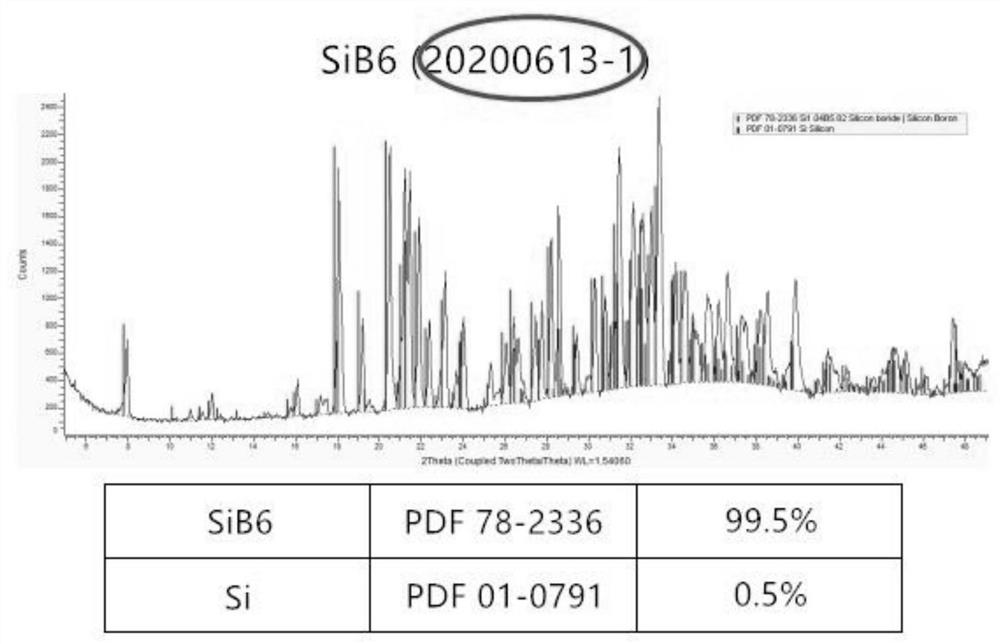

A low-cost high-purity silicon hexaboride production process

A pure silicon hexaboride and production process technology, applied in the direction of boron/boride, etc., can solve the problems of high production cost, high fineness requirements of raw silicon powder and boron powder, etc., to achieve short production cycle, guaranteed reduction effect, The effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

