Preparation method and application of aluminum-containing alloy powder and alloy strip

A technology of aluminum alloy powder and alloy, applied in metal processing equipment, transportation and packaging, coating, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

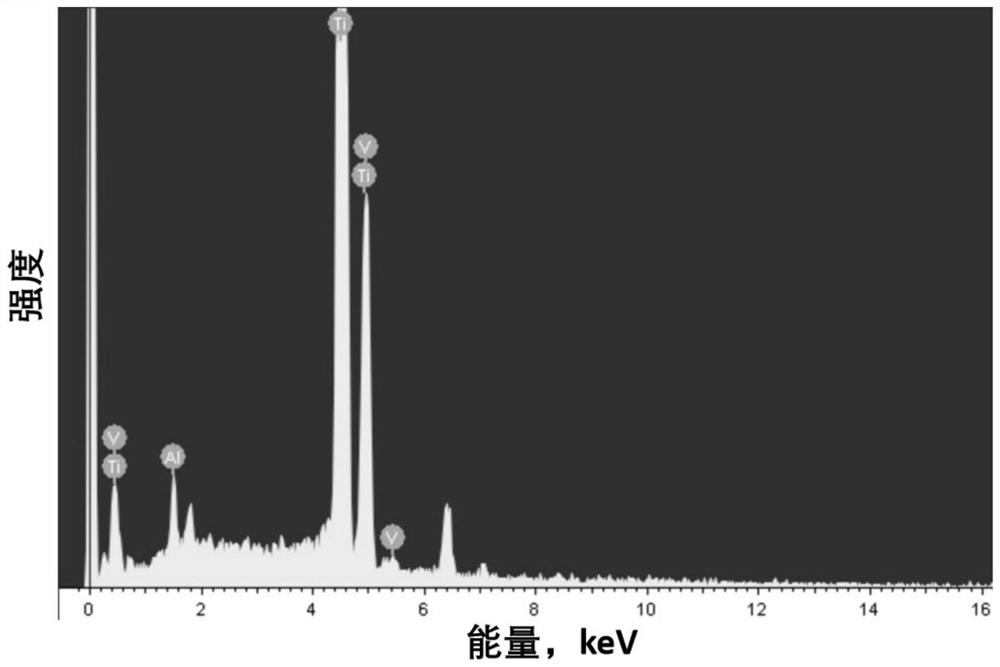

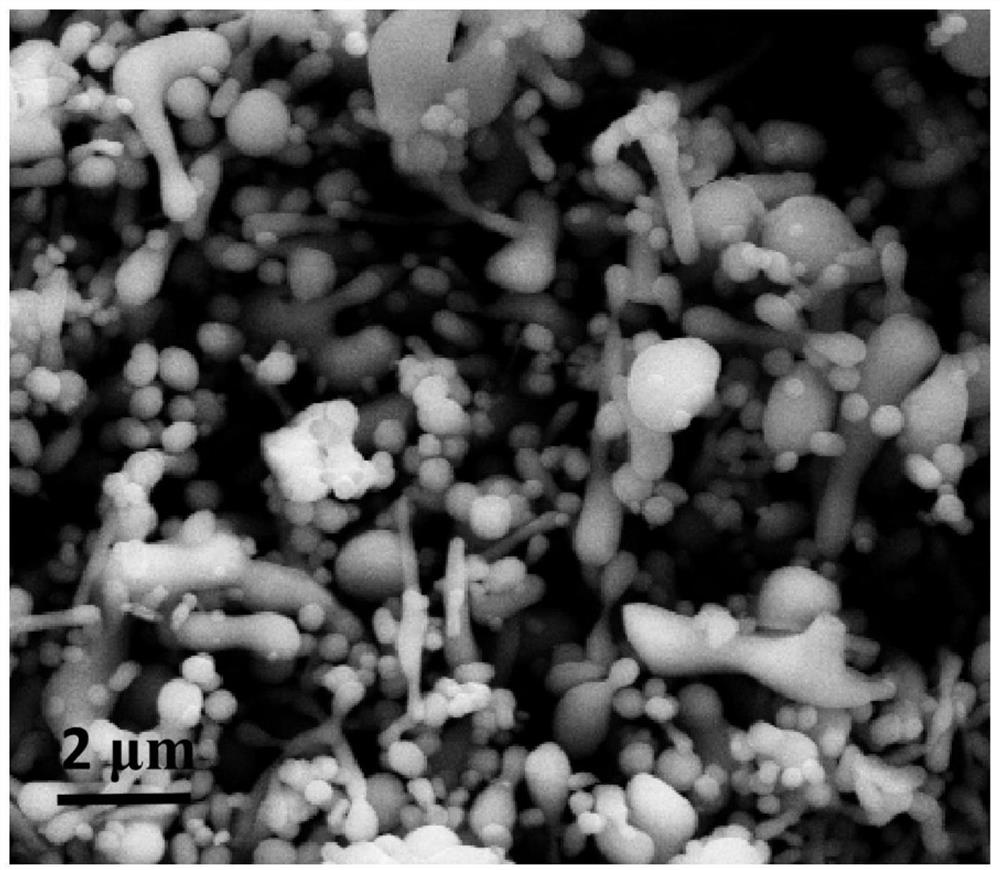

[0131] This embodiment provides a method for preparing a micron-sized Ti-V-Cr-Mo-Zr-Al alloy powder, the preparation method comprising the following steps:

[0132] (1) According to Gd 76 al 8 (Ti 82 V 8 Cr 6 Mo 2 Zr 2 ) 16 The formula of the alloy (atomic percentage) weighs the raw material, and obtains Gd after arc melting 76 al 8 (Ti 82 V 8 Cr 6 Mo 2 Zr 2 ) 16 master alloy. The master alloy is reheated and melted into an alloy melt by induction melting, and the alloy melt is prepared at a solidification rate of 10K / s-1000K / s into Gd with a thickness of 1mm-20mm 76 al 8 (Ti 82 V 8 Cr 6 Mo 2 Zr 2 ) 16 alloy sheet. The solidification structure of the alloy sheet is from the average composition of about Gd 91.5 al 8.5 The matrix phase and composition of (Ti 82 V 8 Cr 6 Mo 2 Zr 2 ) 94.5 al 5.5 The composition of the dispersed dendrite particle phase, and the particle size of the dispersed particle phase is 1 μm to 200 μm.

[0133] (2) At room tem...

Embodiment 2

[0135] This embodiment provides a method for preparing a micron-sized Ti-Mo-Zr-Al alloy powder, the preparation method comprising the following steps:

[0136] (1) According to Ce 76 al 8 (Ti 98 Mo 1 Zr 1 ) 16 The formula of the alloy (atomic percentage) weighs the raw materials, and obtains Ce after arc melting 76 al 8 (Ti 98 Mo 1 Zr 1 ) 16 master alloy. The master alloy is reheated and melted into an alloy melt by induction melting, and the alloy melt is prepared at a solidification rate of 10K / s-1000K / s into Ce with a thickness of 1mm-20mm 76 al 8 (Ti 98 Mo 1 Zr 1 ) 16 alloy sheet. The solidified structure of the alloy sheet is from an average composition of about Ce 91.5 al 8.5 The matrix phase and composition of (Ti 98 Mo 1 Zr 1 ) 94.5 al 5.5 The composition of the dispersed dendrite particle phase, and the size of the dispersed particle phase is 1 μm to 200 μm.

[0137] (2) At room temperature, 1 gram of Ce prepared in step (1) 76 al 8 (Ti 98 ...

