Method for producing porous three-dimensional material by enzymatic degradation of PCL/PLLA polymer

A polymer and three-dimensional technology, applied in the biochemical treatment of enzymes/microorganisms, conjugated synthetic polymer artificial filaments, biochemical fiber treatment, etc., can solve the problems of less pore structure and no potential for ideal scaffolds, etc., and meet low requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for producing porous three-dimensional materials by enzymatically degrading PCL / PLLA polymers, comprising the following steps:

[0025] Step 1, dissolve PCL and PLLA with a mass ratio of 7:3 in a mixed solvent of dichloromethane and N,N-dimethylamide (the volume ratio of dichloromethane and N,N-dimethylamide is 3:1 ), obtain the PCL / PLLA solution of 10% by mass percentage;

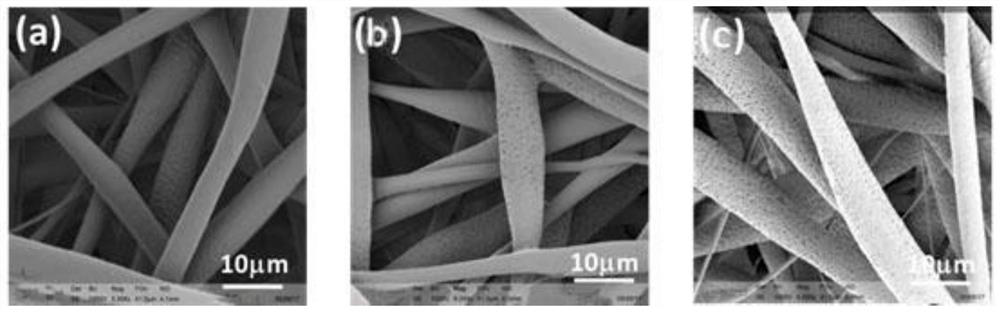

[0026] Step 2, put the PCL / PLLA solution into a high-voltage electrospinning device for electrospinning. The technical parameters of the electrospinning are: spinning voltage 20kv, needle distance 20cm, drum speed 3000r / min, and the pump moves The speed is 50μm / s to obtain PCL / PLLA fiber membrane;

