Forceps channel tube of medical flexible endoscope and preparation method of forceps channel tube

A technology of endoscopes and hoses, applied in the field of medical devices, can solve problems such as rough surfaces, many production personnel, and difficult cleaning and disinfection, and achieve the effects of high anti-deformation strength, low raw material costs, and optimal chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

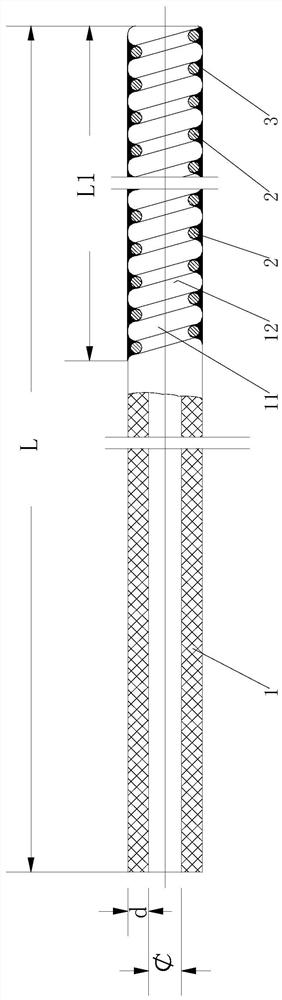

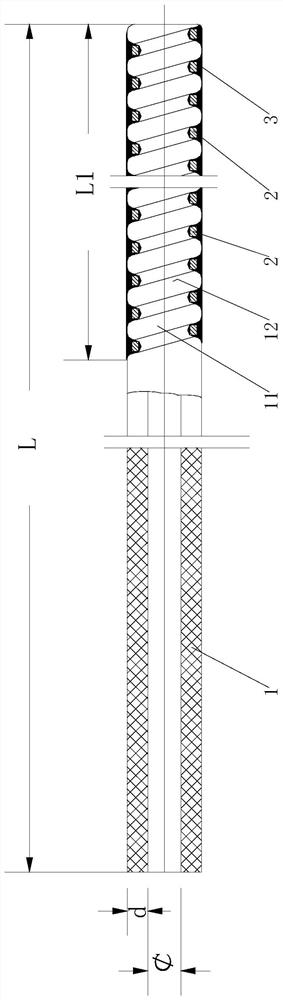

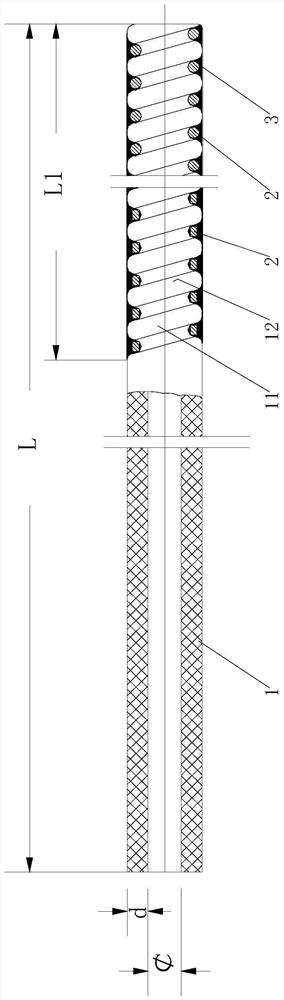

[0039] like figure 1 , 2 , 3, 4, 5, 6, and 7, a clamp tube of a medical flexible endoscope includes a polytetrafluoroethylene hose 1 and a spring 2, and one end of the polytetrafluoroethylene hose 1 has The bending portion 11 integrated with it has a helical spring groove 12 on the outer wall of the bending portion 11 , and the spring 2 is arranged in the spring groove 12 of the bending portion 11 . The spring combination section of the polytetrafluoroethylene hose equipped with the coil spring part has a better effect of invariant bending. When it is bent to the maximum bending angle of 260 degrees, the tolerance of its roundness is ≤0.05mm. Because biopsy forceps are used for The outer diameter of the instrument in the endoscope channel is about 0.2mm smaller than the size of the tube hole of the clamp channel, which can fully meet the requirements of the relevant endoscopic instruments to enter the human body smoothly through the aperture of the channel tube for biopsy or ...

Embodiment 2

[0048] like figure 1 , 2 , 3, 4, 5, 6, and 7, a preparation method of a clamp channel tube of a medical flexible endoscope, its specific preparation steps are:

[0049] 1. Material selection:

[0050] Select the polytetrafluoroethylene hose that meets the technical parameter requirements as the raw material for preparing the clamp pipe body, the fluororubber adhesive, and the stainless steel wire as the raw material for preparing the helical compression spring. The inner diameter of the polytetrafluoroethylene hose is The wall thickness d is 0.13mm-0.55mm, and the total length L is 380mm-1850mm;

[0051] 2. The processing method of the spring groove at one end of the PTFE hose:

[0052] Use a lathe to machine a spring groove that meets the requirements of the drawings at one end of the polytetrafluoroethylene hose. The length L1 of the spring groove is 90mm to 200mm, and the tooth angle α of the spring groove is 30° to 60°. The pitch P of the spring groove is 0.8 mm to 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com