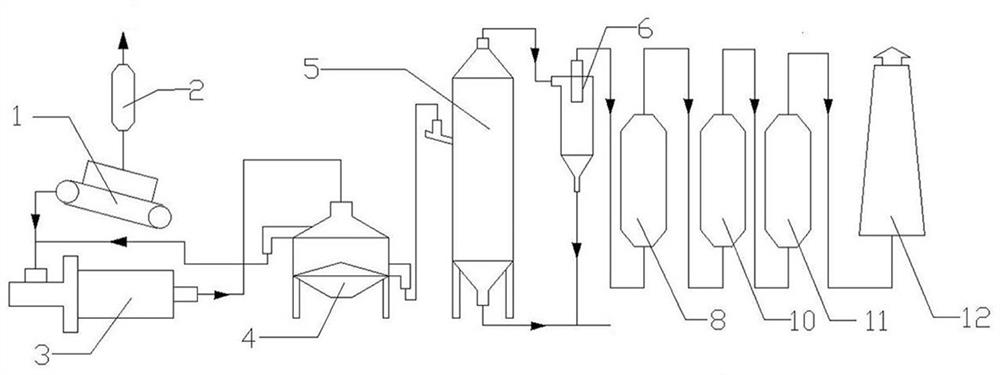

Byproduct sodium chloride salt recovery device, special incinerator thereof and byproduct sodium chloride salt recovery method

A by-product sodium chloride and incinerator technology, which is applied in combustion methods, incinerators, lighting and heating equipment, etc., can solve the high cost of by-product sodium chloride salt treatment, incomplete removal of organic matter, incomplete incineration of organic matter, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

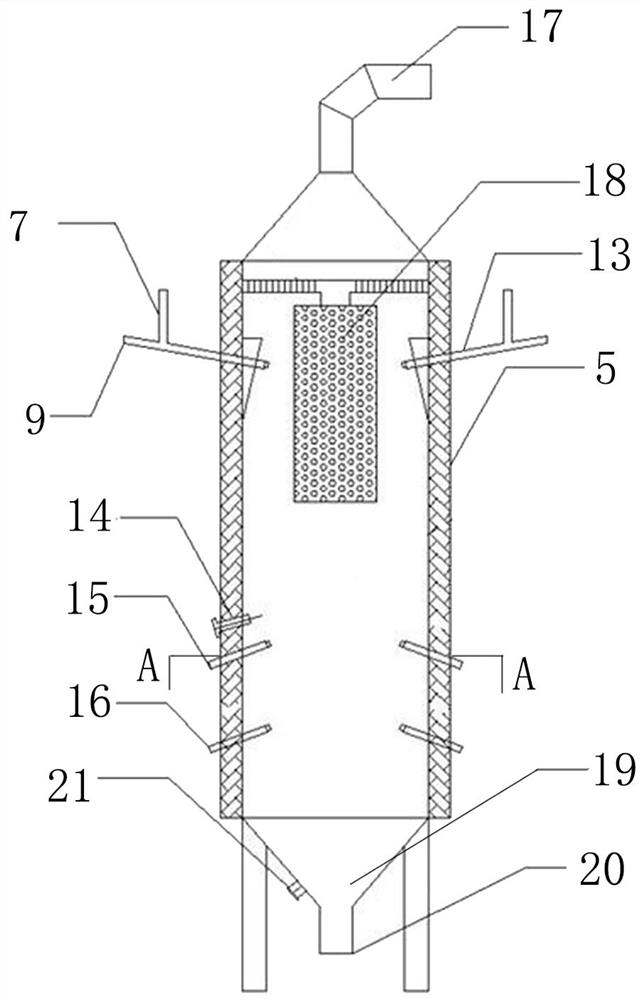

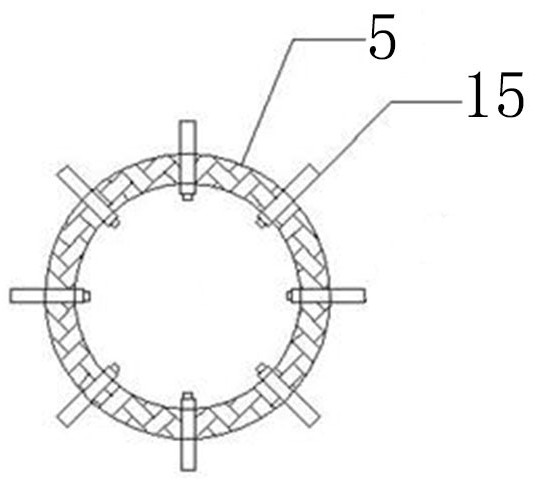

[0084]Using the above by-product sodium chloride salt recovery equipment, select the best parameters, namely, the ratio of the outer diameter of the salt powder disperser 18 to the inner diameter of the incinerator body 5 is set to 1:1.7, and the height of the salt powder disperser 13 It is set to 1 / 3 of the height of the inner cavity of the main body of the incinerator, and the wall thickness of the salt powder disperser 13 is set to 3.5 cm. The dispersion holes 22 are set as circular holes with a diameter of 3 cm, the distance between the edges of adjacent dispersion holes 22 is set to 1.5 cm, and the pits 23 set on the surface of the cylinder between the dispersion holes 22 are circular holes with an angle of 15°. pit. Using the best-parameter by-product sodium chloride salt recovery equipment, three batches of experiments were carried out through the above method, and salt powder and salt water with a concentration of 300g / L were prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com