High-performance concrete with C80 strength grade, and preparation method of high-performance concrete

A high-performance concrete and strength grade technology, applied in the field of concrete, can solve the problems of concrete structure corrosion, bridge cracking, safety hazards, etc., and achieve the effect of promoting hydration, improving microstructure, and improving overall strength and comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

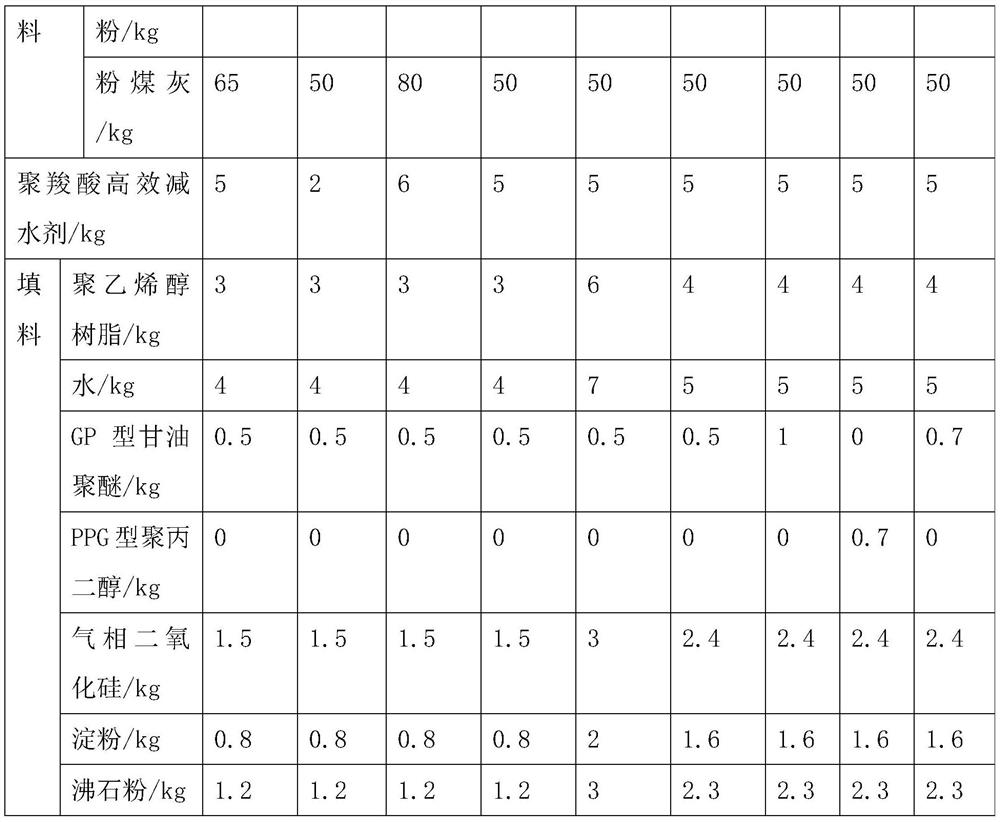

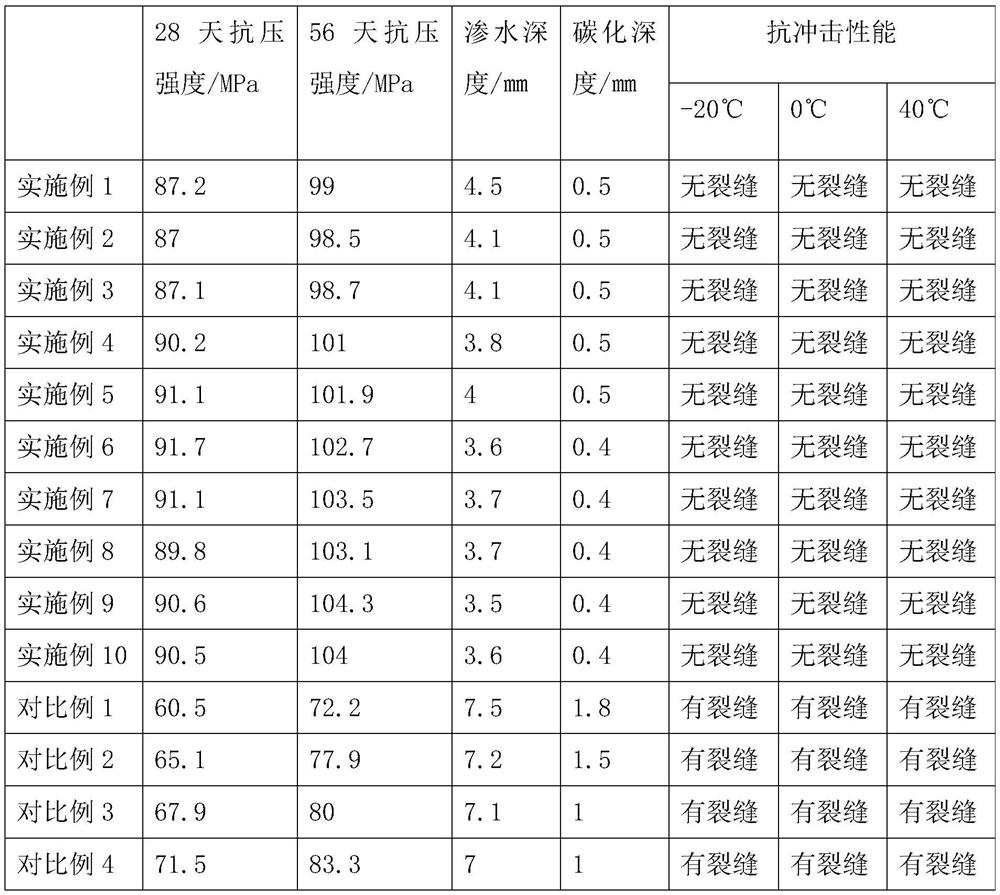

[0040] A high-performance concrete of C80 strength grade, including the following components by weight: water 140kg, Portland cement 374kg, sand 600kg, crushed stone 1164kg, silica fume 31kg, mineral admixture 115kg, poly Carboxylic acid superplasticizer 5kg, filler 12kg; filler includes the following raw materials: polyvinyl alcohol resin 3kg, water 4kg, defoamer 0.5kg, fumed silica 1.5kg, starch 0.8kg, zeolite Powder 1.2kg;

[0041] The Portland cement used is P·O52.5R grade Portland cement. The sand is medium-coarse machine-made sand with a well-graded limestone quality. The fineness modulus is 2.5-3.1, and the preferred fineness modulus is 2.8. Stone selection of 5-20mm continuous graded limestone crushed stone;

[0042] The mineral admixture used is composed of 50kg of fly ash and 65kg of granulated blast furnace slag powder. The fly ash used is high-quality Class I fly ash, and the loose bulk density of the fly ash is 800kg / m 3 , the water demand ratio is not more than...

Embodiment 10

[0057] The difference with Example 9 is that a preparation method of high-performance concrete of C80 strength grade comprises the following steps:

[0058] Step 1: preparing filler;

[0059] The preparation of packing comprises the following steps:

[0060] Step 1: Dissolve polyvinyl alcohol resin and defoamer in water at 30°C, stir slowly to make the polyvinyl alcohol resin fully swell, and heat up to 80°C at a heating rate of 2-3°C while stirring, so that the polyethylene Alcohol resin accelerates dissolving, heat preservation 2 hours, makes polyvinyl alcohol resin solution;

[0061] Step 2: Add starch and fumed silica to the polyvinyl alcohol resin solution in turn while stirring to obtain a suspension, and evaporate the suspension to dryness at a temperature of 85°C for 30 minutes to dry the water Afterwards, semi-finished products are produced;

[0062] Step 3: After uniformly mixing the semi-finished product and zeolite powder prepared in step 3, extruding and granul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com