Preparation method of reactive dye blue

A technology of reactive dyes and compounds, applied in the field of dyes, can solve the problems of color flower and vat difference, high energy consumption, lengthy process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

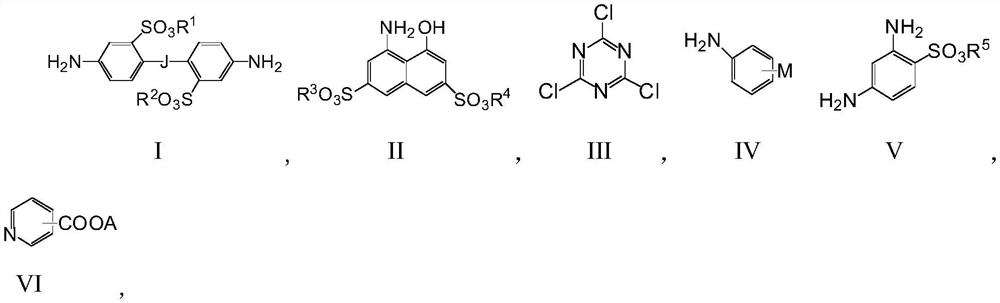

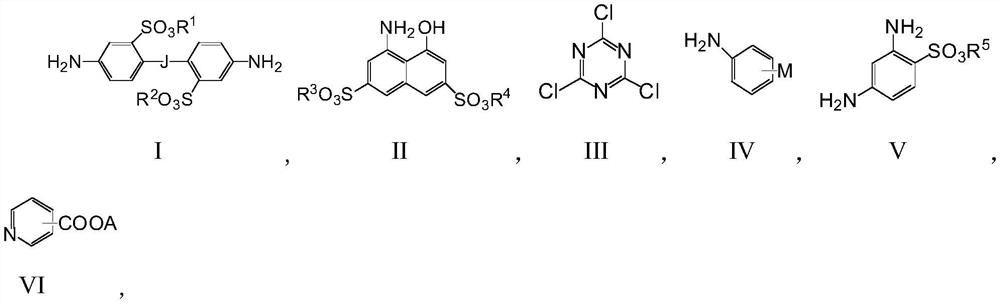

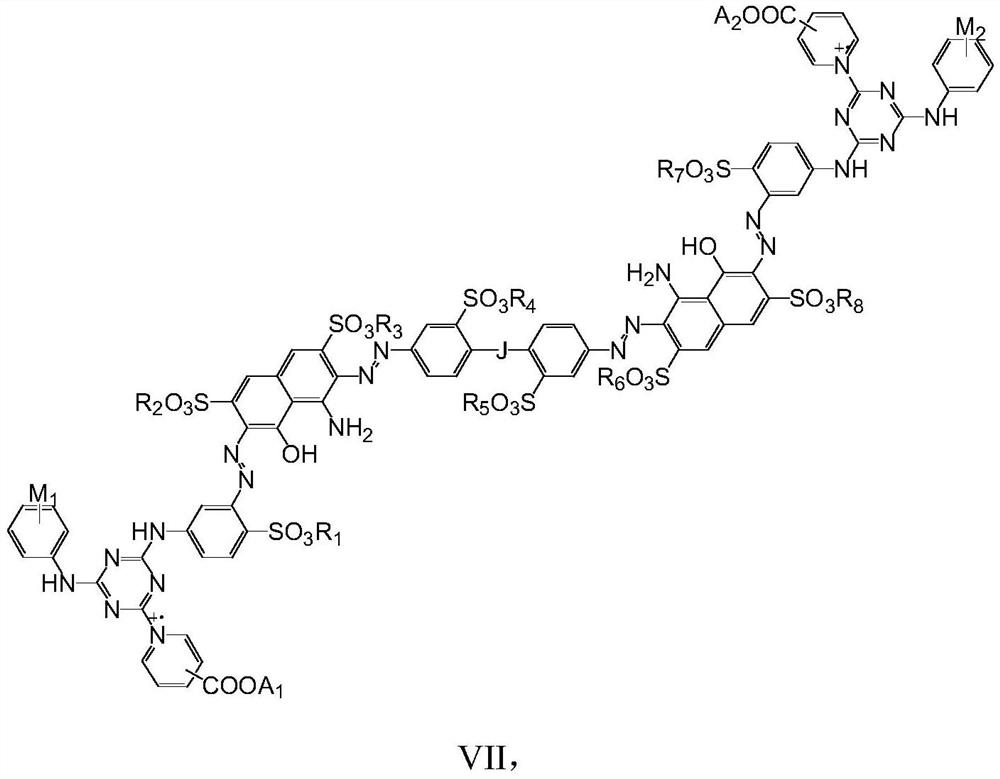

Method used

Image

Examples

Embodiment 1

[0068] The reactive dye blue provided by the present embodiment is prepared by the following method:

[0069] (1) will Add it into water and crushed ice and stir, keep the temperature at 0-5°C, add hydrochloric acid and then add sodium nitrite to react for 1.5 hours to obtain the first mixed solution, wherein, The molar ratio of HCl and sodium nitrite is 1:1.0:1.01, and the hydrochloric acid selects the hydrochloric acid of concentration 30% for use;

[0070] (2) Add to the first mixed solution obtained in step (1) Add sodium bicarbonate to adjust the pH value to 2.5-3.0, react at 10-15°C for 5.5 hours to obtain the second mixed solution, wherein, and The feeding molar ratio is 1:2.02;

[0071] (3) Will Add to crushed ice and water and stir, then add Then add sodium bicarbonate to adjust the pH value to 3.0-3.5, react at 5-10° C. for 3.5 hours to obtain the third mixed solution, wherein, and The feeding molar ratio is 1:0.99;

[0072] (4) will Add to the th...

Embodiment 2

[0081] The reactive dye blue provided by the present embodiment is prepared by the following method:

[0082] (1) will Add it into water and crushed ice and stir, keep the temperature at 0-5°C, add hydrochloric acid and then add sodium nitrite to react for 1.5 hours to obtain the first mixed solution, wherein, The mol ratio of hydrochloric acid and sodium nitrite is 1:1.0:1.01, and hydrochloric acid selects the hydrochloric acid of concentration 30% for use;

