Crystal growth process control method based on solution concentration online estimation

A technology of crystal growth and solution concentration, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problem of inability to measure the concentration of the growth solution online, and achieve the effect of ensuring quality, stable growth rate, and fast growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation of the patent of the present invention will be further described below in conjunction with the accompanying drawings.

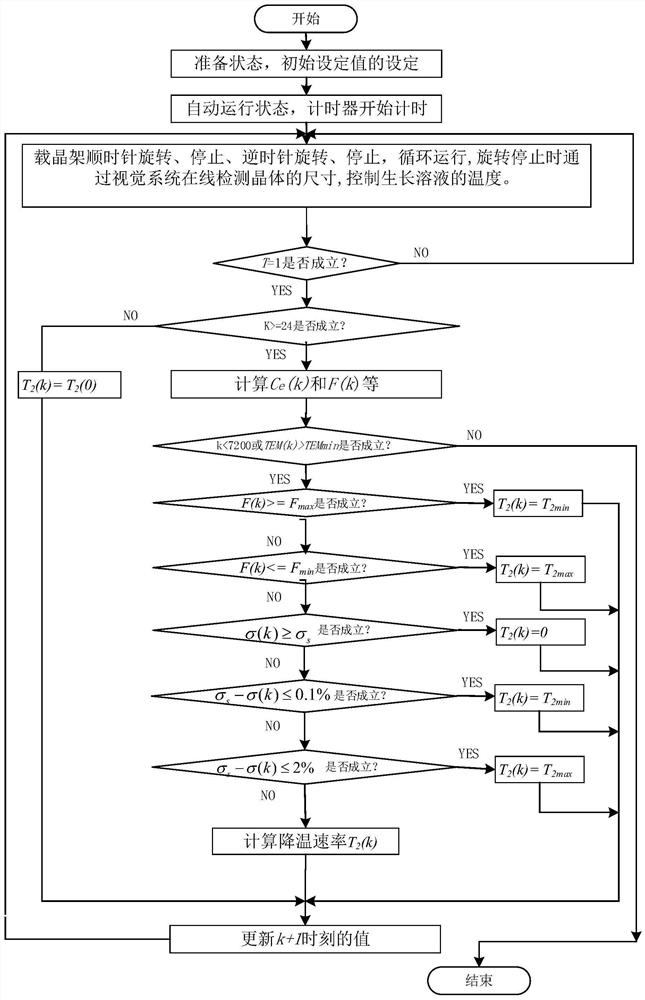

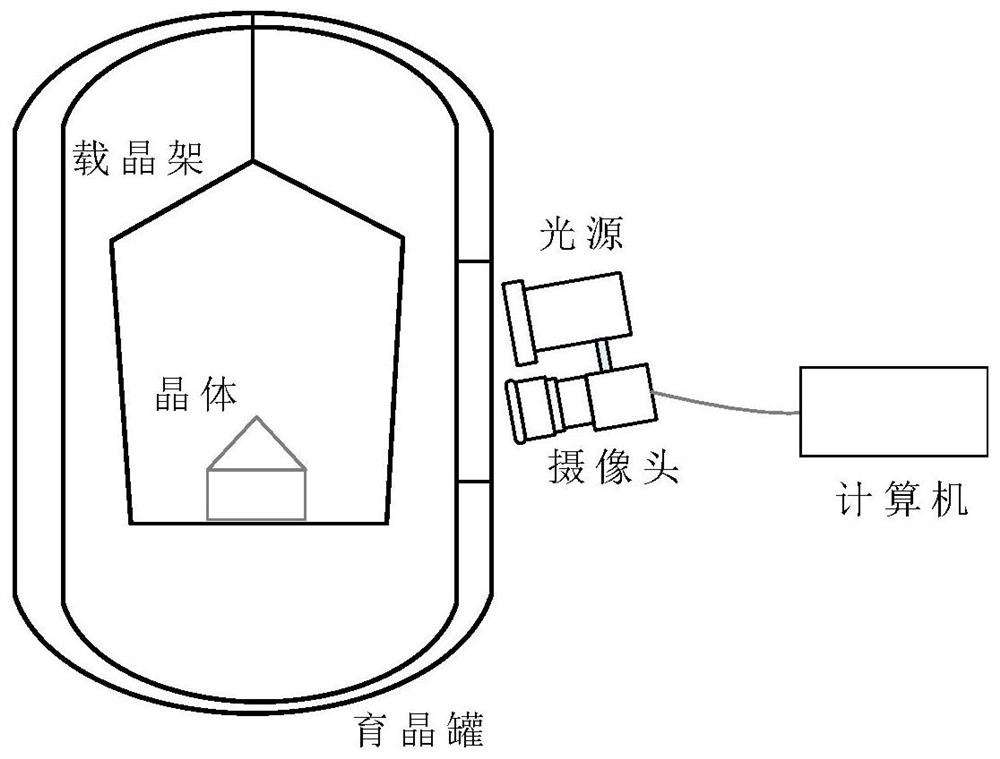

[0035] An application of an on-line control method for the supersaturation of a growth solution in a crystal growth process, comprising the following implementation process:

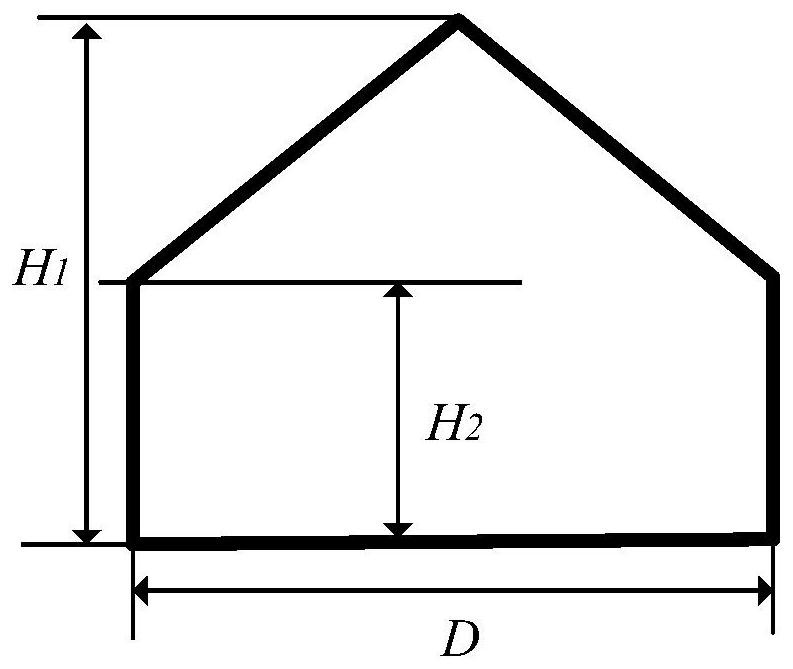

[0036] (1) Potassium dihydrogen phosphate growth solution is loaded into the crystal growth tank, and after the crystal nucleus is placed on the crystal carrier, the system enters the operation preparation state, and the setting of the initial setting value is carried out on the touch screen: T 1 (0) = 60.00°C, T 1min =25°C; T 2 (0)=0.02°C / hour, T 2max =0.05°C / hour, T 2min =0.01°C / hour; M(0)=1000,000g, C(0)=0.300g crystal / g solution, F(0)=2.00%, F max = 4.00%, F min = 1.00%; H 1 (0)=5.0cm, H 2 (0)=2.5cm, D(0)=5.0cm; ρ s =2.34g / cm 3 , σ s =6.0%; k=0, T=0.

[0037] (2) The system enters the automatic operation state, and the timer T starts tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com