Preparation method of long-life neutral zinc-iron flow battery

A flow battery, long-life technology, used in water-based electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve problems such as low Coulomb efficiency and poor cycle life, achieve good application prospects, low cost, and solve the problem of rapid capacity decline Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In the specific implementation process, the preparation method of the long-life neutral zinc-iron flow battery of the present invention includes the following process and testing steps:

[0032] (1) Preparation of positive electrode electrolyte (ferricyanide solution): use deionized water to prepare a certain concentration of ferricyanide (such as: K 3 Fe(CN) 6 、K 4 Fe(CN) 6 、Na 3 Fe(CN) 6 etc.) solutions and halides (such as: NaBr, KBr, CaBr 2 , MgBr2 , NaCl, KCl, MgCl 2 , CaCl 2 , NaI, KI, AgI, etc.) solution.

[0033] (2) Preparation of negative electrode electrolyte: use deionized water to prepare a series of halides of different concentrations (such as: NaBr, KBr, CaBr 2 , MgBr 2 , NaCl, KCl, MgCl 2 , CaCl 2 , NaI, KI, AgI, etc.) solution.

[0034] (3) Battery assembly: immerse a certain amount of ion-exchange membrane in a certain concentration of KOH (or NaOH) aqueous solution (0.1-5mol / L), cook at a constant temperature of 50-100°C for 1-3 hours to o...

Embodiment 1

[0041] In this embodiment, the preparation method of the long-life neutral zinc-iron flow battery includes the following process and testing steps:

[0042] (1) Preparation of electrolyte:

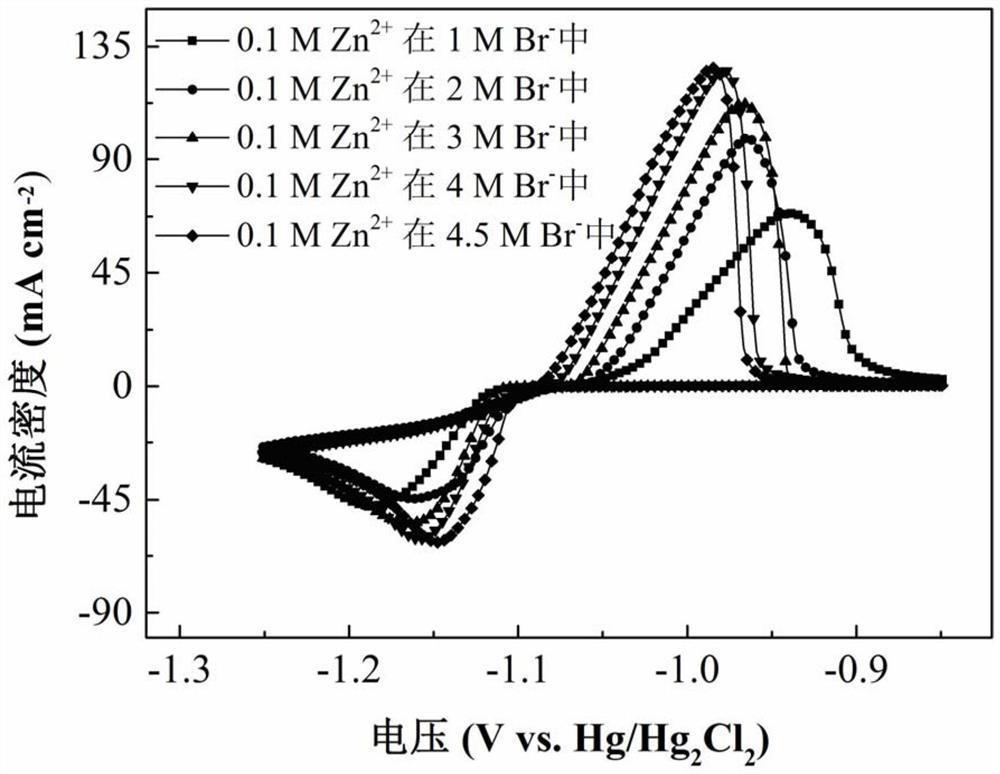

[0043] Prepare 0.1mol L -1 K 3 [Fe(CN) 6 ] Aqueous solution 15mL is used as the positive electrode electrolyte, and the positive electrode supporting electrolyte is 3mol L -1 10 mL of KBr aqueous solution was placed in the positive electrode storage tank. Negative electrode electrolyte is 1, 2, 3, 4, 4.5mol L -1 KBr aqueous solution, get 60mL respectively and put in respective negative electrode storage tanks.

[0044] (2) Separator material processing and battery assembly

[0045] Put the metal cation exchange membrane in 1mol / L KOH alkaline aqueous solution, keep the temperature at 80°C for 1h, take it out and wash it, soak it in deionized water for later use. Take a zinc sheet with a thickness of 6 μm and cut it to a size of 3×4.5cm 2 The zinc sheet is polished clean, and used a...