[0083] (2) Add to the first mixed solution obtained in step (1) Add sodium bicarbonate to adjust the pH value to 2.5-3.0, react at 10-15°C for 6 hours to obtain the second mixed solution, wherein, and The feeding molar ratio is 1:2.02;

[0084] (3) Will Add to crushed ice and water and stir, then add Then add sodium bicarbonate to adjust the pH value to 3.0-3.5, react at 5-10° C. for 3 hours to obtain the third mixed solution, wherein, and The feeding molar ratio is 1:0.99;

[0085] (4) will Add to the...

Embodiment 3

[0094] The reactive dye blue provided by the present embodiment is prepared by the following method:

[0095] (1) will Add it into water and crushed ice and stir, keep the temperature at 0-5°C, add hydrochloric acid and then add sodium nitrite to react for 1.5 hours to obtain the first mixed solution, wherein, The molar ratio of HCl and sodium nitrite is 1:1.0:1.01, and the hydrochloric acid selects the hydrochloric acid of concentration 30% for use;

[0096] (2) Add to the first mixed solution obtained in step (1) Add sodium bicarbonate to adjust the pH value to 2.5-3.0, react at 10-15°C for 5 hours to obtain the second mixed solution, wherein, and The feeding molar ratio is 1:2.02;

[0097] (3) Will Add to crushed ice and water and stir, then add Then add sodium bicarbonate to adjust the pH value to 2.5-3.0, react at 5-10° C. for 4 hours to obtain the third mixed solution, wherein, and The feeding molar ratio is 1:1.01;

[0098] (4) will Add to the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com