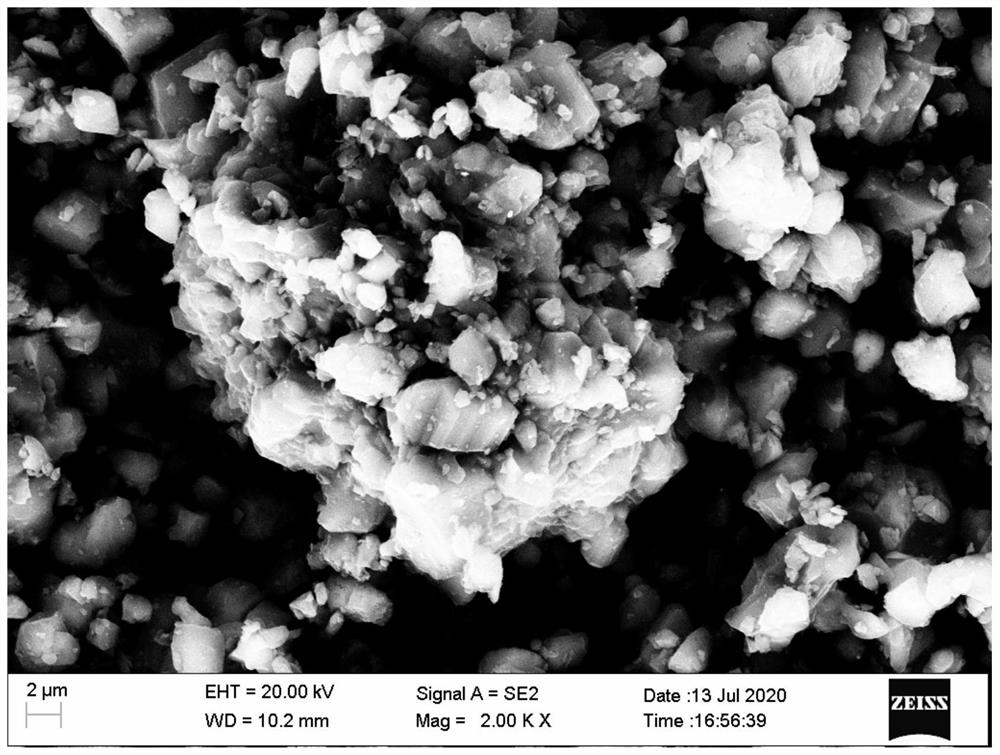

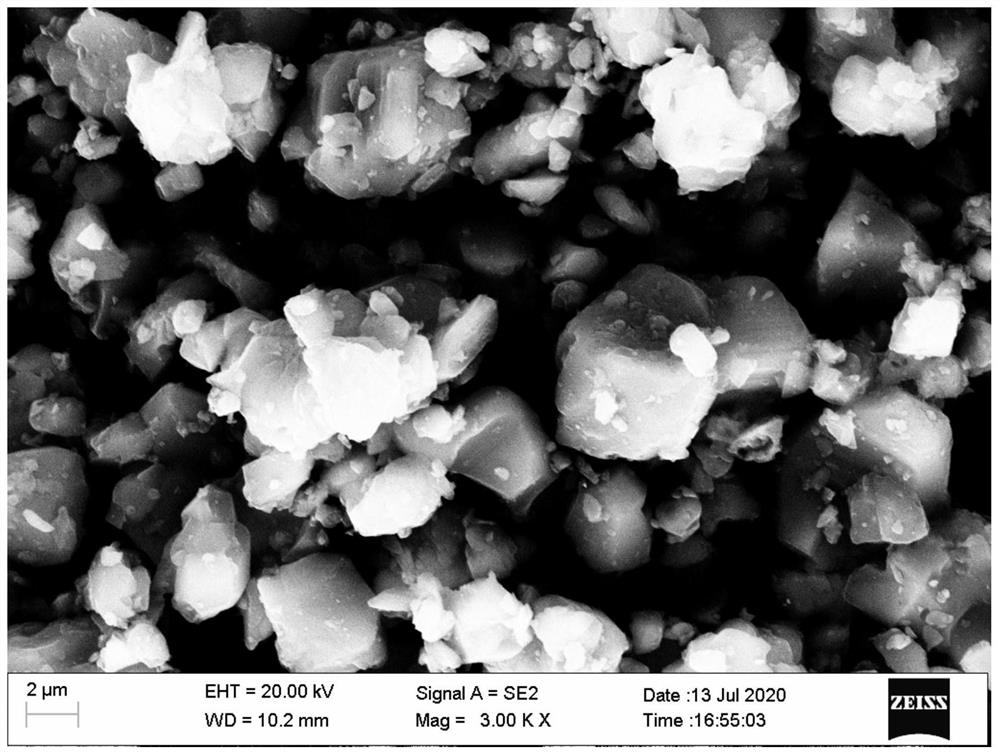

Examples

Embodiment

[0022] (1) Select raw materials: the purity of diboron trioxide is 99.5%, and the fineness is 325 meshes; the purity of potassium borohydride is 99.9%, and the fineness is 400 meshes;

[0023] Ball milling and mechanical alloying: put 19.659 kg of diboron trioxide and 30.341 kg of potassium borohydride (molar ratio of 1:2) into an interstellar ball mill, reaction equation B 2 0 3 +2KBH 4 =4B+2KOH+H 2 O+2H 2 , rushed into the argon protection, the ball-milling mixing time is guaranteed to be 12 hours, and the mechanical alloying is achieved, and the mixed powder is obtained;

[0024] (2) Press the mixed powder according to 500 grams per portion with a 315-ton hydraulic press, and the pressing pressure is not less than 25 MPa, so as to ensure that the powder is densely combined and fully replaced and reacted to obtain a pressed block;

[0025] (3) The pressed block material is loaded into a graphite crucible according to 10 kilograms of the charging amount of each furnace, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com