A kind of biomass hydrothermal carbon carrier catalyst and its preparation method and application

A hydrothermal carbon and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of complex process, high cost, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

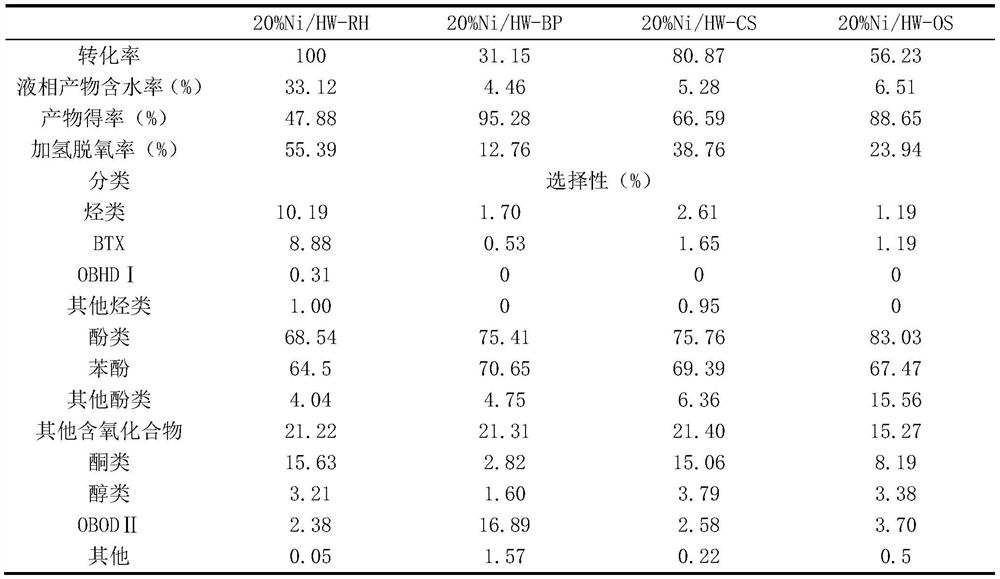

[0057] Embodiment 1 different biomass raw materials

[0058] 1. Take 30g of rice husk, bamboo powder, corn stalk powder and eucalyptus sawdust powder raw materials crushed to 80 mesh, mix them with 300ml of deionized water respectively, and add them to a 500ml stainless steel reaction kettle, stir evenly, seal it, and put it into the rotor Let it stir, and place it in a heating mantle, heat up to 240°C at a rate of 2°C / min, react for 30 minutes, cool at room temperature, take out the hydrothermal liquid mixture and perform suction filtration, wash with ethanol and suction filtration once, and then wash with water And suction filtration once, and finally repeat the operation of ethanol cleaning suction filtration-water cleaning suction filtration twice. The dried hydrothermal carbon was dried in an oven at 80° C. for 12 hours to obtain hydrothermal carbon.

[0059] 2. Put the hydrothermal carbon in step 1 in a tube furnace under a nitrogen flow rate of 150ml / min, and pyrolyze ...

Embodiment 2

[0066] Embodiment 2 Acidification, pyrolysis treatment

[0067] 1. Add 30 g of raw rice husk to 300 ml of nitric acid solution with a mass concentration of 45% for acidification and stirring for 5 hours, filter, wash until neutral and dry to obtain the acidified rice husk raw material.

[0068] 2. Mix 30g of rice husk raw material with 300ml of deionized water, add it to a 500ml stainless steel reaction kettle, seal it after stirring evenly, put it into a rotor to stir it, and place it in a heating mantle to raise the temperature at a rate of 2°C / min After reaching 240°C, react for 30 minutes, cool at room temperature, take out the hydrothermal liquid mixture and filter with suction, use ethanol and deionized water to exchange, wash and filter 3 times, then use ethanol to wash and filter once, then wash with water and filter once, Finally, the operation of ethanol cleaning and suction filtration-water cleaning and suction filtration was repeated twice; the dried hydrothermal c...

Embodiment 3

[0077] Embodiment 3pH variable experiment

[0078] 1. Use low-concentration NaOH or HCl aqueous solution to obtain five aqueous solutions with pH=2, 4, 7, 10, and 12 by titration.

[0079] 2. Add 300ml of the five aqueous solutions of step 1 to the high-pressure hydrothermal reaction kettle, and then add 30g of rice husk raw materials crushed to 80 meshes, start from room temperature and heat up to 240°C at a heating rate of 1.5°C / min, and then heat up to 240°C at 240°C Reaction 0.5h. Let cool at room temperature. The hydrothermal mixture obtained after cooling was removed and filtered off with suction. Wash with ethanol and filter once, then wash with water and filter once, and finally repeat the operation of washing with ethanol and filtering with water-washing and filtering twice, and drying at 80°C for 24 hours to obtain five kinds of hydrothermal carbons.

[0080] 3. All the five kinds of hydrothermal carbons in step 2 were placed in a tube furnace, and after pyrolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com