Embodiment 3

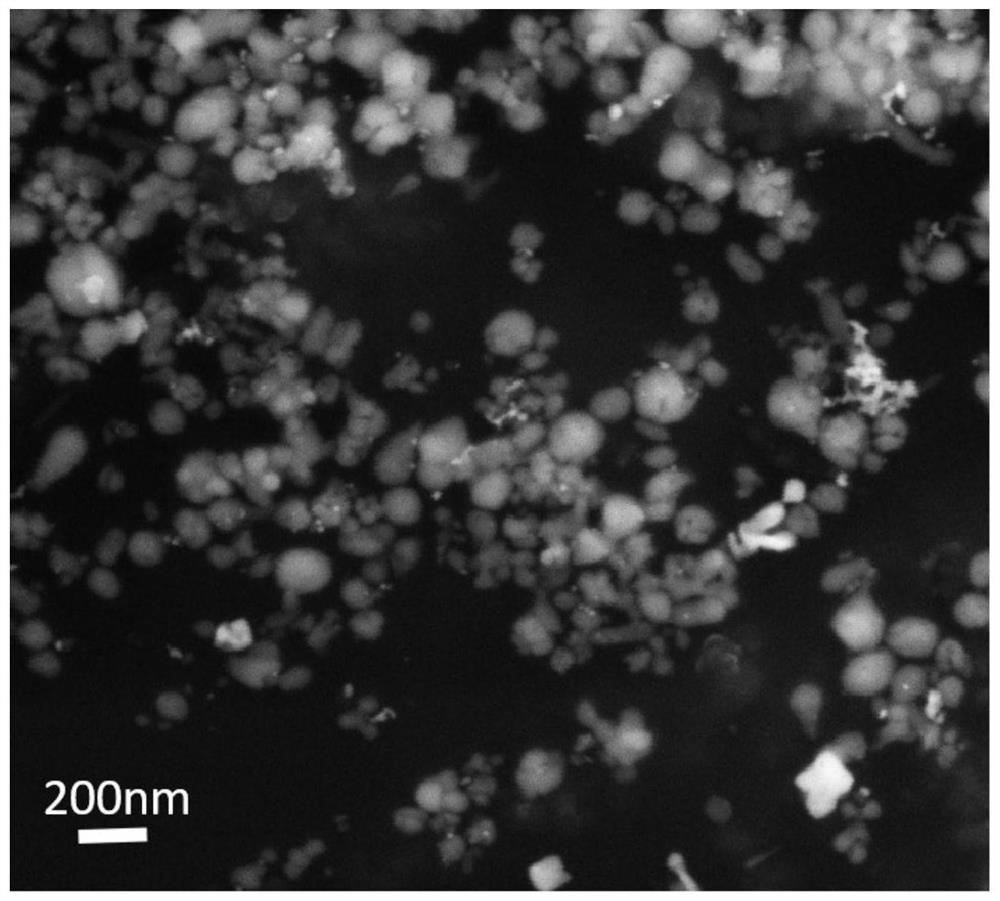

[0139] This embodiment provides a preparation method of nanoscale Ti-Cr-Al alloy powder, the preparation method comprising the following steps:

[0140] (1) According to Ce 72 al 12 (Ti 97.5 Cr 2.5 ) 16 The formula of the alloy (atomic percentage) weighs the raw material, and obtains molten Ce after induction melting 72 al 12 (Ti 97.5 Cr 2.5 ) 16 alloy melt. The method of passing the alloy melt through the copper roller to throw the belt takes ~10 5 The rate of K / s is prepared into Ce with a thickness of 20 μm to 100 μm 72 al 12 (Ti 97.5 Cr 2.5 ) 16 alloy strip. The solidified structure of the alloy strip has an average composition of about Ce 87 al 13 The matrix phase and composition of (Ti 97.5 Cr 2.5 ) 91.5 al 8.5 The composition of the dispersed particle phase, and the size of the dispersed particle phase is 10nm to 200nm, and the shape is nearly spherical.

[0141] (2) At room temperature, 1 gram of Ce prepared in step (1) 72 al 12 (Ti 97.5 Cr 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com