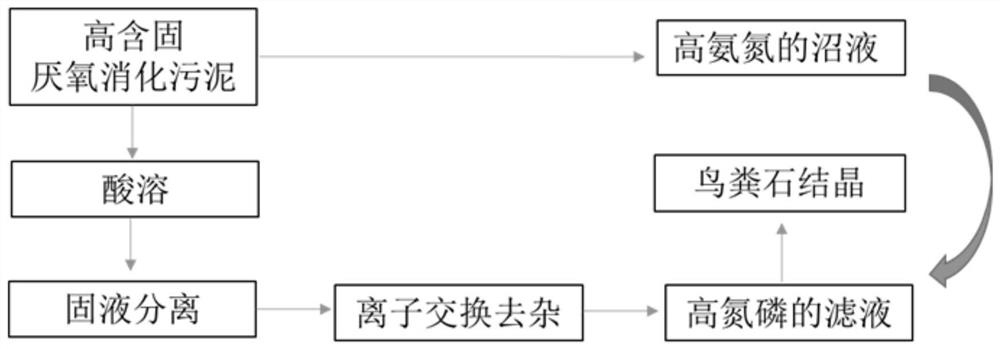

Synchronous recovery treatment method for nitrogen and phosphorus in high-solid-content anaerobic digestion sludge

An anaerobic digestion and recovery treatment technology, which is applied in the field of sludge recycling, can solve the problems of high ammonia nitrogen concentration, low phosphorus release efficiency, and the inability to effectively simultaneously realize the recovery of nitrogen and phosphorus in anaerobic digestion sludge, and achieve separation efficiency High, improved release efficiency, high release rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take high-solid anaerobic digested sludge with a solid content of 10%, a total phosphorus content of 28mg / g TS, and an ammonia nitrogen concentration of 2000mg / L in the biogas slurry. Add dilute sulfuric acid to the sludge, adjust pH=2, react for 0.5h, the release rate of phosphate in the sludge reaches 90%, carry out plate and frame pressure filtration on the acid-soluble product, the concentration of phosphate in the filter liquid is 2520mg / L. Take 100 ml of press filtrate, add 50 g of ion exchange resin, stir at 300 rpm for 30 min, and finally remove 80% of aluminum and iron in the filtrate. Finally, MgCl was added to the filtrate 2 ·6H 2 0, make the Mg:P molar ratio in the filtrate be 1.2~1.4, utilize plant ash to adjust pH to 9, stir 20min with 200rpm, stand and settle for 30min, the recovery rate of phosphate recorded in the supernatant reaches 90%, the removal rate of ammonia nitrogen to 57%.

Embodiment 2

[0041] Take high-solid anaerobic digested sludge with a solid content of 18%, a total phosphorus content of 20mg / g TS, and an ammonia nitrogen concentration of 2500mg / L in the biogas slurry. Adding concentration to the sludge is 2M dilute sulfuric acid, adjusting pH=2, reacting for 1h, the release rate of phosphate in the sludge reaches 80%, and performing plate and frame pressure filtration on the acid-soluble product, the concentration of phosphate in the filter liquid is 2880mg / L. Take 100 ml of press filtrate, add 90 g of ion exchange resin, stir at 300 rpm for 30 min, and finally remove 85% of aluminum and iron in the filtrate. Finally, MgCl was added to the filtrate 2 ·6H 2 0, make the Mg:P mol ratio in the filtrate be 1.2, utilize plant ash to adjust pH to 9, stir 20min with 200rpm, leave standstill precipitation 30min, supernatant liquid records the rate of recovery of phosphate to reach 92%, and the removal rate of ammonia nitrogen reaches 63%. %.

Embodiment 3

[0043] Take high-solid anaerobic digested sludge with a solid content of 15%, a total phosphorus content of 25mg / g TS, and an ammonia nitrogen concentration of 2300mg / L in the biogas slurry. Add concentration of 2M dilute sulfuric acid to the sludge, adjust pH=2, react for 1h, the release rate of phosphate in the sludge reaches 85%, carry out plate and frame pressure filtration on the acid-soluble product, and the concentration of phosphate in the filter liquid is 3000mg / L. Take 100 ml of press filtrate, add 75 g of ion exchange resin, stir at 300 rpm for 30 min, and finally 86% of aluminum and iron in the filtrate are removed. Finally, MgCl was added to the filtrate 2 ·6H 2 0, make the Mg:P mol ratio in the filtrate be 1.4, utilize plant ash to adjust pH to 9, stir 20min with 200rpm, leave standstill to precipitate 30min, the rate of recovery of phosphate recorded in the supernatant reaches 95%, and the removal rate of ammonia nitrogen reaches 65%. %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com