Construction waste environment-friendly ship loader

A technology for construction waste and ship loader, which is applied in the direction of cleaning device, transportation and packaging, loading/unloading, etc., can solve the problems of long time-consuming for climbing, does not meet environmental protection requirements, and the ship loader cannot move, and achieves a compact structure. , Small footprint, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

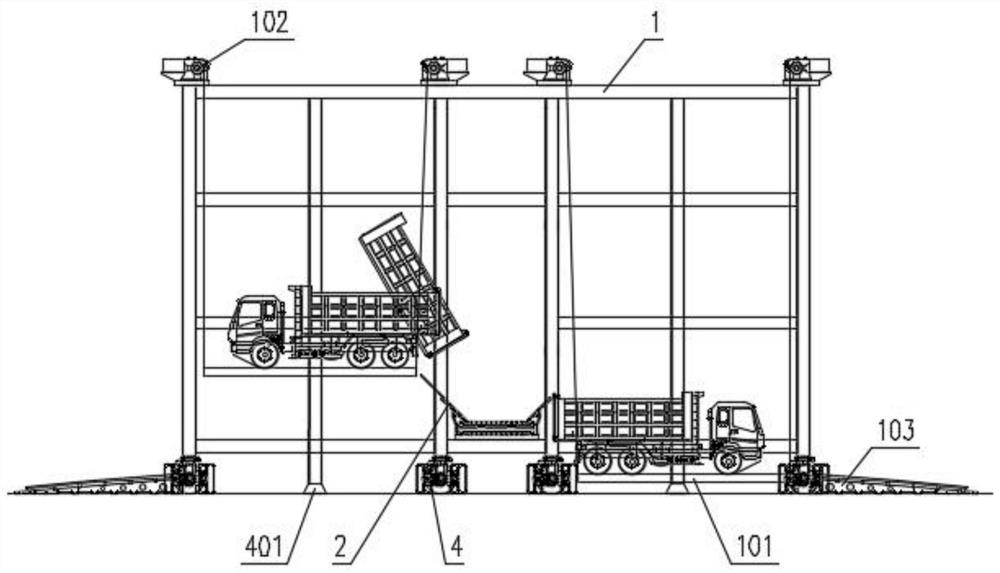

[0039] see figure 1 , an environmentally friendly construction waste loading machine, including a main frame 1, a muck truck lifting system is installed inside the main frame 1, and the muck truck lifting system includes a pair of lifting platforms 101, and the lifting platform 101 slides with the main frame 1 through guide rails connection, the top of the main frame 1 is fixedly installed with a plurality of first hoisting devices 102, the first hoisting devices 102 are connected with first steel wire ropes, and the end of the first steel wire ropes away from the first hoisting device 102 and the lifting platform 101 at the corresponding position The four corners of the upper end of the lifting platform 101 are equipped with lifting lugs, and the end of the first wire rope away from the first hoisting device 102 is fixedly connected with the lifting lugs through mechanisms such as pin shafts and locking nose brackets. The first hoisting device 102 and the first hoisting device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com