Composite coated all-solid-state battery cathode material and preparation method thereof and all-solid-state battery

A technology of all-solid-state batteries and positive electrode materials, applied in battery electrodes, electrolyte storage battery manufacturing, secondary batteries, etc., can solve the problems of low ion conductivity, achieve the effect of improving rate performance and cycle performance, and speeding up the process of large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a positive electrode material coated with LATP&CNT composite, the preparation of which includes the following steps:

[0024] Fluidized bed preparation of coated positive electrode:

[0025] (1) Take by weighing 10kg NCM712 cathode material and add in the fluidized bed cavity;

[0026] (2) Mix 25.3g of lithium nitrate, 39.3g of aluminum nitrate nonahydrate, 142.5g of tetrabutyl titanate, 143.1g of triethyl phosphate, and 1L of ethanol, and then add 10kg of CNT slurry with a solid content of 0.4%. , through the form of a peristaltic pump, add gas atomization, add gas into the cavity at a speed of 4g / min, the cavity speed is 300, the gas supply temperature is 120°C, and the exhaust temperature is 40°C;

[0027] (3) The powder material was sintered at 500° C. for 4 hours to obtain a composite-coated cathode material of LATP & CNT.

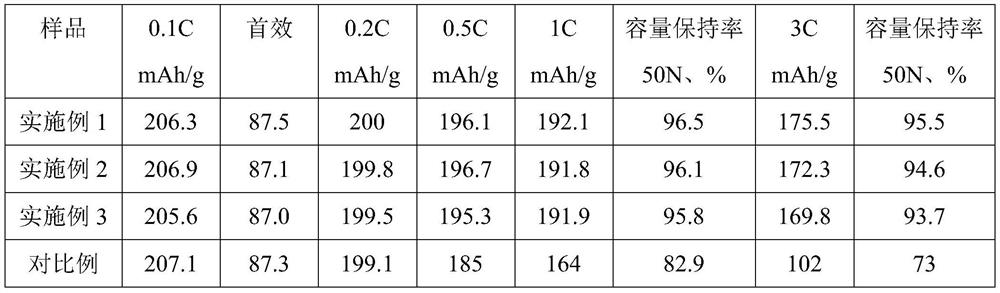

[0028] Prepare a solid-state battery with the above-mentioned coated and modified composite positive electrode mate...

Embodiment 2

[0032] This embodiment provides an all-solid-state battery using LLTO&CNT-coated positive electrode materials and its manufacturing method. The preparation includes the following steps:

[0033] Fluidized bed preparation of coated positive electrode:

[0034] (1) Take by weighing 10kg NCM712 cathode material and add in the fluidized bed cavity;

[0035] (2) Mix and stir 64.4g of lanthanum nitrate, 10.3g of lithium nitrate, 101.3g of tetrabutyl titanate, and 10L of ethylene glycol monomethyl ether, and then add 10kg of CNT slurry with a solid content of 0.4%. Form, add gas to atomize, add to the cavity at a speed of 4g / min, the cavity speed is 300, the gas supply temperature is 120°C, and the exhaust temperature is 40°C;

[0036] (3) Heat-preserve and sinter the powder material at 550 degrees for 6 hours to obtain a composite coated positive electrode material.

[0037] Prepare a solid-state battery with the above-mentioned coated and modified positive electrode material, the...

Embodiment 3

[0041]This embodiment provides an all-solid-state battery using a positive electrode material coated with LATP&CNT and its manufacturing method. The preparation includes the following steps:

[0042] Fluidized bed preparation of coated positive electrode:

[0043] (1) Weigh 10kg NCM712 positive electrode material, LATP powder 50g, CNT powder 50g and mix fully;

[0044] (2) The mixed powder material is sintered at 500°C for 6 hours to obtain a composite coated positive electrode material.

[0045] Prepare a solid-state battery with the above-mentioned coated and modified positive electrode material, the specific method is:

[0046] (1) The LATP ceramic powder is sand-milled to obtain 300nm particles, and the LATP particles are dissolved in isopropanol dispersion, and then coated on both sides of the 12-micron PP diaphragm through the ceramic coating process, and the coating thickness is prepared as follows: 2 micron LATP functional ionic membrane.

[0047] (2) Using the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com