Positive electrode sheet capable of discharging at high rate, and lithium ion battery comprising positive electrode sheet

A technology of positive electrode sheet and positive current collector, applied in the direction of electrode current collector coating, positive electrode, battery electrode, etc., can solve the problems of cell failure safety, prone to side reactions, large contact area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Prepare the positive electrode active material slurry, the first positive electrode active material (polycrystalline ternary 523 material) accounting for 93% by mass, the conductive agent (conductive carbon black) accounting for 4% by mass, and the binder accounting for 3% by mass (Polyvinylidene fluoride) is mixed with NMP to prepare a slurry 1 with a solid content of 65-70wt% and a viscosity of 5500-6000mPa·s;

[0072] The second positive electrode active material (single crystal ternary 811 material) accounting for 93% by mass, the conductive agent (conductive carbon black) accounting for 4% by mass, and the binder (polyvinylidene fluoride) accounting for 3% by mass Mixed with NMP to prepare slurry 2 with a solid content of 65-70wt% and a viscosity of 5500-6000mPa·s.

[0073] Using a double-layer coating machine, the slurry 1 and the slurry 2 are coated on both sides of the positive electrode current collector, and the first positive electrode active material layer f...

Embodiment 2-5

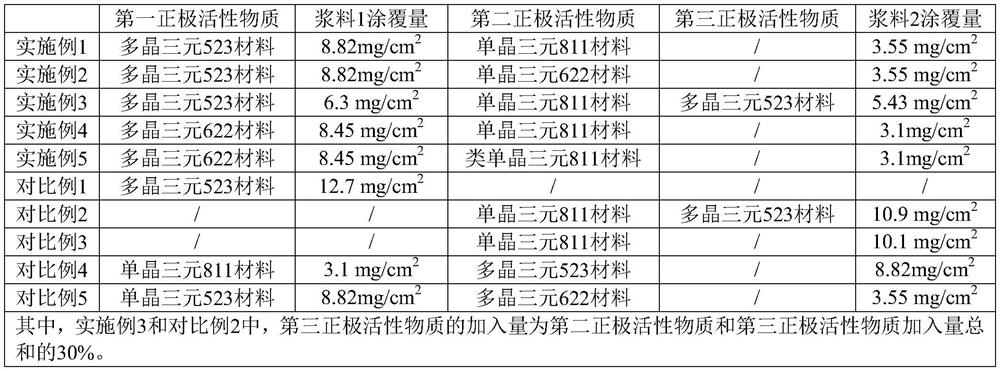

[0077] Others are the same as in Example 1, except that the selection of the positive electrode active material is different, and the coating amount is different, as shown in Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com