Perovskite polycrystalline sheet and preparation method and application thereof

A technology of perovskite and perovskite precursors, which is applied in the preparation of amino compounds from amines, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., and can solve the problems of lack of perovskite thick film preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Add 1g of CH 2 NH 3 Dissolve I powder in 10mL of isopropanol, stir until dissolved at 80°C, then add 2g of PbI 2 The powder was poured into the solution, stirred for 2 hours, centrifuged three times to obtain solid perovskite powder, and dried at 60° C. for 12 hours to obtain perovskite powder.

[0040] 2. Put the perovskite powder into a circular mold, press high temperature and high pressure (10MPa, 150°C) for 5 hours, and then press the raw material into flakes to obtain perovskite polycrystalline flakes;

[0041] 3. Take out the cooled wafer, and vapor-deposit gold with a thickness of 50nm and 100nm on both sides as electrodes;

[0042] 4. Test the sensitivity of the prepared X-ray detector under different conditions.

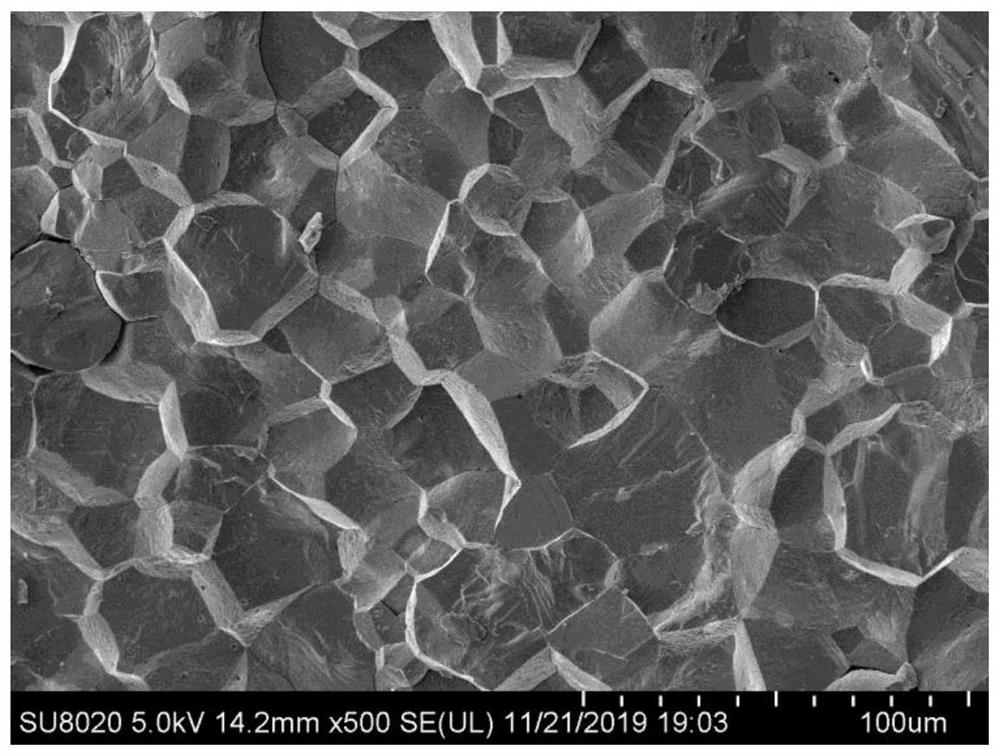

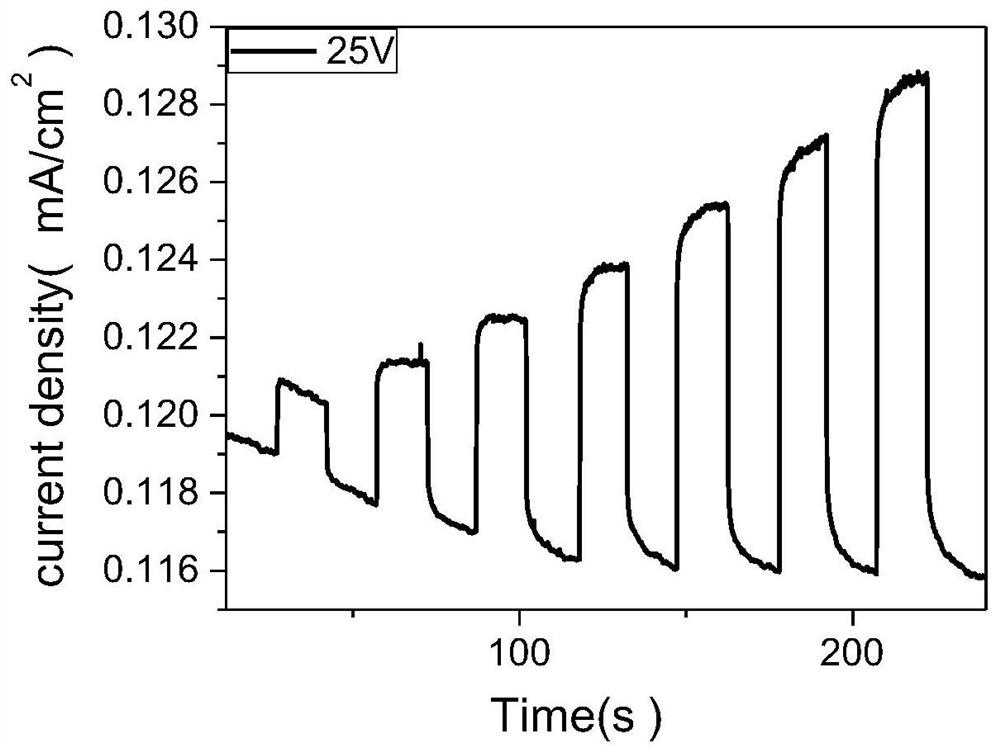

[0043] see figure 1 , do the X-ray detector for the perovskite multi-chip prepared in this embodiment, see figure 2 Make the metallographic diagram of the perovskite polycrystalline flake for this embodiment, as can be seen from the figure, th...

Embodiment 2

[0045] 1. Add 1g of CH 2 NH 3 Dissolve Br powder in 10mL of isopropanol, stir until dissolved at 80°C, then add 2g of PbBr 2 The powder was poured into the solution, stirred for 2 hours, centrifuged three times, and dried at 80° C. for 12 hours to obtain the perovskite powder.

