Shale in-situ gas-bearing parameter determination method and system based on carbon isotope fractionation

A carbon isotope and parameter determination technology, applied in molecular entity identification, special data processing applications, design optimization/simulation, etc., can solve the problems of lack of quantitative models, staying in qualitative understanding and semi-quantitative analysis, limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

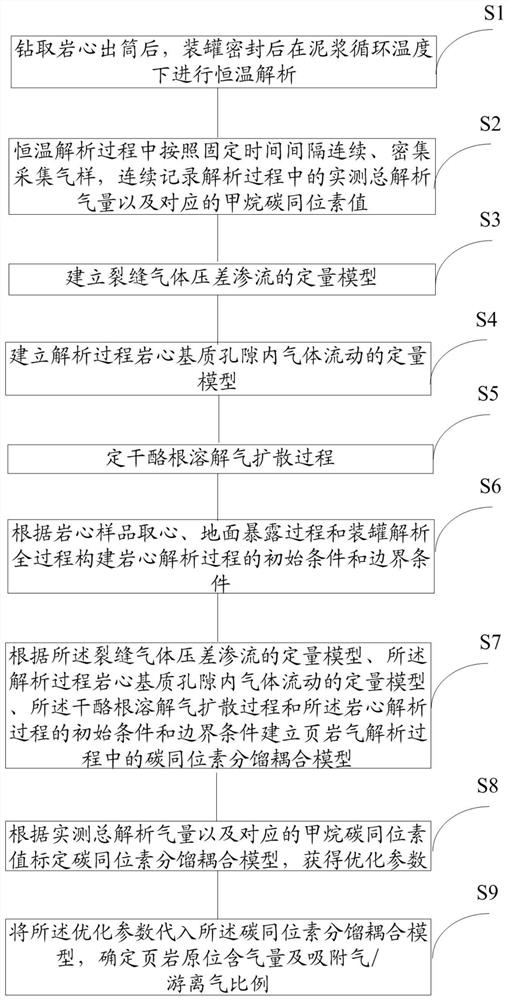

[0074] Such as figure 1 As shown, the present invention provides a method for determining in-situ gas-bearing parameters of shale based on carbon isotope fractionation, the method comprising:

[0075] Step S1: After the core is drilled out of the cylinder, it is sealed in a tank and then analyzed at a constant temperature at the mud circulation temperature.

[0076] Step S2: Continuously and densely collect gas samples at fixed time intervals during the constant temperature analysis process, and continuously record the measured total gas volume and corresponding methane carbon isotope values during the analysis process.

[0077] Step S3: Establish a quantitative model of gas pressure difference seepage in fractures.

[0078] Step S4: Establish a quantitative model of gas flow in the pores of the core matrix during the analysis process.

[0079] Step S5: Determine the diffusion process of kerogen dissolved gas.

[0080] Step S6: Construct the initial conditions and boundar...

Embodiment 2

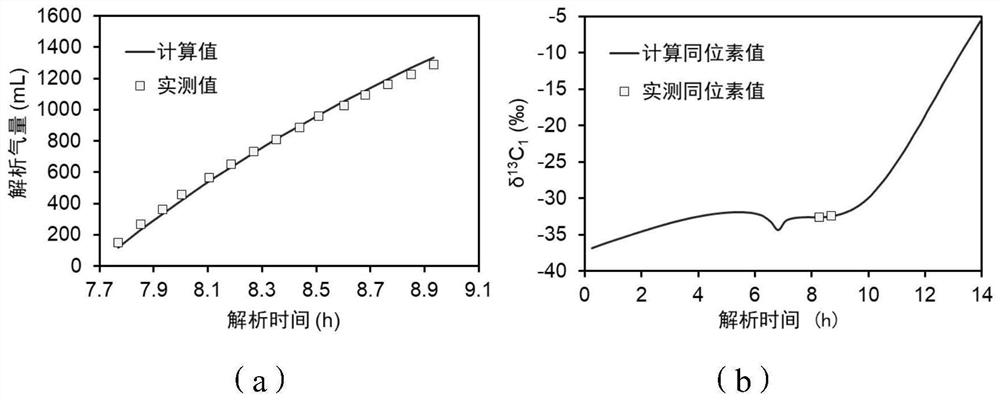

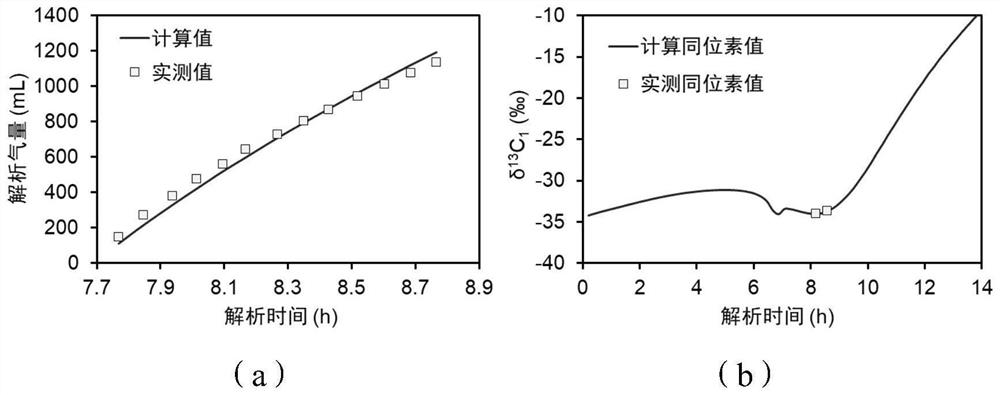

[0153] Take four shale drilling cores from marine Wufeng Formation-Longmaxi Formation in southern my country as an example:

[0154] Step 1: After cleaning, numbering, and weighing the samples after the core comes out of the barrel, put them in tanks for analysis as soon as possible to shorten the ground exposure time, and set the temperature of the analysis tank in advance as the mud circulation temperature.

[0155] Step 2: Before the analysis of core canning, the system records the key parameters required by the model (see Table 1).

[0156] Table 1 Record table of key parameters of shale core field analysis

[0157]

[0158]

[0159] Step 3: Continuously and intensively collect gas samples during the constant temperature analysis process, record the analysis time, the measured total analysis gas volume and the corresponding methane carbon isotope value during the analysis process (see Table 2).

[0160] Table 2 On-site analytical data of shale cores

[0161]

[...

Embodiment approach

[0175] As an implementation manner, the second quantitative model building module described in the present invention specifically includes:

[0176] The mass balance ratio determining unit is used for determining the mass balance ratio.

[0177] The first ratio determination unit is used to determine 12 CH 4 The ratio of the adsorption rate constant to the desorption rate constant.

[0178] The second ratio determination unit is used to determine 13 CH 4 The ratio of the adsorption rate constant to the desorption rate constant.

[0179] The first quantitative model determining unit is used for determining the mass balance ratio, the 12 CH 4 The ratio of the adsorption rate constant to the desorption rate constant and the 13 CH4 The ratio of the adsorption rate constant to the desorption rate constant was used to establish a quantitative model of the gas flow in the pores of the core matrix during the desorption process.

[0180] As an embodiment, the carbon isotope fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com