Four-ball friction test evaluation method for adhesion performance of asphalt and coarse aggregate

An evaluation method and friction testing machine technology, applied in the direction of analyzing materials, instruments, measuring devices, etc., can solve the problems of ineffective evaluation of asphalt adhesion, shedding, and large influence, so as to avoid the influence of human subjective factors and make the preparation simple Convenience, the effect of avoiding interference effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preprocessing of coarse aggregate

[0041] (1-1) Limestone is used as the aggregate. First, coarse aggregates with large particle sizes greater than 12mm are initially selected to measure the total area of the coarse aggregates;

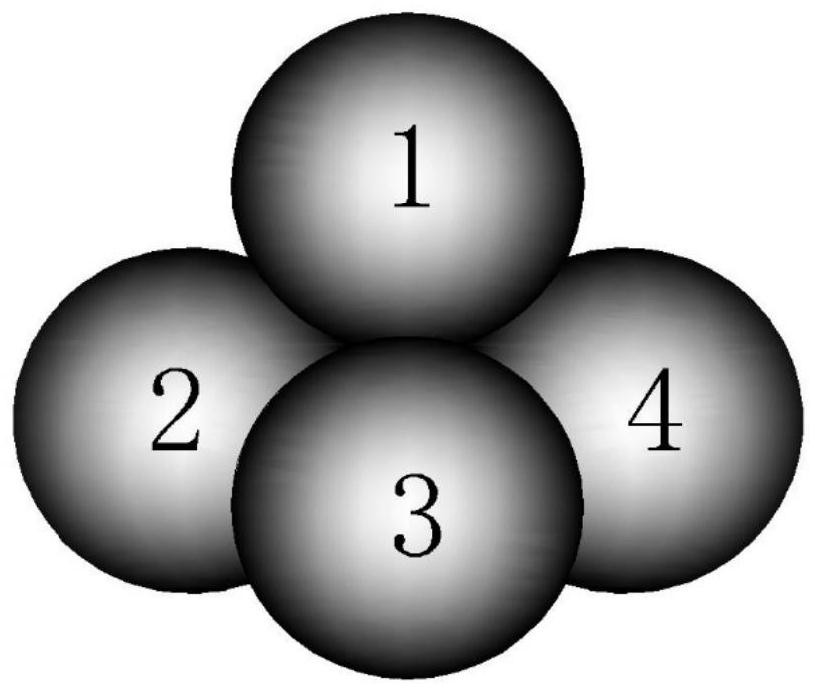

[0042] (1-2) Process the selected large-size coarse aggregate with a rounder, process 5 balls with a diameter of 12 mm, and ensure that the surface roughness Ra of the coarse aggregate ball is less than 25.0 μm;

[0043] (2) Asphalt coating and cooling treatment

[0044] (2-1) Place the coarse aggregate balls in step (1) in an oven at 105°C and heat for 1 hour;

[0045] (2-2) Put the heated coarse aggregate balls into the pre-heated asphalt with a small colander. The asphalt is SBS modified asphalt, and the temperature of the asphalt heating is controlled at 160°C; The ball is completely covered with asphalt film;

[0046] (2-3) Gently take out the sample, and place it in a closed glass container with a nitrogen content of 90% by volume...

Embodiment 2

[0060] The method of embodiment 2 and embodiment 1 is identical, and difference is that in described step (1-1), coarse aggregate adopts the aggregate of 3 kinds of different lithologies, respectively granite, basalt, quartzite; Step (2-2 ) asphalt adopts SBR modified asphalt. The adhesion of three lithological aggregates to SBR modified asphalt was compared. The results are shown in Table 4.

[0061] Table 4 Example result two

[0062]

[0063] It can be seen from the experimental results that the adhesion grades of the three lithological aggregates obtained by the present invention are granite>basalt>quartzite; and the adhesion of the three lithological aggregates is the same when using the current standard boiling method. Therefore, the present invention can effectively distinguish and judge the order of good and bad adhesion of aggregates.

Embodiment 3

[0065] The method of embodiment 3 and embodiment 1 is identical, aggregate adopts limestone; Difference is that in described step (2-2), asphalt adopts SBS modified asphalt, SBR modified asphalt and rubber modified asphalt, the temperature of asphalt heating The temperature is controlled at 160°C; the adhesion of three kinds of asphalt to limestone aggregates is compared. The results are shown in Table 5.

[0066] Table 5 Example result three

[0067]

[0068]

[0069] As can be seen from the experimental results, adopt the present invention to obtain three kinds of asphalt experimental results and the adhesion rank order is rubber modified asphalt>SBS modified asphalt>SBR modified asphalt; Adhesion is the same as that of permanent asphalt. Therefore, the present invention can effectively distinguish and judge the order of good and bad asphalt adhesion.

[0070] In addition, although there is currently a method for testing the load-carrying capacity of a lubricant wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com