Preparation method of sulfur-doped ReSe2/MXene composite material

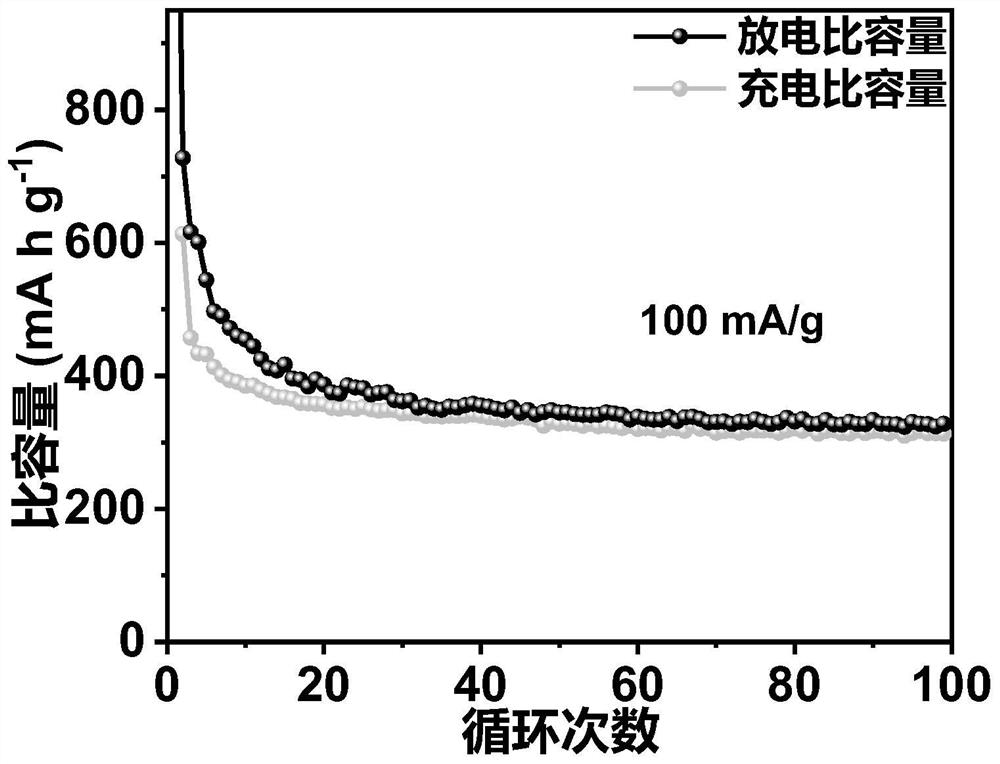

A composite material and sulfur-doped technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of limited development, easy agglomeration, poor conductivity, etc., to improve potassium storage performance, increase specific surface area, The effect of increasing the layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A sulfur-doped ReSe 2 The preparation method of / MXene composite material, comprises the following steps:

[0041] (1) Add 0.1mmol of ReSe 2 Nanoparticles, 10ml of N,N-dimethylformamide (DMF) and 5ml of ultrapure water were fully stirred and mixed to obtain a suspension;

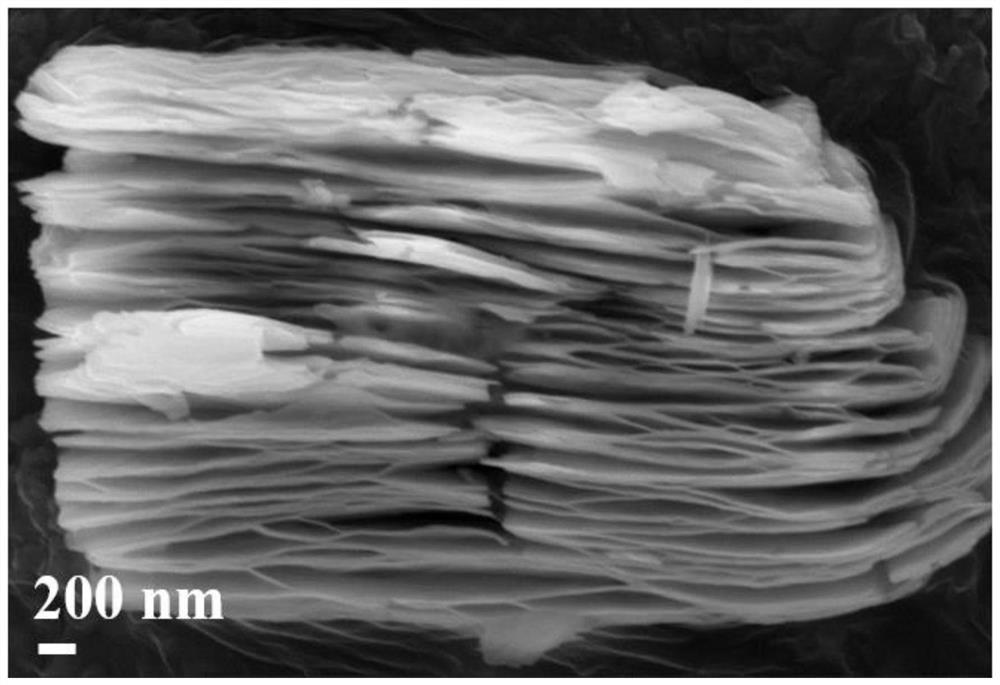

[0042] (2) 0.1mmol of MXene (Ti 3 C 2 T x ) nanosheets, suspension, 0.06 mmol of sulfur powder and 15 ml of ultrapure water were mixed, treated in an ultrasonic cleaner with an ultrasonic frequency of 50 W for 0.5 h at 25 ° C, and then magnetically stirred for 4 h to obtain a mixed solution;

[0043] (3) Transfer the stirred mixed solution into a reaction kettle with a capacity of 60ml, and heat it to 150°C in a microwave heating box, react for 10h, and naturally cool to room temperature; Centrifuge for 5 minutes under the same conditions, remove the filter residue of the supernatant, wash with deionized water and absolute ethanol three times respectively, and then dry in a vacuum drying oven to o...

Embodiment 2

[0048] A sulfur-doped ReSe 2 The preparation method of / MXene composite material, comprises the following steps:

[0049] (1) Add 0.1mmol of ReSe 2 Nanoparticles, 15ml of N,N-dimethylformamide (DMF) and 10ml of ultrapure water were fully stirred and mixed to obtain a suspension;

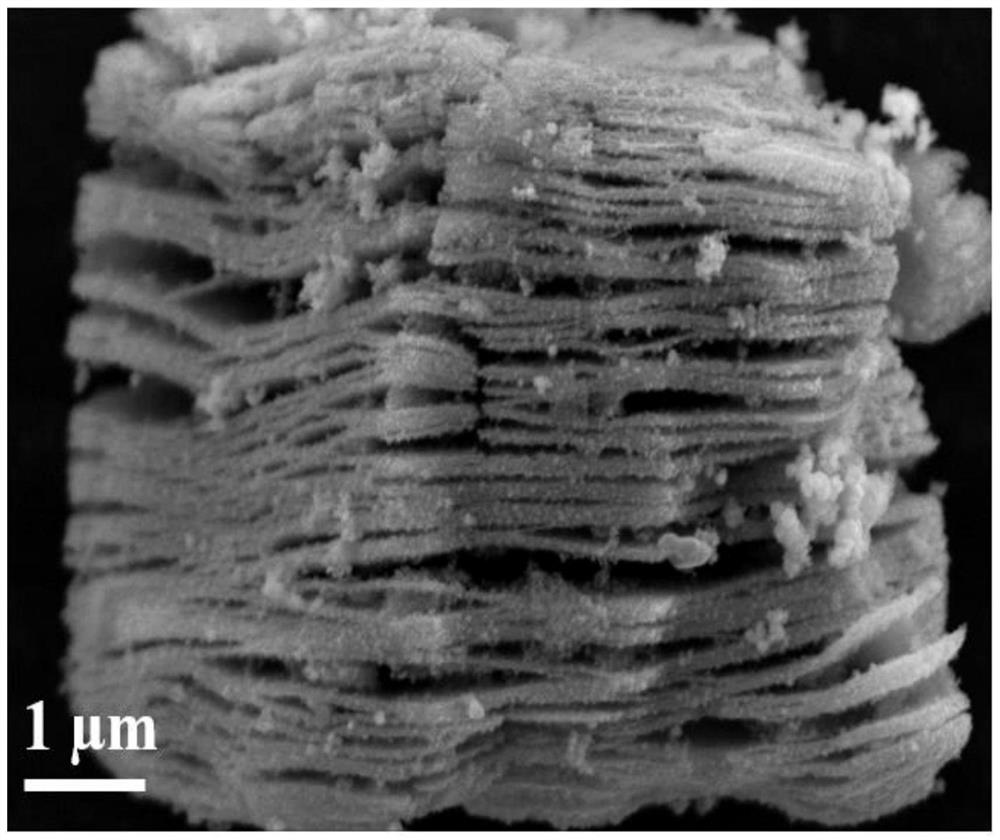

[0050] (2) 0.1mmol of MXene (Ti 3 C 2 T x ) nanosheets, suspension, 0.07 mmol of sulfur powder and 20 ml of ultrapure water were mixed, treated in an ultrasonic cleaner with an ultrasonic frequency of 50W for 0.5 h at 27°C, and then magnetically stirred for 5 h to obtain a mixed solution;

[0051] (3) Transfer the mixed solution into a reaction kettle with a capacity of 60ml, heat it to 180°C in a microwave oven, react for 12h, and cool it to room temperature naturally, then transfer the product to a centrifuge tube and centrifuge at 7500r / min for 5 min, the filter residue was washed three times with deionized water and absolute ethanol, and then dried in a vacuum oven to obtain a crude product, ...

Embodiment 3

[0056] A sulfur-doped ReSe 2 The preparation method of / MXene composite material, comprises the following steps:

[0057] (1) Add 0.2mmol of ReSe 2 Nanoparticles, 15ml of N,N-dimethylformamide (DMF) and 10ml of ultrapure water were fully stirred and mixed to obtain a suspension;

[0058] (2) 0.2mmol of MXene (Ti 3 C 2 T x ) nanosheets, suspension, 0.13 mmol of thiourea and 20 ml of ultrapure water were mixed, treated in an ultrasonic cleaner at 27° C. with an ultrasonic frequency of 50 W for 0.5 h, and then magnetically stirred for 4 h to obtain a mixed solution;

[0059] (3) Transfer the mixed solution into a reaction kettle with a capacity of 60ml, heat it to 180°C in a microwave oven, react for 12h, and cool it to room temperature naturally, then transfer the product to a centrifuge tube and centrifuge at 7500r / min for 5 min, the filter residue was washed three times with deionized water and absolute ethanol, and then dried in a vacuum oven to obtain a crude product, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap