Waste incineration fly ash heavy metal inorganic composite stabilizing agent and stabilizing and curing method thereof

A technology of waste incineration fly ash and inorganic compounding, which is applied to the protection device for preventing harmful chemicals, etc., can solve the problems of complex compound prescription, high cost of harmless treatment, and large amount of compound medicine, and achieves good application prospects, Easy to store for a long time, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

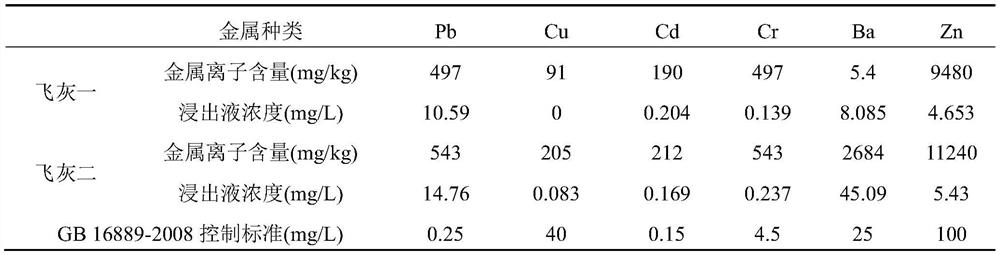

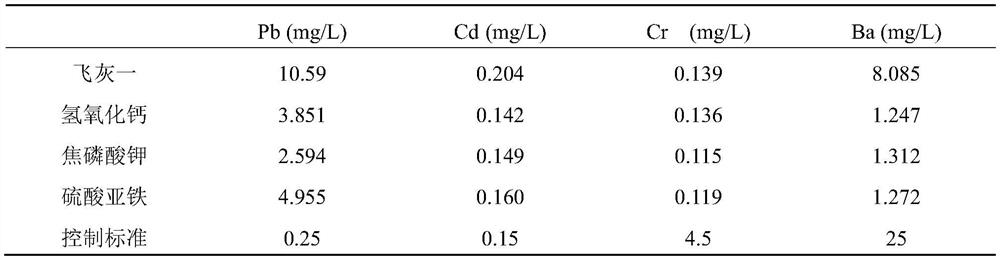

[0032] The object of treatment is fly ash 1. The leaching shows that the heavy metals lead (10.59mg / L) and cadmium (0.204mg / L) exceed the standard, and the lead seriously exceeds the standard.

[0033] Take 100 parts of waste incineration fly ash and add 6 parts of heavy metal inorganic composite stabilizer (calcium hydroxide: sodium dihydrogen phosphate: ferrous sulfate = 1:1:1), stir and mix evenly, add 70 parts of water and fully stir to obtain a slurry Shaped mixture, natural conservation for 5 days. The leaching concentrations of heavy metals lead and cadmium were 0.236mg / L and 0.142mg / L, respectively, both of which were lower than the entry control standards for domestic waste landfills.

Embodiment 2

[0035] The object of treatment is fly ash 1. The leaching shows that the heavy metals lead (10.59mg / L) and cadmium (0.204mg / L) exceed the standard, and the lead seriously exceeds the standard.

[0036] Take 100 parts of waste incineration fly ash and add 4 parts of heavy metal inorganic composite stabilizer (calcium hydroxide: sodium dihydrogen phosphate: ferrous sulfate = 2:1:1), stir and mix evenly, add 70 parts of water and fully stir to obtain a slurry To form the mixture, add 10 parts of cement, stir and mix evenly, and then maintain it naturally for 5 days. The leaching concentrations of heavy metals lead and cadmium were 0.211mg / L and 0.097mg / L, respectively, both of which were lower than the entry control standards for domestic waste landfills.

Embodiment 3

[0038] The object of treatment is fly ash 1. The leaching shows that the heavy metals lead (10.59mg / L) and cadmium (0.204mg / L) exceed the standard, and the lead seriously exceeds the standard.

[0039] Take 100 parts of waste incineration fly ash and add 8 parts of heavy metal inorganic composite stabilizer (bentonite: disodium hydrogen phosphate = 3:1), stir and mix evenly, add 100 parts of water and stir thoroughly to obtain a slurry mixture, and naturally cure for 5 days. The leaching concentrations of heavy metals lead and cadmium were 0.142mg / L and 0.109mg / L, respectively, both of which were lower than the entry control standards for domestic waste landfills.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com