includes a glass pressure ring, a calibration tube, quartz glass, a pressure / temperature sensor, and a vacuum pump. The two ends of the calibration tube are respectively provided with a glass pressure ring and a quartz The glass and the middle of the calibration tube are respectively provided with pressure / temperature sensors and vacuum pumps at certain intervals, and the pressure / temperature sensors and vacuum pumps are arranged along the direction perpendicular to the axis of the calibration tube.

[0062] Quartz glass is installed on both sides of the calibration tube to simulate the measurement area; the pressure sensor is used to record the pressure in the calibration tube; the temperature sensor is used to record the temperature in the calibration tube; the vacuum pump is used to change the pres...

Embodiment 3

[0069] On the basis of Example 1, further, a calibration device is set between the fiber collimator a and the fiber collimator b, and the measurement range of the pulsation density is calibrated by a calibration device, and the calibration device includes a glass pressure ring, a calibration tube, quartz glass, pressure / temperature sensor, and vacuum pump. The two ends of the calibration tube are respectively provided with glass pressure rings and quartz glass, and the middle of the calibration tube is respectively provided with a pressure / temperature sensor and a vacuum pump at a certain distance. Both the sensor and the vacuum pump are arranged along a direction perpendicular to the axis of the calibration tube.

[0070] A hypersonic flow field pulsation density measurement method, using the hypersonic flow field pulsation density measurement system, specifically includes the following steps:

[0071] Laser energy monitoring: the laser is transmitted through Y-shaped optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com