Lithium metal negative electrode, preparation method thereof and lithium-ion battery

A lithium metal negative electrode and lithium ion battery technology, applied in the field of lithium metal negative electrodes, can solve the problems of hindering lithium ion migration, capacity attenuation, and coulombic efficiency reduction, so as to improve cycle stability and safety, inhibit growth, and promote electrodeposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

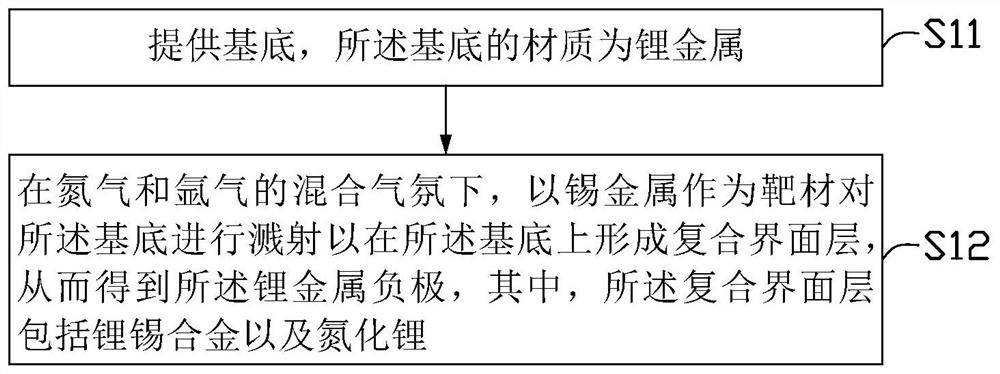

[0027] see figure 1 , a preferred embodiment of the present invention also provides a method for preparing the lithium metal negative electrode, comprising the following steps:

[0028] In step S11, a substrate is provided, and the material of the substrate is lithium metal.

[0029] Step S12 , under a mixed atmosphere of nitrogen and argon, sputtering the substrate with tin metal as a target to form a composite interface layer on the substrate, thereby obtaining the lithium metal negative electrode.

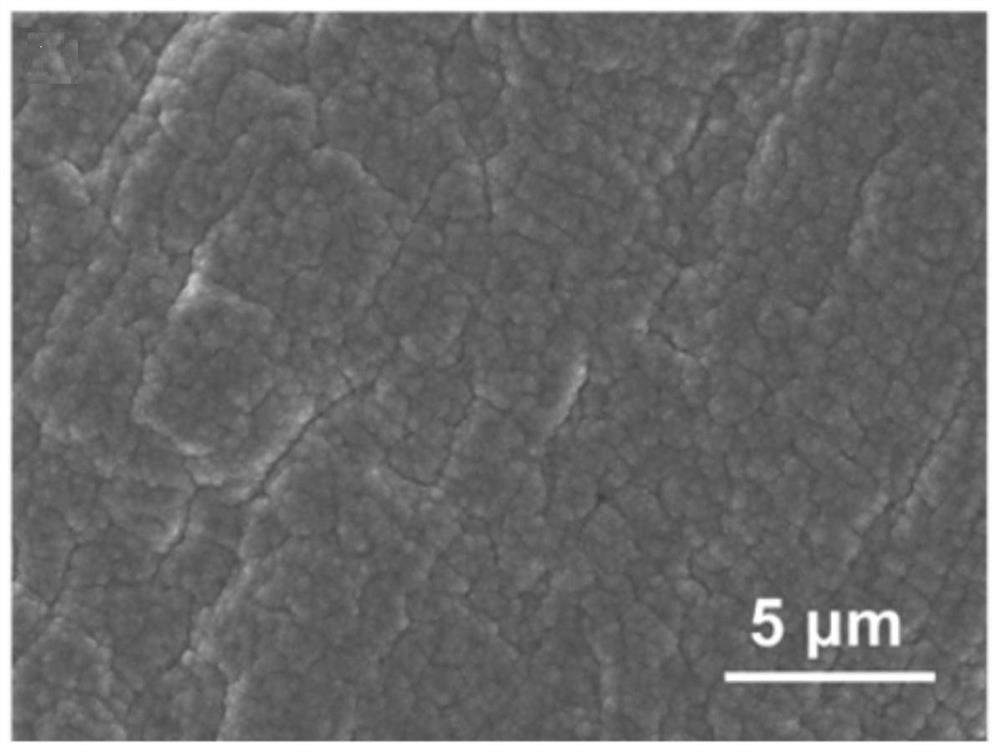

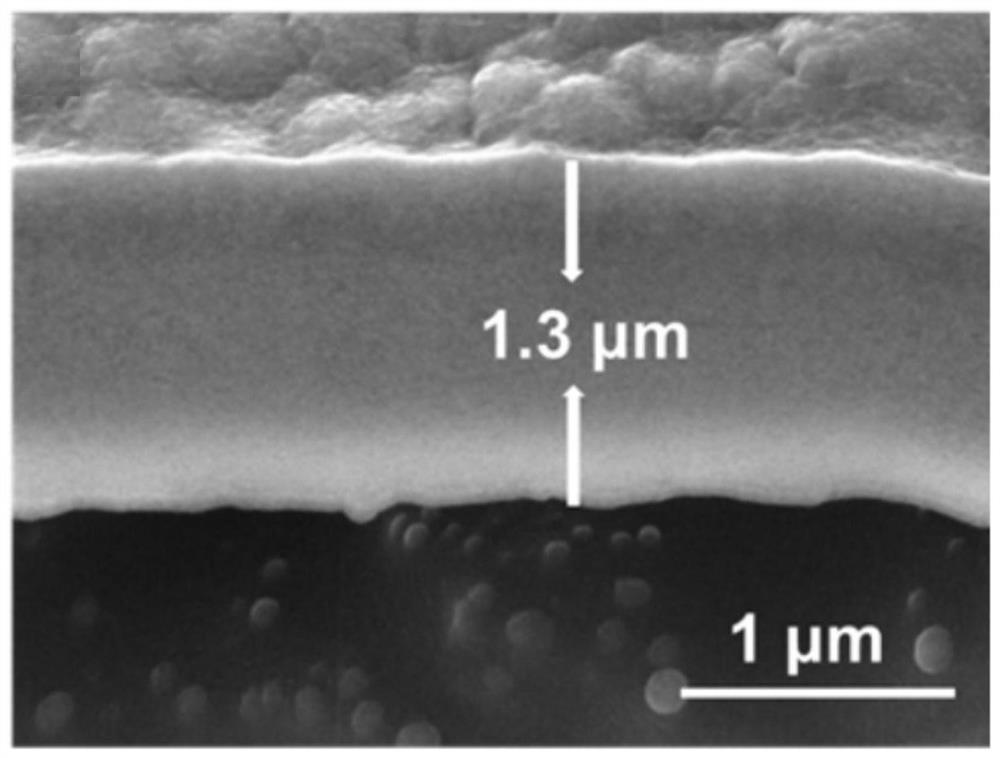

[0030] Wherein, the lithium metal negative electrode includes a substrate and a composite interfacial layer deposited on the substrate. The substrate is lithium foil, and the composite interface layer includes lithium tin alloy and lithium nitride.

[0031] During sputtering, nitrogen gas reacts with the substrate to form the lithium nitride. At the same time, during the sputtering process, argon gas collides with electrons and ionizes into argon ions, and the argon ions bomb...

Embodiment 1

[0042] In the first step, lithium metal sheet and tin metal are provided.

[0043] In the second step, magnetron sputtering is performed on the lithium metal sheet with tin metal as a target under a mixed atmosphere of nitrogen and argon to obtain a lithium metal negative electrode. Among them, the vacuum degree of the chamber before sputtering is set to 10 -4Pa, the volume ratio flow of nitrogen and argon in the sputtering process is set to 1:1, the total gas flow is set to 80sccm, the power of magnetron sputtering is set to 80W, the air pressure is set to 4Pa, and the time of magnetron sputtering is set to 20min.

[0044] Assemble the battery:

[0045] The lithium metal negative electrode prepared in Example 1 was assembled into a Li-Li symmetrical battery in an argon-protected glove box. Among them, the separator is PP, and the electrolyte is 1.0M lithium bistrifluoromethanesulfonylimide (LiTFSI) dissolved in 1,3-dioxolane (DOL) and ethylene glycol at a volume ratio of 1...

Embodiment 2

[0047] The preparation method of the lithium metal negative electrode in this example is the same as the preparation method in Example 1.

[0048] Assemble the battery:

[0049] The lithium metal negative electrode prepared in Example 2 and lithium iron phosphate (LiFePO 4 ) positive electrode assembly full battery, electrolyte and additives are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com