[0046] 2. Put the perovskite powder into a circular mold, press high temperature and high pressure (10MPa, 150°C) for 8 hours, and then press the raw material into flakes to obtain perovskite polycrystalline flakes;

[0047] 3. Take out the cooled wafer, spin-coat an electron transport layer (20mg / mL PCBM solution) on one side, and leave the other side untreated;

[0048] 4. Take out the spin-coated wafer, and vapor-deposit gold with a thickness of 50nm and 100nm on both sides as electrodes;

[0049] 5. Test the sensitivity of the prepared X-ray detector under different conditions.

Embodiment 3

[0051] 1. Dissolve 1.5g of CsBr powder in 10mL of isopropanol, stir until dissolved at 80°C, then dissolve 2g of PbBr 2 The powder was poured into the solution, stirred for 2 hours, centrifuged three times, and dried at 100° C. for 12 hours to obtain the perovskite powder.

[0052] 2. Put the perovskite powder into a circular mold, and press the raw material into flakes by means of high temperature and high pressure (10MPa, 150°C, 1h) to obtain perovskite polycrystalline flakes;

[0053] 3. Take out the cooled wafer, and spin-coat electron transport layers (20 mg / mL PCBM solution) on both sides of the wafer;

[0054] 4. Take out the spin-coated wafer, and vapor-deposit gold with a thickness of 50nm and 100nm on both sides as electrodes;

[0055] 5. Test the sensitivity of the prepared X-ray detector under different conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com