a mote 2 /mxene composite material and preparation method thereof

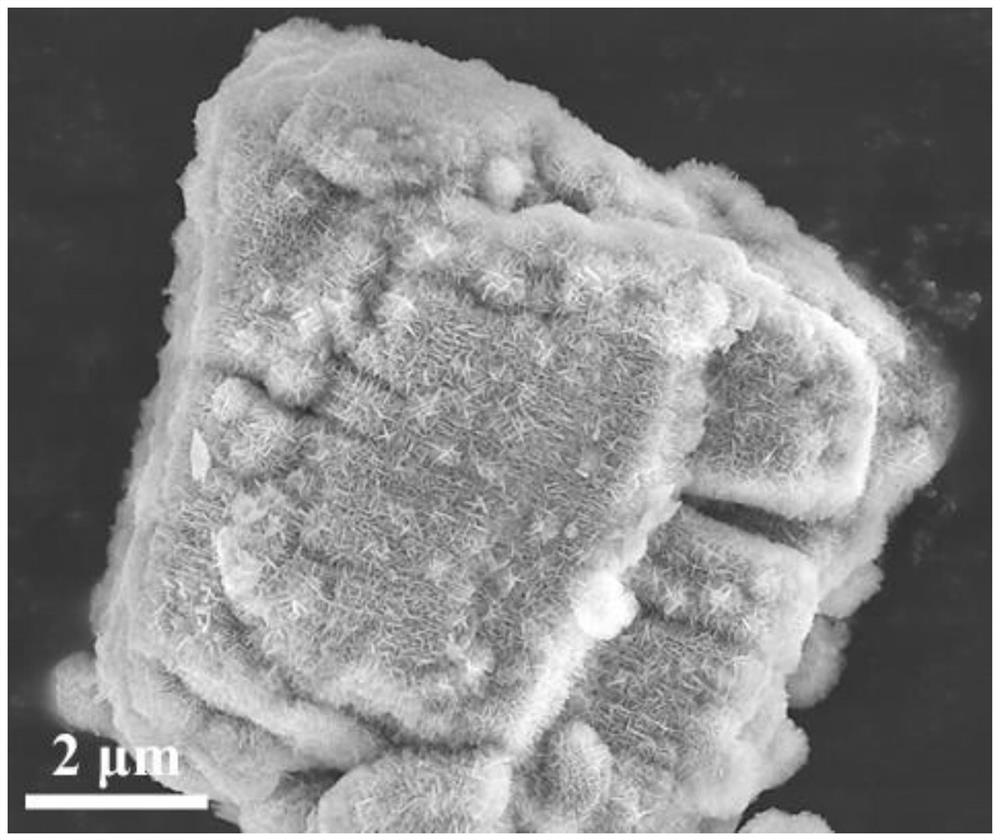

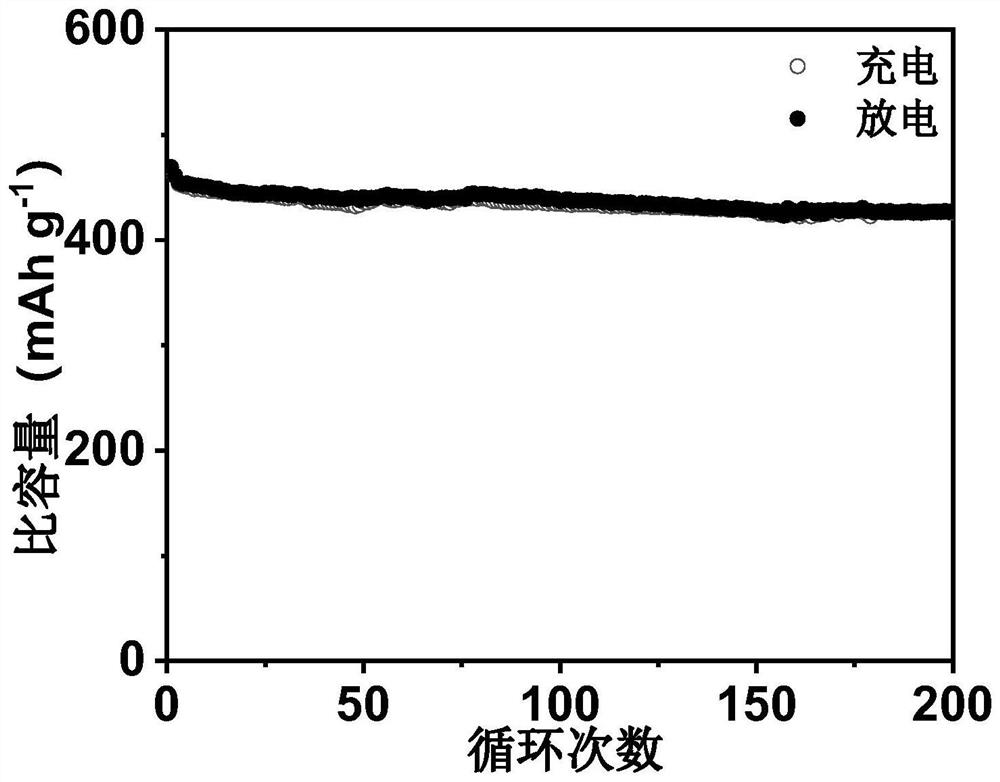

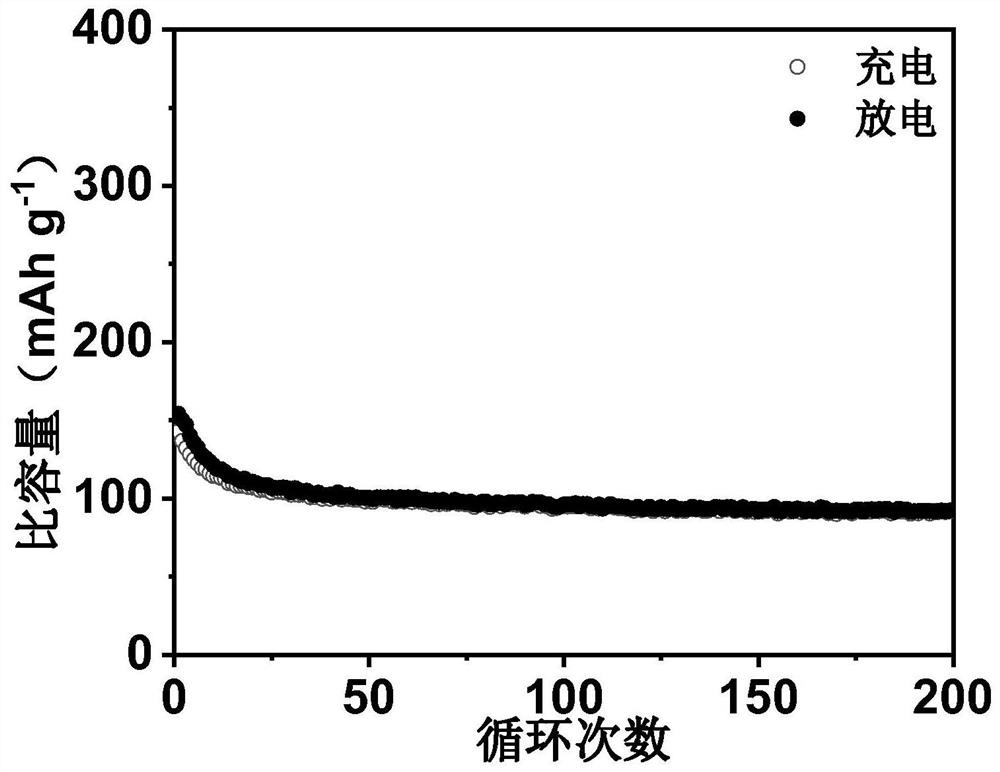

A composite material and potassium ion technology, applied in the field of MoTe2/MXene composite material and its preparation, can solve the problems of small interlayer spacing and the inability to obtain the effect of rapid ion migration, so as to increase the interlayer spacing, prevent pulverization and shedding, increase the The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a MoTe 2 The preparation method of / MXene composite material, wherein MoTe 2 For the synthesis method, please refer to:

[0038] "A flake semi-metallic MoTe 2 : Cu and flake semimetal MoTe 2 : Preparation method and process of Cu / RGO”

Embodiment 1

[0040] A MoTe 2 The preparation method of / MXene composite material specifically comprises the following steps:

[0041] (1) Take 300mg MXene (Ti 3 C 2 T x ) into ethylene glycol, magnetically stirred for 3 hours, and configured into a 10mg / ml dispersion;

[0042] (2) Add 0.1mol H 8 Mo 4 N 2 o 13 2H 2 O and 0.3mol potassium tellurite were added to the dispersion described in step (1), and stirred for 8 hours to obtain a suspension;

[0043] (3) Transfer the suspension obtained in step (2) into a reaction kettle with a capacity of 50ml, seal it and place it in an oven, heat it to 120°C, keep it warm for 12h, and then cool it down to room temperature;

