Detection test strip based on quantum dot labeling as well as preparation method and application thereof

A technology of quantum dots and test strips is applied in the field of Salmonella detection test strips and their preparation, which can solve the problems of small quantity and efficient detection, and achieve the effects of low cost, simple operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

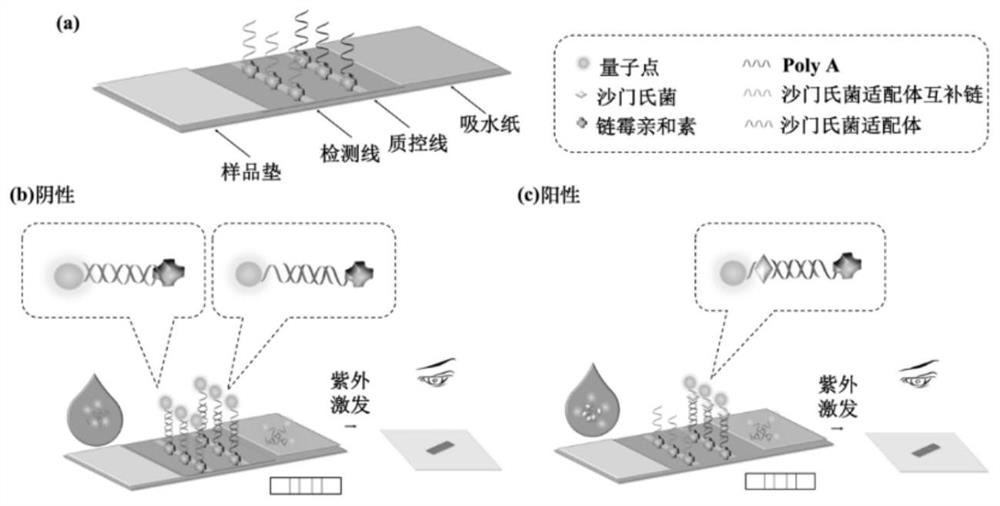

[0034] Preparation of test strips:

[0035] S1: First stick the NC film on the back plate, then stick the sample pad and absorbent paper on the upper and lower sides of the NC film respectively, covering the edge of the NC film by about 2mm;

[0036]S2: Take 50 μL 0.125 mg / mL streptavidin (SA) solution, add biotin to modify the complementary chain of aptamer to obtain solution 1; take 50 μL 0.125 mg / mL streptavidin (SA) solution, add biotin Poly A was modified to obtain solution 2, and solution 1 and solution 2 were placed in a shaker at 37°C and 180 RPM to incubate overnight, and the incubated conjugate solution 1 and conjugate solution 2 were respectively mixed at 1.0 The μL / cm spraying amount is sprayed on the T line and C line of the NC film to obtain the sprayed test paper;

[0037] S3: Dry the test paper sprayed in step S2 at 37°C for 2 hours to fix the T-line and C-line on the NC film, and finally use a strip cutter to cut the test paper into 4mm wide test strips and p...

Embodiment 2

[0041] Preparation of test strips:

[0042] S1: First stick the NC film on the back plate, then stick the sample pad and absorbent paper on the upper and lower sides of the NC film respectively, covering the edge of the NC film by about 3mm;

[0043] S2: Take 50 μL 0.125 mg / mL streptavidin (SA) solution, add biotin to modify the complementary chain of aptamer to obtain solution 1; take 50 μL 0.125 mg / mL streptavidin (SA) solution, add biotin Poly A was modified to obtain solution 2, and solution 1 and solution 2 were placed in a shaker at 37°C and 180 RPM to incubate overnight, and the incubated conjugate solution 1 and conjugate solution 2 were respectively mixed at 1.0 The μL / cm spraying amount is sprayed on the T line and C line of the NC film to obtain the sprayed test paper;

[0044] S3: Dry the test paper sprayed in step S2 at 37°C for 2 hours to fix the T-line and C-line on the NC film, and finally use a strip cutter to cut the test paper into 4mm wide test strips and ...

Embodiment 3

[0048] Preparation of test strips:

[0049] S1: First stick the NC film on the back plate, then stick the sample pad and absorbent paper on the upper and lower sides of the NC film respectively, covering the edge of the NC film by about 4mm;

[0050] S2: Take 50 μL 0.125 mg / mL streptavidin (SA) solution, add biotin to modify the complementary chain of aptamer to obtain solution 1; take 50 μL 0.125 mg / mL streptavidin (SA) solution, add biotin Poly A was modified to obtain solution 2, and solution 1 and solution 2 were placed in a shaker at 37°C and 180 RPM to incubate overnight, and the incubated conjugate solution 1 and conjugate solution 2 were respectively mixed at 1.0 The μL / cm spraying amount is sprayed on the T line and C line of the NC film to obtain the sprayed test paper;

[0051] S3: Dry the test paper sprayed in step S2 at 37°C for 2 hours to fix the T-line and C-line on the NC film, and finally use a strip cutter to cut the test paper into 4mm wide test strips and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com