Embodiment 2

[0048] In this embodiment, the preparation method of the long-life neutral zinc-iron flow battery includes the following process and testing steps:

[0049] (1) Preparation of electrolyte:

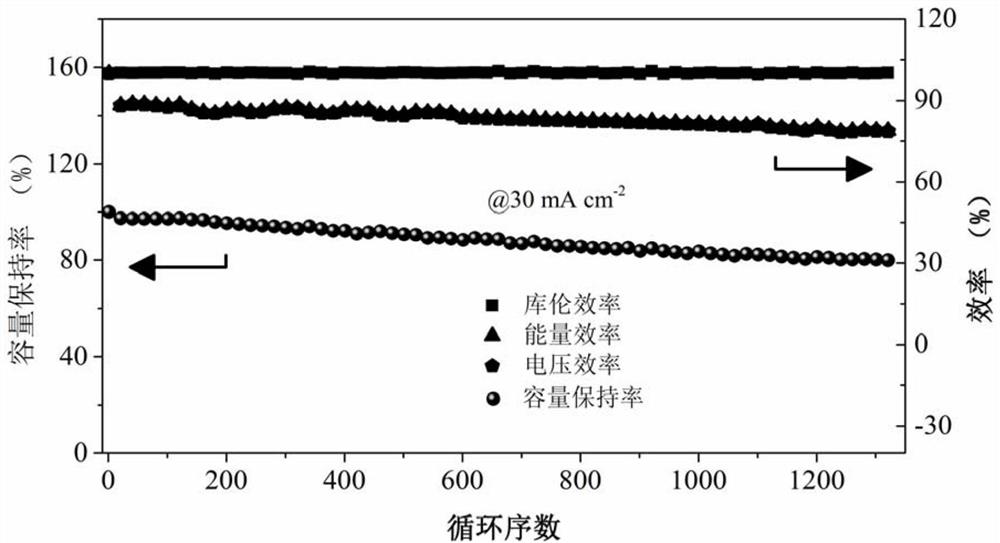

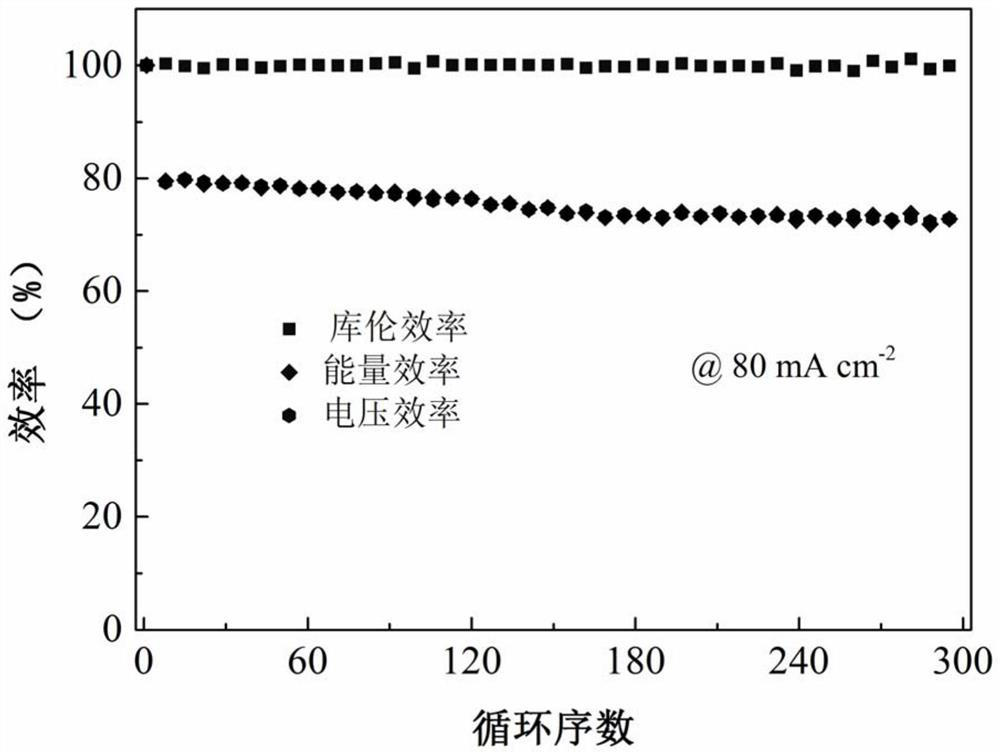

[0050] Prepare 0.1mol L -1 K 3 [Fe(CN) 6 ] Aqueous solution 15mL as positive electrode electrolyte, positive electrode supporting electrolyte is 3.0mol L -1 30 mL of KBr aqueous solution was placed in the positive electrode storage tank. The negative electrode electrolyte is 0.3mol L -1 ZnBr 2 Aqueous solution 20mL, 3.6mol L -1 40mL of KBr aqueous solution is placed in the negative electrode storage tank.

[0051] (2) Separator material processing and battery assembly

[0052] Put the metal cation exchange membrane in 1mol / L KOH alkaline aqueous solution, keep the temperature at 80°C for 1h, take it out and wash it, soak it in deionized water for later use. Take a zinc sheet with a thickness of 4 μm and cut it to a size of 3×4.5cm 2 The zinc flakes are polished clean, used as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com