[0044] (4) The product obtained in step (3) was centrifuged at 4000r / min for 5 minutes, and washed 3 times alternately with deionized water and absolute ethanol;

[0045] (5) Dry the product obtained in step (4) in a vacuum drying oven at a drying temperature of 60°C and a drying time of 10 hours to obtain MoTe 2 / MXene...

Embodiment 2

[0049] A MoTe 2 The preparation method of / MXene composite material specifically comprises the following steps:

[0050] (1) Take 900mg MXene (Ti 3 C 2 T x ) into ethylene glycol, magnetically stirred for 4 hours, and configured into a 30mg / ml dispersion;

[0051] (2) 0.3mol H 8 Mo 4 N 2 o 13 2H 2 O and 1.5mol potassium tellurite were added in the dispersion described in step (1), and stirred for 15 hours to obtain a suspension;

[0052] (3) Transfer the suspension obtained in step (2) into a reaction kettle with a capacity of 50ml, seal it and place it in an oven, heat it to 160°C, keep it warm for 18h, and then cool it to room temperature;

[0053] (4) The product obtained in step (3) was centrifuged at 6000r / min for 7 minutes, and washed 3 times alternately with deionized water and absolute ethanol;

[0054] (5) Dry the product obtained in step (4) in a vacuum drying oven at a drying temperature of 60°C and a drying time of 12 hours to obtain MoTe 2 / MXene composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap