UV-cured water-based anti-yellowing white wood lacquer and preparation method thereof

A technology of anti-yellowing and wood paint, applied in the field of coatings, can solve the problems of poor light curing performance and poor anti-yellowing of paint film, and achieve the effects of fast curing speed, good adhesion, excellent water resistance and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

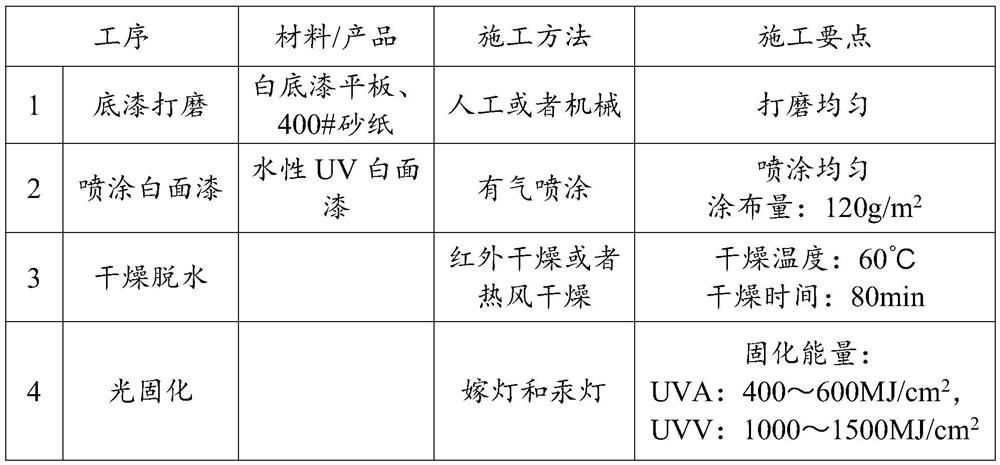

Method used

Image

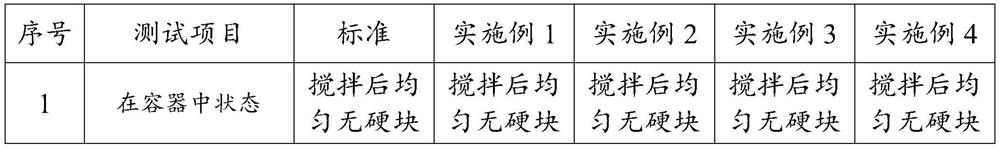

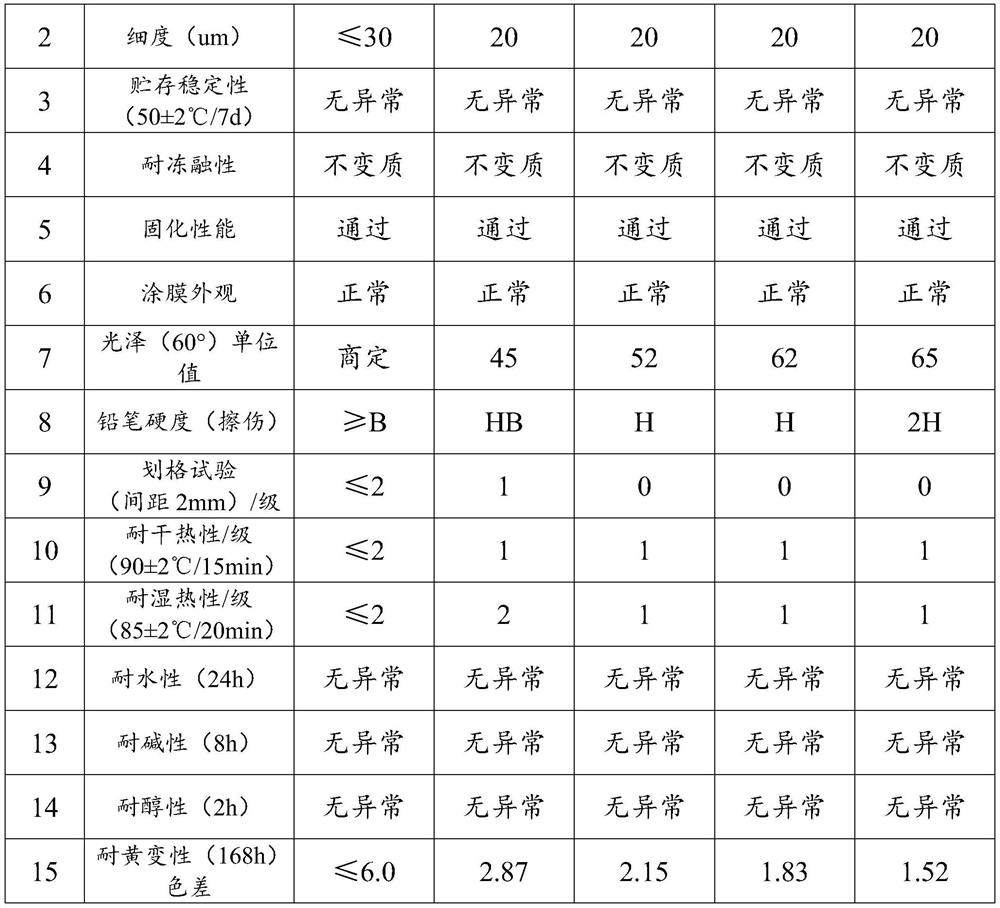

Examples

Embodiment 1

[0030] A UV-cured water-based anti-yellowing white wood paint, made of the following mass fractions of raw materials: water-based UV resin NeoRez R-465: 60.0%, thickener 1 (PUR299): 0.5%, photoinitiator TPO-L : 3.0%, photoinitiator 819DW: 1.0%, titanium dioxide R706: 17.0%, wetting and dispersing agent TEGO755W: 0.8%, substrate wetting agent BYK3455: 0.8%, foam suppressor BYK-028: 0.1%, defoaming Agent TEGO-902W: 0.2%, antifoaming agent BYK-024: 0.3%, thickener 2 (PUR299): 0.2%, deionized water: 16.1%.

[0031] The preparation method of the water-based anti-yellowing white wood paint of this UV curing is:

[0032] (1) Add the water-based UV resin NeoRez R-465 into the dispersing tank, and add thickener 1, photoinitiator TPO-L, photoinitiator 819DW, and wetting and dispersing agent TEGO755W in sequence while stirring at a speed of 500r / min , Antifoaming agent BYK-028, defoaming agent TEGO-902W, antifoaming agent BYK-024, titanium dioxide R706, substrate wetting agent BYK3455, ...

Embodiment 2

