Forming process of fastener

A forming process and fastener technology, applied in the field of forming process of fasteners, can solve problems such as increased stress and strain, low yield, severe deformation, etc., achieve stress and strain reduction, small processing damage, and reduce wire deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

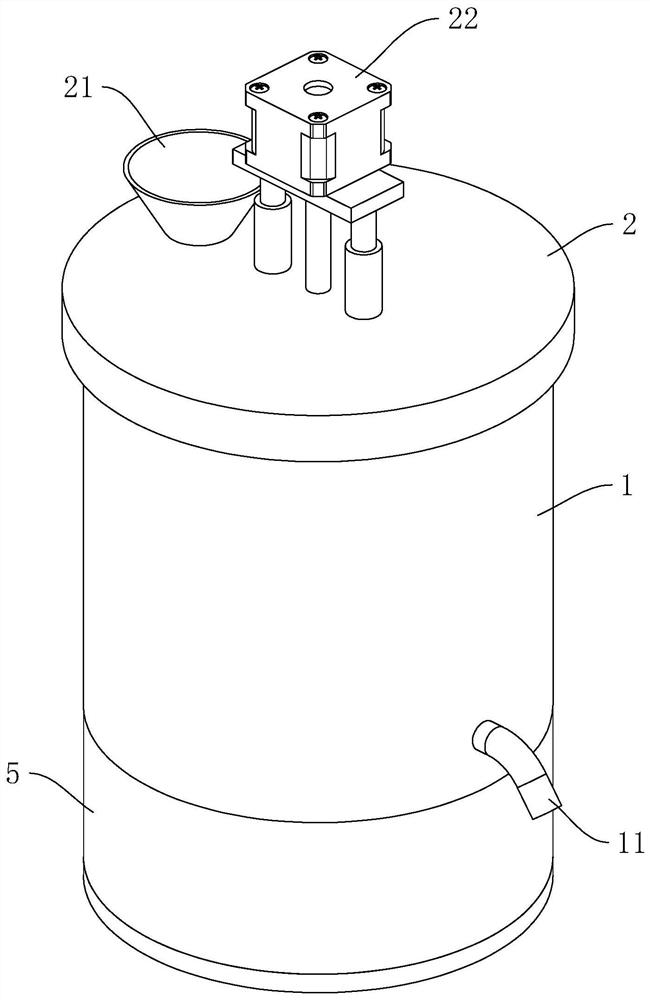

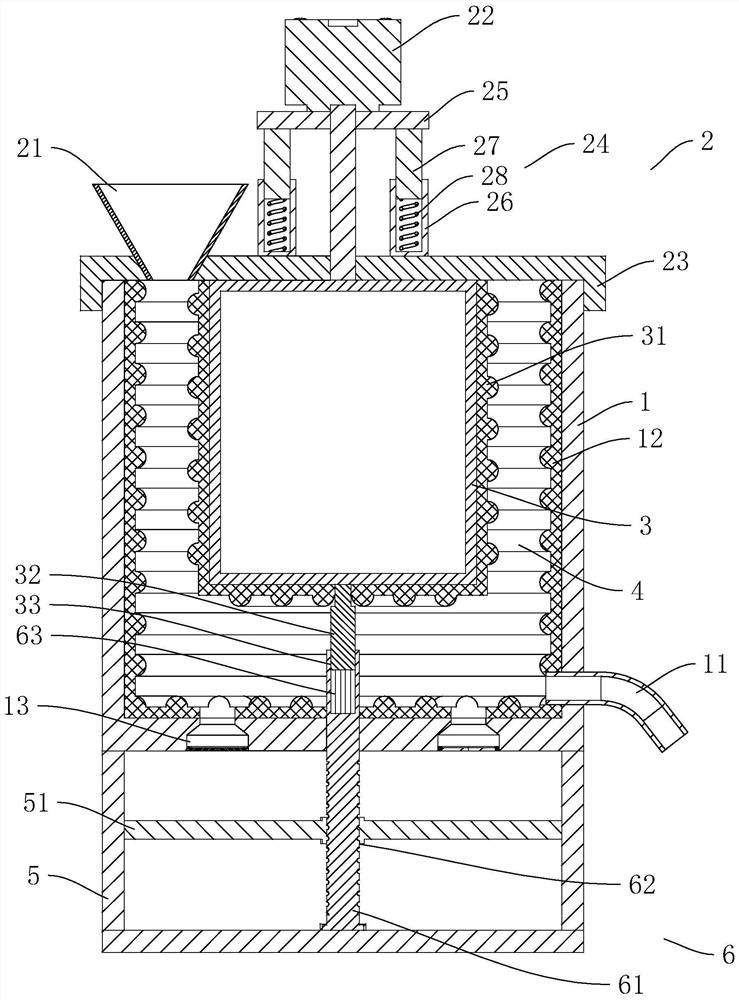

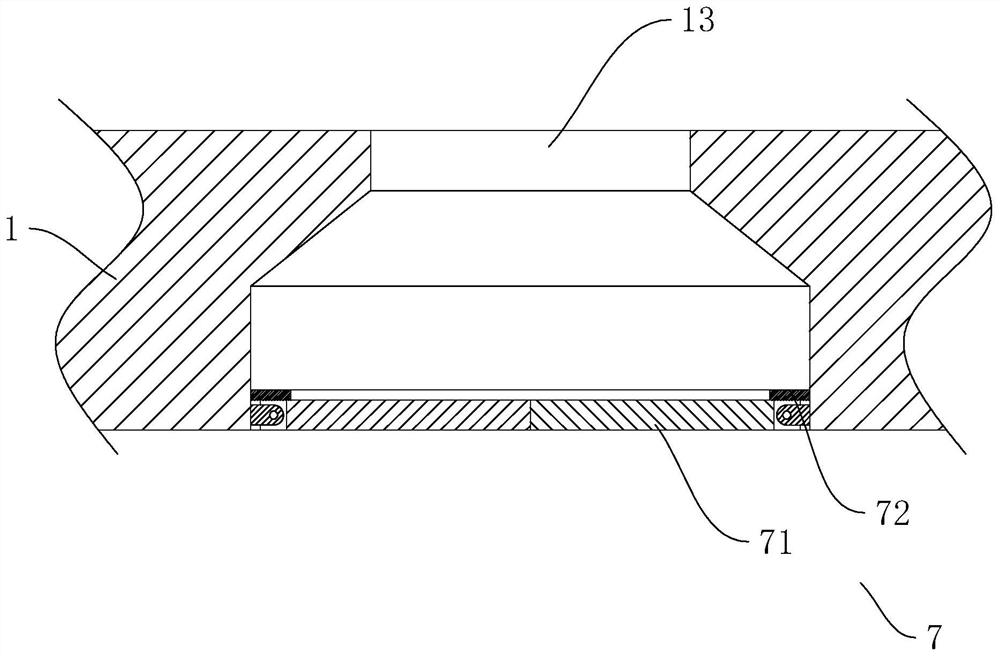

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0042] A forming process for fasteners, comprising the steps of:

[0043]S1, material selection, according to the processing size of the fastener product, select the appropriate wire as the raw material for the fastener forming;

[0044] S2, heat treatment, after continuously heating the heating furnace to 900-920°C, place the raw materials in the heating furnace and keep warm for 30-40min; then keep the temperature constant, continue to feed methanol and propane into the heating furnace, keep warm for 390-410min , do carburizing treatment; then take the raw materials out of the heating furnace, oil-cool the raw materials, cool the heating furnace to 180-200°C, put the raw materials into the heating furnace, keep warm for 170-190min, and do tempering treatment;

[0045] S3, pickling, first use the sulfuric acid solution with a concentration of 18% to pickle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com