High-temperature corrosion-resistant coating and preparation method thereof, and high-temperature corrosion-resistant material

A corrosion-resistant, high-temperature technology, applied in the field of high-temperature corrosion-resistant materials and their preparation, to achieve the effects of high safety, short production cycle, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

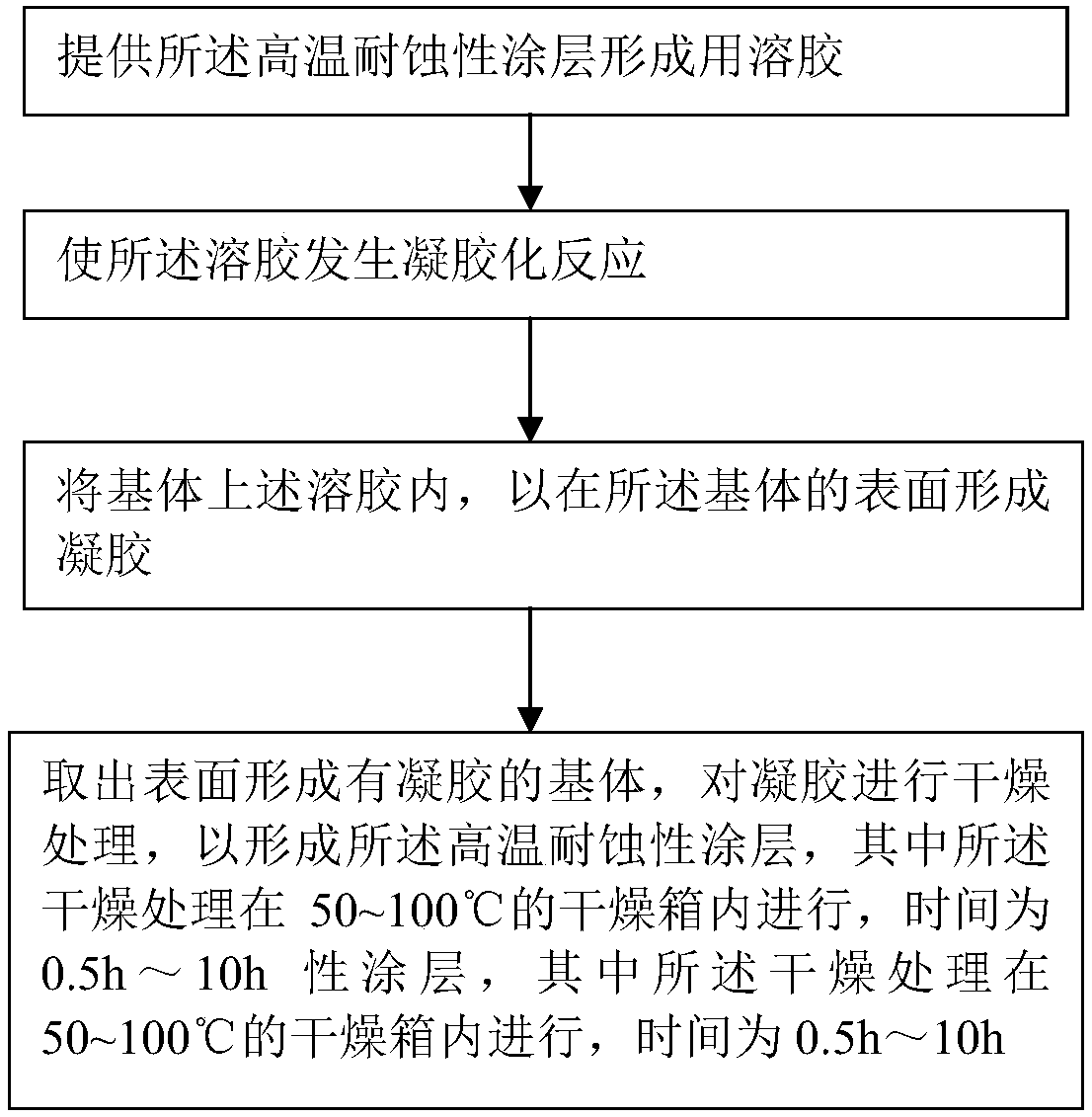

[0036] Such as figure 1 As shown, the preparation method of the high-temperature corrosion-resistant coating according to the embodiment of the present invention includes the following steps:

[0037] 1) providing the sol for forming the high-temperature corrosion-resistant coating;

[0038] It should be noted that the sol can be a commercially available sol, or a sol obtained by the following method:

[0039] 1.1) Disperse the precursor in a solvent to form a precursor dispersion

[0040] The solvent may be water, ethanol, isopropanol, benzyl alcohol, dimethylformamide and mixtures thereof, wherein water, ethanol, isopropanol and mixtures thereof are preferred, especially water, ethanol and mixtures thereof.

[0041] Wherein, the precursor may be a silicon precursor, a titanium precursor, or a mixture of a titanium precursor and a zirconium precursor.

[0042] Wherein, the silicon precursor includes: tetraethylorthosilicate (TEOS), methylorthosilicate (TMOS), methylsilicat...

Embodiment 1

[0069] Take 1 part of ammonia-stabilized silica sol, add 0.5 part of ethanol solvent and mix evenly, then add 0.1 part of 1% oxalic acid to adjust the pH to 5-6.

[0070] After that, put the matrix after ultrasonic cleaning with water, ethanol, and acetone, then irradiate with ultraviolet light and dry it in the above sol, gel after about ten minutes, then put it in an oven at 70°C for 12 hours, and then take it out and wash it with distilled water for 3 times, and then placed in an oven at 80 ° C for 1 h to obtain SiO 2 Coated modified substrate.

[0071] Its corresponding electron micrograph is shown in figure 2 shown.

[0072] Its corrosion resistance (Table 1) is at 0.5M H 2 SO 4 solution until the surface is corroded by naked eyes, record the time until the surface corrodes. The high temperature corrosion resistance is judged according to the 6h anti-oxidation test in a muffle furnace at 800°C, and by comparing the weight gain.

[0073] In Table 1, for comparison, ...

Embodiment 2

[0077] Take 1L (3.21M) of fluosilicic acid, add a certain amount of silicic acid to saturation, then add 0.18L of boric acid (0.1M), mix well, put the treated substrate into the above deposition solution, and place it in an 80°C The deposition reaction was carried out in an oven for 8 hours, and then the obtained samples were washed several times with distilled water, and dried in an oven at 80° C. for 1 hour.

[0078] Thereafter, heat treatment was performed at 900 °C for 2 hours to obtain a silica-coated substrate sample.

[0079] Its electron microscope picture is as image 3 shown.

[0080] Its corrosion resistance (Table 2) is at 0.5M H 2 SO 4 solution until the surface is corroded by naked eyes, record the time until the surface corrodes. The high temperature corrosion resistance is judged according to the 6h anti-oxidation test in a muffle furnace at 800°C, and by comparing the weight gain.

[0081] In Table 2, for comparison, the related experimental data of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com