Condensation method for styrene thermoplastic elastomer solution

A thermoplastic elastomer and styrene-based technology, which is applied in the field of coagulation of styrene-based thermoplastic elastomer solutions, to achieve the effect of ensuring coagulation effect, reducing environmental protection requirements, and reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

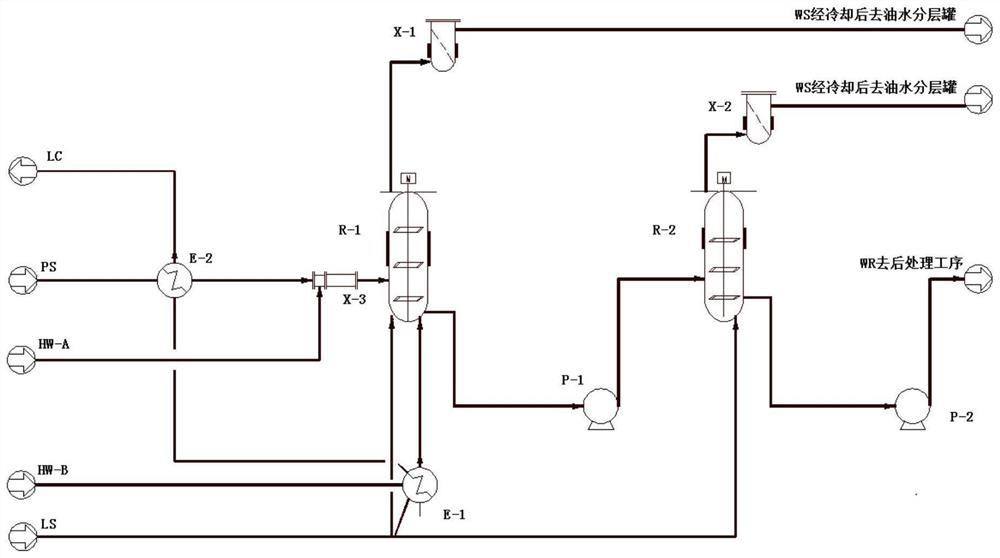

[0058] The coagulation process of this embodiment adopts the equal pressure temperature difference type, and its process flow chart is as follows figure 1 As shown, the styrene thermoplastic elastomer solution PS (specifically styrene-butadiene-styrene block copolymer rubber solution, the solvent is cyclohexane, hereinafter referred to as glue) is sent to the glue heater E After the second heat exchange with the first steam condensed water in -2, it is sent to the water glue mixer X-3 to mix with the post-treatment circulating hot water A sent in to obtain a heterogeneous mixture, and the obtained heterogeneous The phase mixture is sent to the first condensation tank R-1, and the gas phase WS at the top of the tank passes through the stripping gas filter X-1 of the first condensation tank and the condensing cooler, and then enters the oil-water stratification tank for stratification; in addition, the post-treatment cycle The hot water B is sent to the circulating hot water hea...

Embodiment 2

[0062] The post-treatment circulating hot water B / A is 0.15, and other process conditions are the same as in Example 1. The experimental results are shown in Table 1.

Embodiment 3

[0064] The post-treatment circulating hot water B / A is 0.3, and other process conditions are the same as in Example 1. The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com