Corrosion-resistant metal porous material and preparation method and application thereof

A metal porous and corrosion-resistant technology, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of reducing the activation energy of chemical reactions, large specific surface area of metal porous materials, and shortened service life. Achieve excellent filtration performance, reduce coarse grain size, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

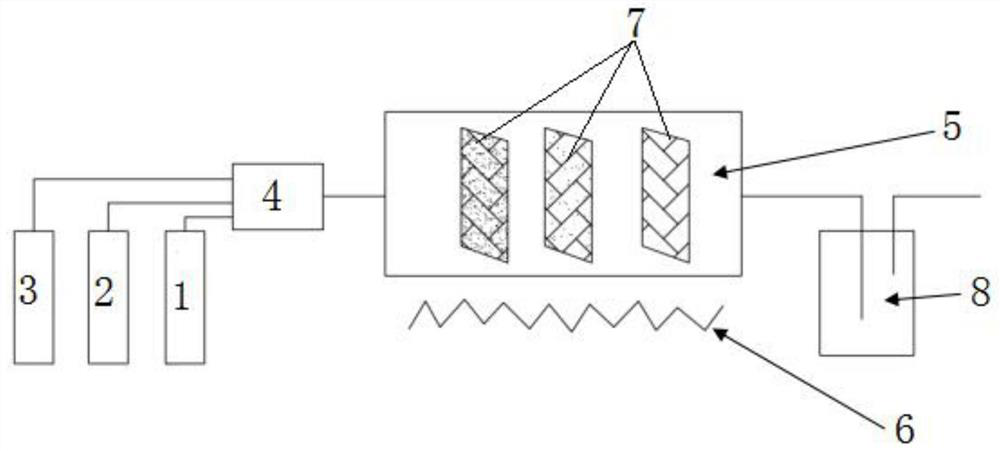

[0033] The present invention provides the preparation method of the corrosion-resistant metal porous material according to the above technical solution, comprising the following steps:

[0034] The metal porous material substrate is heated, and the precursor gas of Ta and / or Mo is introduced perpendicular to the surface direction of the metal porous material substrate to carry out chemical vapor deposition, and a metal is formed on the surface of the porous skeleton of the metal porous material substrate. A Ta layer, a metal Mo layer or an alternate composite layer of a metal Ta layer and a metal Mo layer to obtain the corrosion-resistant metal porous material;

[0035] The precursor gas is a halide or an organic complex; when the precursor gas is a halide, a reducing gas is also introduced.

[0036] The present invention heats the metallic porous material substrate. Before heating, in the present invention, the porous metal material substrate is preferably pretreated; the pr...

Embodiment 1

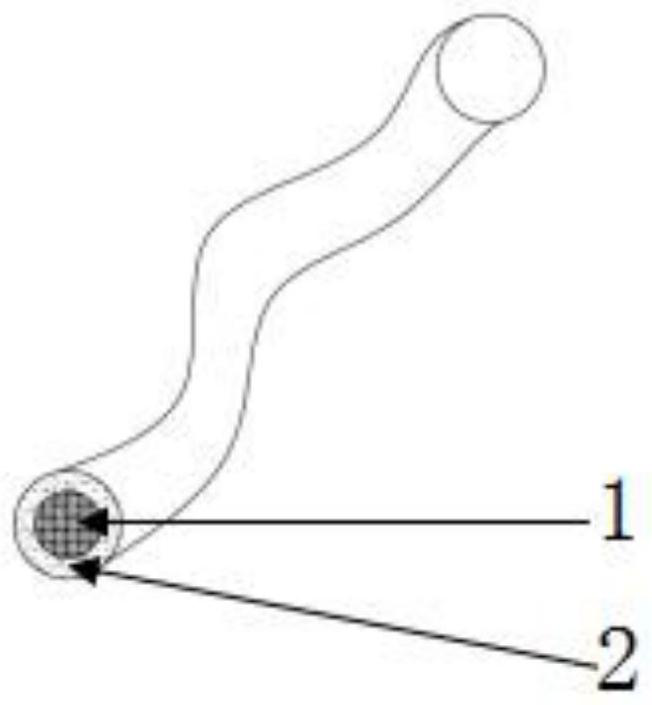

[0061] A titanium fiber sintered plate with a porosity of 80% and an average wire diameter of 65 μm was selected as the base material, and thermally activated chemical vapor deposition (CVD) Ta was performed on its surface to prepare a corrosion-resistant full-through-hole metal fiber sintered body, which can be used as fuel For battery bipolar plates, the process is as follows:

[0062] After the titanium fiber sintered plate was sequentially washed with alkali, acid, deionized water and dried, it was placed in a chemical vapor deposition reaction chamber; the TaF 5 The solid material is heated to above the boiling point (229.2°C) by a constant temperature heater under normal pressure to make TaF 5 gas, with H 2 Mixed into the deposition reaction chamber, the flow direction is perpendicular to the direction of the titanium fiber sintered plate, and the molar ratio of the two gases is TaF 5 :H 2 =1:2.5, TaF 5 The flow rate is 1g / min, H 2 The flow rate is 1L / min, the carri...

Embodiment 2

[0066] Plasma-enhanced chemical vapor deposition (PECVD) was used to deposit a Ta corrosion-resistant layer on a 3D printed TC4 porous material with a porosity of 70% to prepare a corrosion-resistant 3D printed TC4 porous material, which can be used as a metal porous implant. The process is as follows:

[0067] The 3D printed TC4 porous material was sequentially subjected to alkaline washing, acid washing, deionized water washing and drying, and then placed in a chemical vapor deposition reaction chamber. TaCl 5 The solid material is heated above 150°C in a sealed evaporator to produce TaCl 5 The vapor pressure of the gas is 800Pa. Under the action of its own pressure, TaCl 5 Precursor gas directly into the deposition reaction chamber without carrier gas assisted transport, TaCl 5 The precursor gas flow rate was 3 g / min, H 2 The flow rate is 3L / min, and the molar ratio of the two gases is TaCl 5 :H 2 =1:6, the flow direction of the reaction gas is perpendicular to the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com