Production system of low-chlorine potassium sulfate

A production system, technology of potassium sulfate, applied in the field of production system of low-chlorine potassium sulfate, can solve problems such as increasing costs, and achieve the effects of saving production costs, reducing consumption, and fully reacting raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

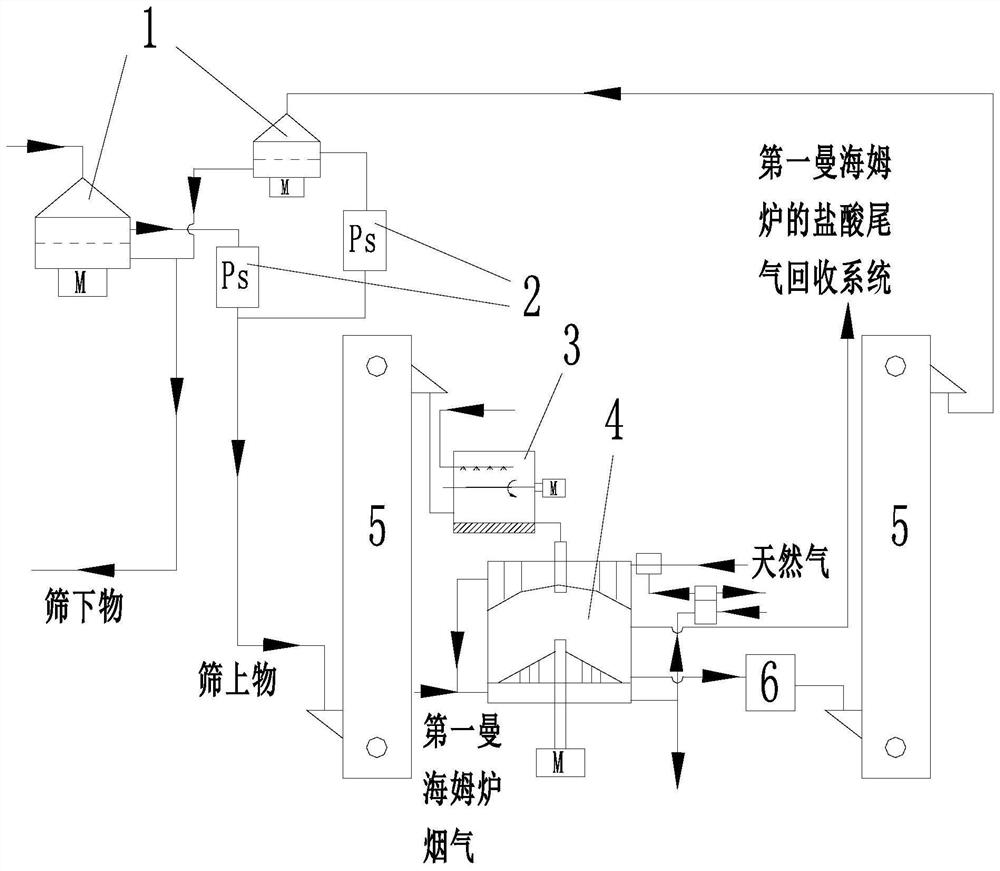

[0043] Such as figure 1 As shown, the production system of the low chloride potassium sulfate described in the present embodiment comprises a first Mannheim furnace 1, a first screening device, a first crushing device 2, a mixing device 3 and a second Mannheim furnace 4. The potassium sulfate product in the first Mannheim furnace 1 enters the first screening device for screening, and the screened oversize enters the first crushing device 2, and the pulverized oversize is mixed with concentrated sulfuric acid in the mixing device 3, The mixture enters the second Mannheim furnace 4 for heating reaction to obtain potassium sulfate perchlorate.

[0044] The first Mannheim furnace 1 includes four sets, and each first Mannheim furnace 1 is respectively connected with a first screening device, and each first screening device is connected with a first crushing device 2, and each first The crushing devices 2 communicate with the mixing device 3 respectively.

[0045] In another solut...

Embodiment 2

[0056] Such as figure 1 As shown, what is described in this embodiment is the further limitation of the above-mentioned embodiment one. The mixing device 3 has a stirring device and a spraying device. The concentrated sulfuric acid enters the mixing device 3 in a mist form through the spraying device. Mix with sieve. Because the consumption of the concentrated sulfuric acid is very little compared with the solid granular sieve, the concentrated sulfuric acid is sprayed into the mixing device 3 in the form of spraying, so that the mist droplets formed by the concentrated sulfuric acid can be wrapped on the surface of the solid particles, and after stirring The mixing of the two is more uniform, which is beneficial to the subsequent reaction of the second Mannheim furnace 4 to proceed more fully.

[0057] In this embodiment, a mixing device with a stirring device and a spraying device is used to spray concentrated sulfuric acid into the oversize material in the form of a spray,...

Embodiment 3

[0059] What is described in this embodiment is a further limitation of the above-mentioned embodiment one, the combustion chamber of the first Mannheim furnace is provided with a flue gas outlet, the second Mannheim furnace is provided with a flue gas inlet, and the first Mannheim furnace is provided with a flue gas inlet. The flue gas outlet of the Heim furnace is connected with the flue gas inlet of the second Mannheim furnace through a pipeline. When using the Mannheim method to produce potassium sulfate in the existing process, since the raw material sulfuric acid is liquid, it will corrode the hearth of the Mannheim furnace and easily cause acid leakage. Generally, the flue gas is not passed into the bottom of the furnace to reuse the heat energy. In this embodiment, the concentrated sulfuric acid and the oversize are mixed in the mixing device to become solid, and then enter the second Mannheim furnace. There is no liquid concentrated sulfuric acid, and there is no corros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com