[0035] A UV-cured water-based anti-yellowing white wood paint, made of the following mass fractions of raw materials: water-based UV resin NeoRez R-465: 65.0%, thickener 1 (PUR299): 0.4% photoinitiator TPO-L: 2.0%, photoinitiator 819DW: 1.0%, titanium dioxide R706: 15.0%, wetting and dispersing agent TEGO755W: 1.0%, substrate wetting agent BYK3455: 0.8%, foam suppressor BYK-028: 0.1%, defoaming agent TEGO-902W: 0.2%, defoamer BYK-024: 0.3%, thickener 2 (PUR40): 0.3%, deionized water: 9.5%.

[0036] The preparation method of the water-based anti-yellowing white wood paint of this UV curing is:

[0037] (1) Add the water-based UV resin NeoRez R-465 into the dispersing tank, and add thickener 1, photoinitiator TPO-L, photoinitiator 819DW, and wetting and dispersing agent in sequence under stirring at a speed of 350r / min TEGO755W, antifoaming agent BYK-028, defoaming agent TEGO-902W, antifoaming agent BYK-024, titanium dioxide R706, substrate wetting agent BYK3455, after stirring...

Embodiment 3

[0040] A UV-cured water-based anti-yellowing white wood paint, made of the following mass fractions of raw materials: water-based UV resin NeoRez R-465: 70.0%, thickener 1 (PUR299): 0.4%, photoinitiator TPO-L : 2.0%, photoinitiator 819DW: 1.0%, titanium dioxide R706: 15.0%, wetting and dispersing agent TEGO755W: 0.8%, substrate wetting agent BYK3455: 0.8%, foam suppressor BYK-028: 0.1%, defoaming Agent TEGO-902W: 0.2%, antifoaming agent BYK-024: 0.3%, thickener 2 (PUR299): 0.2%, deionized water: 10.8%.

[0041] The preparation method of the water-based anti-yellowing white wood paint of this UV curing is:

[0042](1) Add the water-based UV resin NeoRez R-465 into the dispersion tank, and add thickener 1, photoinitiator TPO-L, photoinitiator 819DW, and wetting and dispersing agent TEGO755W in turn under stirring at a speed of 400r / min , Antifoaming agent BYK-028, defoaming agent TEGO-902W, antifoaming agent BYK-0 24, titanium dioxide R706, substrate wetting agent BYK3455, afte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap