MMB4 DMS nano suspension and preparation method and application thereof

A kind of nano-suspension, suspension technology, applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

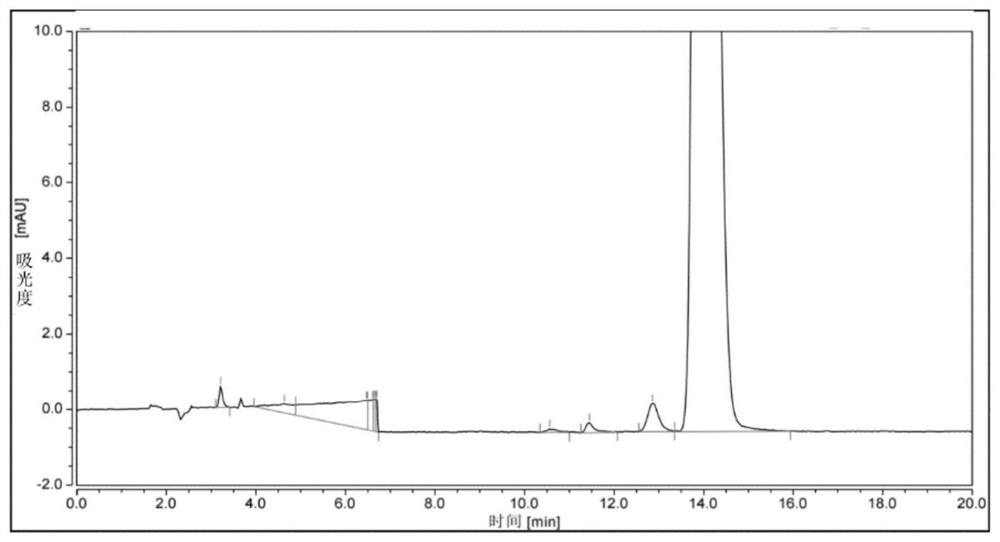

[0090] Example 1 Preparation of MMB4 DMS nanosuspension

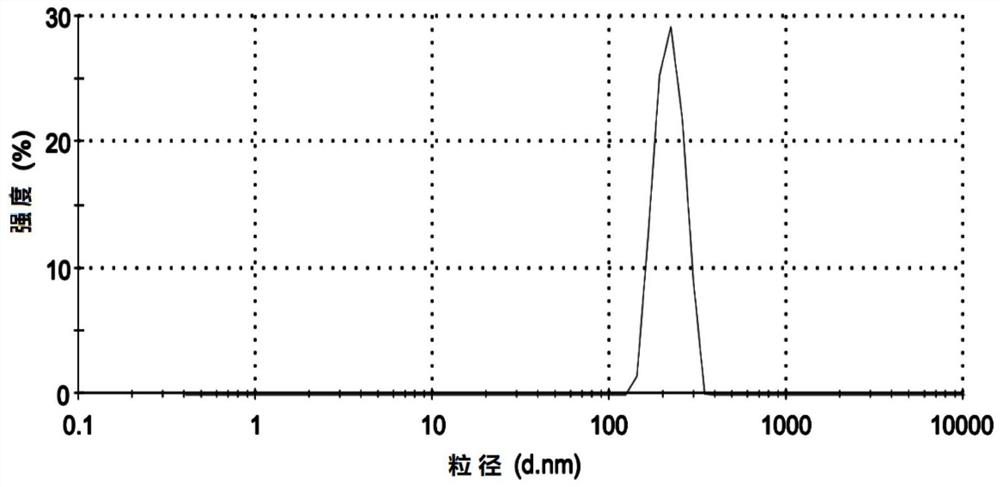

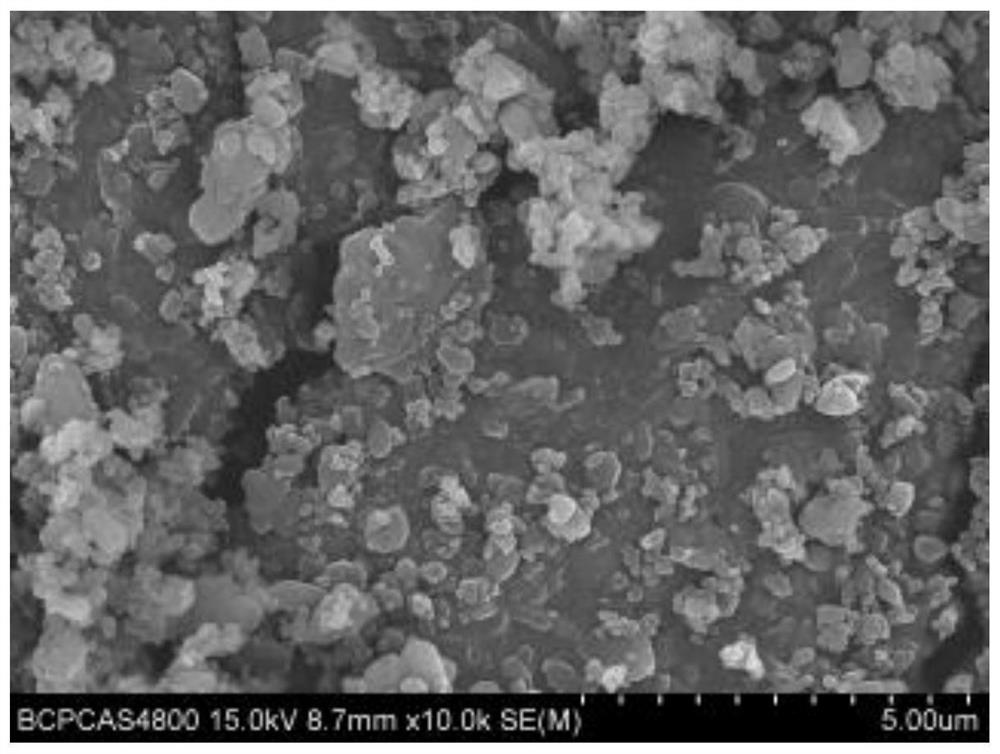

[0091] At room temperature, weigh 900g of cottonseed oil, slowly add 100g of MMB4 DMS, stir and mix; ultrasonically homogenize for 15min, ultrasonic frequency 10000rpm; pour the obtained mixture into a wet mill for grinding, temperature 28°C, initial speed 1500rpm , increase the rotation speed by 500rpm every 5 minutes until 3000rpm, and grind for 2h, that is to say. The particle size of MMB4 DMS nanoparticles is 215.8nm, the polydispersity index (PDI) is 0.282, and the viscosity of the preparation is 340mPa.s.

Embodiment 2

[0092] The preparation of embodiment 2 MMB4 DMS nanosuspension

[0093]At room temperature, 10 g of MMB4 DMS was added into 90 g of cottonseed oil under stirring at 500 rpm, and the stirring was continued for 10 min. Then the mixture was ultrasonically homogenized for 10 min at an ultrasonic frequency of 8000 rpm. Put the obtained mixture into the wet mill, put it into the wet mill, the temperature is 30°C, the initial speed is 1200rpm, and the speed is increased to 500rpm every 5 minutes until it reaches 3500rpm, and it is ground for 1.5h to obtain the final product.

[0094] The particle size of MMB4 DMS nanoparticles is 228.9nm, the polydispersity index (PDI) is 0.475, and the viscosity of the preparation is 320mPa.s.

Embodiment 3

[0103] Example 3 Preparation of MMB4 DMS nanosuspension

[0104] Weigh 27kg of cottonseed oil, slowly add 3kg of MMB4 DMS, stir and mix; ultrasonically homogenize for 10min, ultrasonic frequency 15000rpm; pour into a wet mill for grinding, temperature 30°C, initial speed 6m / s, increase the speed every 5 minutes 1m / s, until 11m / s, grind for 4h, that is.

[0105] The particle size of the prepared midazolam nanocrystals was 253.2nm, the polydispersity index (PDI) was 0.327, and the viscosity of the preparation was 345mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com