Method for improving protein in biomass raw material through kitchen residue fermentation

A technology for kitchen residues and biomass raw materials, which is applied to fertilizers made of biological wastes, microbial treatment, combined biological treatment, etc., can solve the problems of low nutrient content, low quality of finished products, and low absorption and utilization rate of crops, etc. Achieve the effect of improving soil structure, improving utilization performance, and improving the internal and external environment of crops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

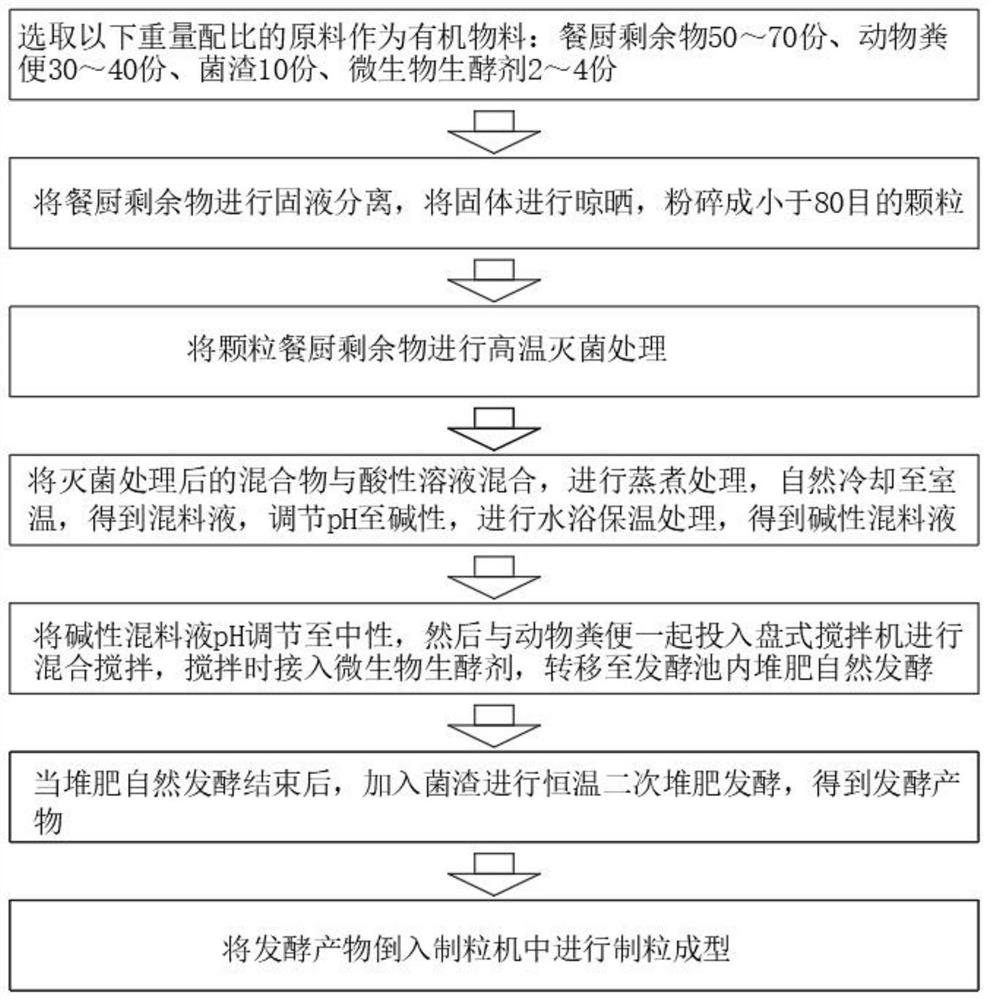

[0029] A method for fermenting kitchen residues to increase protein in biomass raw materials, comprising the following steps:

[0030] Step 1. Select the raw materials in the following weight proportions as organic materials: 50 parts of kitchen residues, 30 parts of animal manure, 10 parts of fungus residue, and 2 parts of microbial starter;

[0031] Step 2: Separating the kitchen residues from solid to liquid, drying the separated solids for no less than 48 hours, sending the dried solids into a pulverizer to be crushed into particles of uniform size and texture, less than 80 mesh ;

[0032] Step 3, subjecting 50 parts of the granular kitchen residues obtained in step 2 to high-temperature sterilization;

[0033] Step 4. After mixing the sterilized mixture in step 4 with the acidic solution, then carry out cooking treatment, and then naturally cool to room temperature to obtain a mixed material liquid, adjust the pH of the mixed material liquid to be alkaline, and then perf...

Embodiment 2

[0044] A method for fermenting kitchen residues to increase protein in biomass raw materials, comprising the following steps:

[0045] Step 1. Select the raw materials in the following weight proportions as organic materials: 70 parts of kitchen residues, 40 parts of animal manure, 10 parts of fungus residue, and 4 parts of microbial starter;

[0046] Step 2: Separating the kitchen residues from solid to liquid, drying the separated solids for no less than 48 hours, sending the dried solids into a pulverizer to be crushed into particles of uniform size and texture, less than 80 mesh ;

[0047] Step 3, subjecting 70 parts of the granular kitchen residues obtained in step 2 to high-temperature sterilization;

[0048] Step 4. After mixing the sterilized mixture in step 4 with the acidic solution, then carry out cooking treatment, and then naturally cool to room temperature to obtain a mixed material liquid, adjust the pH of the mixed material liquid to be alkaline, and then perf...

Embodiment 3

[0059] A method for fermenting kitchen residues to increase protein in biomass raw materials, comprising the following steps:

[0060] Step 1. Select the raw materials in the following weight proportions as organic materials: 60 parts of kitchen residues, 35 parts of animal manure, 10 parts of fungus residue, and 3 parts of microbial starter;

[0061] Step 2: Separating the kitchen residues from solid to liquid, drying the separated solids for no less than 48 hours, sending the dried solids into a pulverizer to be crushed into particles of uniform size and texture, less than 80 mesh ;

[0062] Step 3, subjecting 60 parts of the granular kitchen residues obtained in step 2 to high-temperature sterilization;

[0063] Step 4. After mixing the sterilized mixture in step 4 with the acidic solution, then carry out cooking treatment, and then naturally cool to room temperature to obtain a mixed material liquid, adjust the pH of the mixed material liquid to be alkaline, and then perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com