Anti-leakage construction process for installation of external flush type external window

A construction technique and anti-leakage technology, which is applied in the direction of window/door frame, base frame, frame fixing, etc., can solve problems such as broken and empty plastering layer, difficult maintenance, bubble damage to the decoration surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] The anti-leakage construction process for installing the flush outer window provided in this embodiment includes the following steps:

[0100] (1) Construction preparation

[0101] Before construction, mechanical equipment and materials enter the site; relevant construction personnel arrive at their posts; technicians and safety officers organize technical and safety disclosures, so that construction operators can clarify design and construction requirements, and enhance safety awareness; and technical personnel arrange special personnel to be responsible Record and quality inspection work. Determine the thickness of the window frame to be installed in the later stage, and determine the construction scope of the outer slope water table and inner groove plastering.

[0102] (2) Grassroots cleaning and treatment

[0103] Chisel out the raised part of the concrete surface. For the honeycomb, pitted surface, leaking reinforcement, loose and other parts, the surface laita...

Embodiment 2

[0171] Embodiment 2 application example

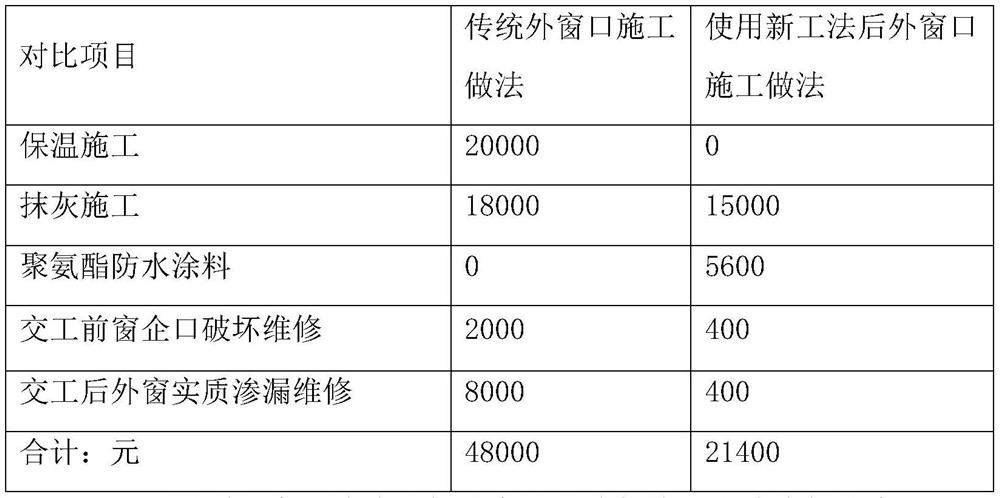

[0172] 1 Building 8#-26# of Linmeidi Project, underground garage and supporting projects, this project is located in Chengyang District, Qingdao City. The total construction area is 100,000 square meters. The ground floor area is 80,000 square meters. The underground construction area is 20,000 square meters, with one floor underground and 9-11 floors above ground. The start date of the project is November 29, 2014, and the completion date is August 19, 2016; the project has a total of 1,640 external windows. Although this project is delivered in rough form, in order to pursue the purpose of quality service, the owner strives to prevent leakage after the interior decoration. The method of exterior windows is completely installed according to this construction method. After maintenance and long-term observation, no leakage has been found on the exterior windows and other quality problems. By adopting this construction method, this pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com