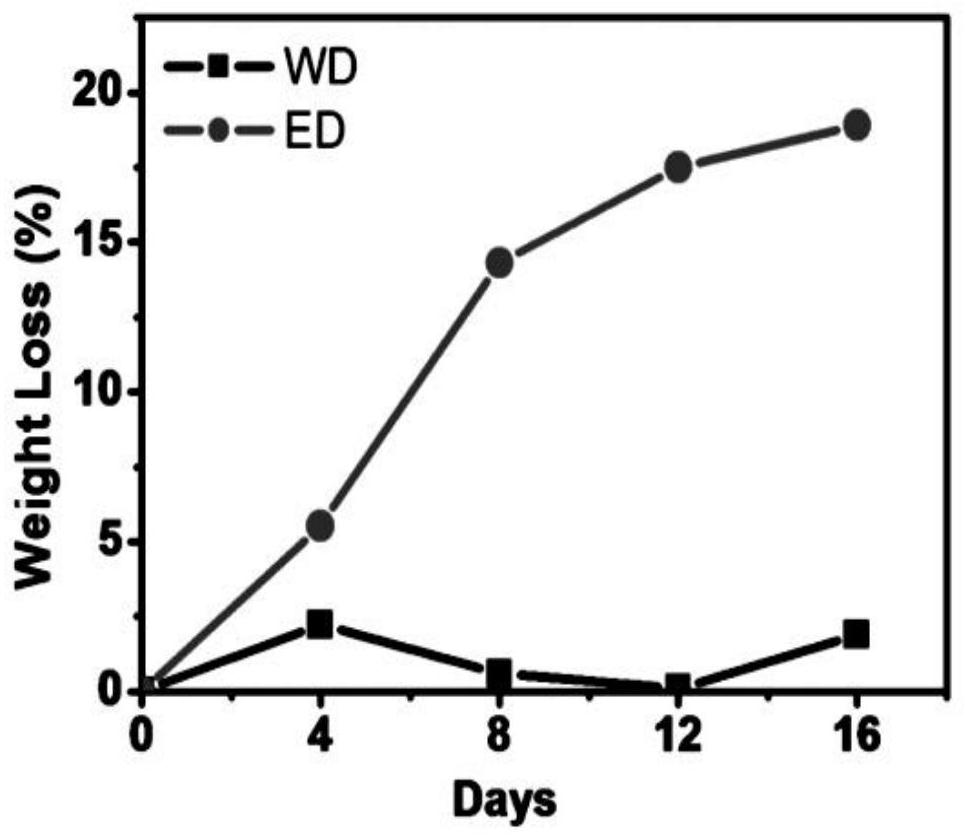

[0027] Step 3: Rinse the PCL / PLLA fiber membrane with alcohol and dry it thoroughly in a vacuum oven at a preset temperature of 40°C, and then place it in PBS buffer solution with esterase for degradation. The degradation time is 8 days. The concentration of the enzyme is 0.1mg / ml, the degrada...

Embodiment 2

[0029] A method for producing porous three-dimensional materials by enzymatically degrading PCL / PLLA polymers, comprising the following steps:

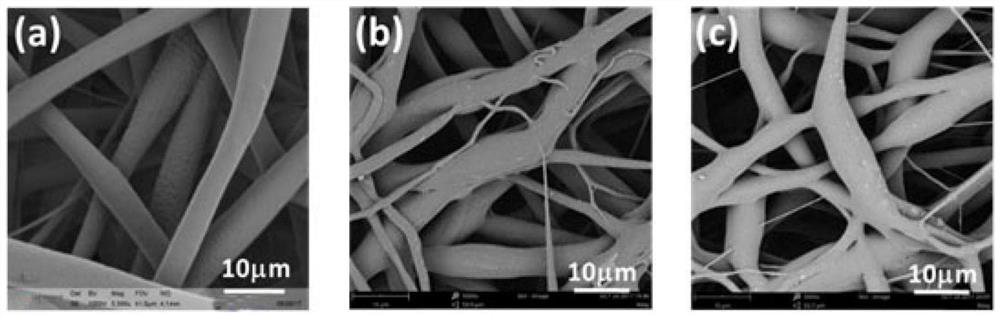

[0030] Step 1, dissolve PCL and PLLA with a mass ratio of 10:1 in a mixed solvent of dichloromethane and N,N-dimethylamide (the volume ratio of dichloromethane and N,N-dimethylamide is 4:1 ), obtain the PCL / PLLA solution of 5% by mass percent;

[0031] Step 2, put the PCL / PLLA solution into a high-voltage electrospinning device for electrospinning. The technical parameters of the electrospinning are: spinning voltage 10kv, needle distance 30cm, drum speed 2000r / min, and the pump moves The speed is 0.1μm / s, and the PCL / PLLA fiber membrane is obtained;

[0032] Step 3: Rinse the PCL / PLLA fiber membrane with alcohol and dry it thoroughly in a vacuum oven at a preset temperature of 40°C, and then place it in PBS buffer solution with esterase added for degradation. The concentration of esterase is 0.5mg / ml, the degradation temperature i...

Embodiment 3

[0034] A method for producing porous three-dimensional materials by enzymatically degrading PCL / PLLA polymers, comprising the following steps:

[0035]Step 1, dissolve PCL and PLLA with a mass ratio of 1:1 in a mixed solvent of dichloromethane and N,N-dimethylamide (the volume ratio of dichloromethane and N,N-dimethylamide is 5:1 ), obtain the PCL / PLLA solution of 15% by mass percent;

[0036] Step 2, put the PCL / PLLA solution into a high-voltage electrospinning device for electrospinning. The technical parameters of the electrospinning are: spinning voltage 15kv, needle distance 25cm, drum speed 1000r / min, and the pump moves The speed is 100 μm / s to obtain PCL / PLLA fiber membrane;

[0037] Step 3, rinse the PCL / PLLA fiber membrane with alcohol and place it in a vacuum oven at a preset temperature of 40°C to dry thoroughly, and then place it in PBS buffer solution with esterase added for degradation. The concentration of esterase is 0.01mg / ml, the degradation temperature wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com