Tunnel structure defect repairing system and construction method

A tunnel structure and disease technology, applied in road repair, tunnel, tunnel lining, etc., can solve the problems of unproven surrounding rock water system and base, heavy workload and construction difficulty, inclined deformation of cable trench, etc., and achieve good economical and implementability, save construction procedures, and reduce the effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

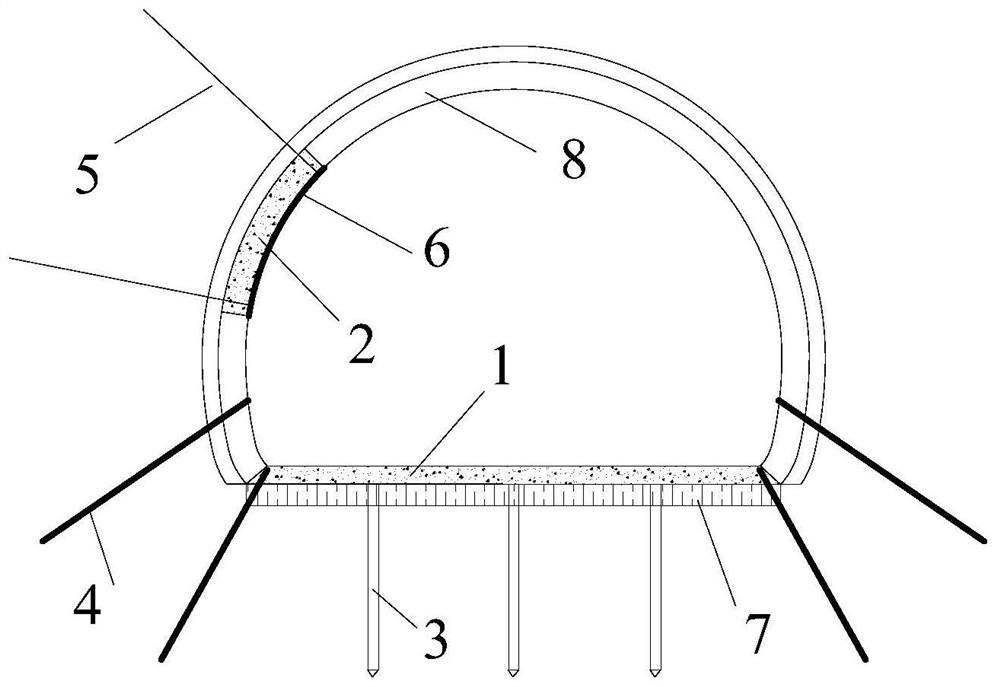

Embodiment 1

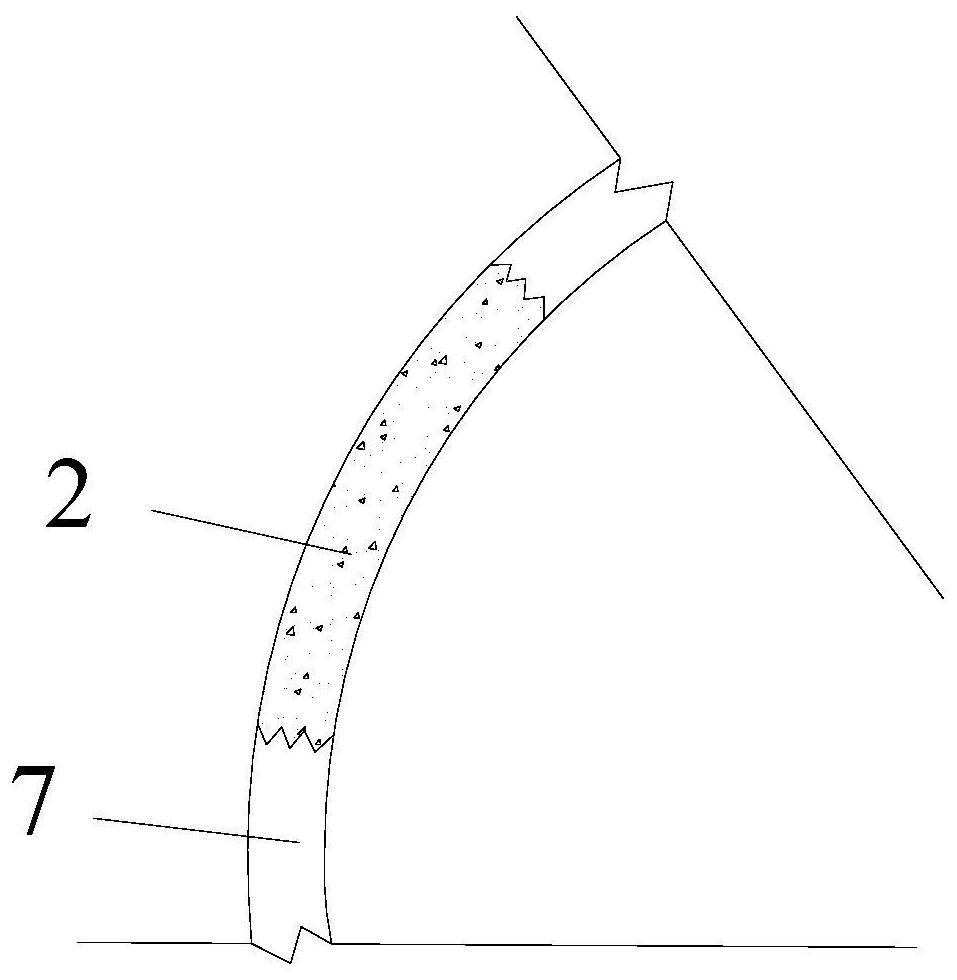

[0026] The example is a certain expressway tunnel, which is a separate tunnel, with a single tunnel and two lanes, a net width of 10.25m, and a height limit of 5.0m. The second lining of the tunnel is plain concrete of 40cm without inverted arches. Shortly after the operation of the tunnel, there were local lining cracks and pieces, pavement uplift and cracks, and cable trench slopes and other diseases. There was a certain degree of intrusion in the severely damaged parts of the arch waist, and the maximum intrusion reached 8cm. After testing, there is a weak mudstone layer in the basement, which softens when exposed to water. At the same time, the thickness of the lining at the location where the disease is serious does not meet the design requirements, and the actual thickness is 20-35cm.

[0027] The parameters of the UHPC material used in the disease treatment process are as follows: compressive strength f cu =150MPa, tensile strength f tu =7.5MPa, bending strength f b =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com