A device and method for simultaneous reduction of manganese-containing iron minerals by biomass pyrolysis

A biomass pyrolysis and biomass technology, which is applied in the fields of biofuel, process efficiency improvement, coke oven, etc., can solve the problems of high heat loss, narrow application area, complicated equipment connection, etc., and achieve high reduction efficiency and material saving. and time cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

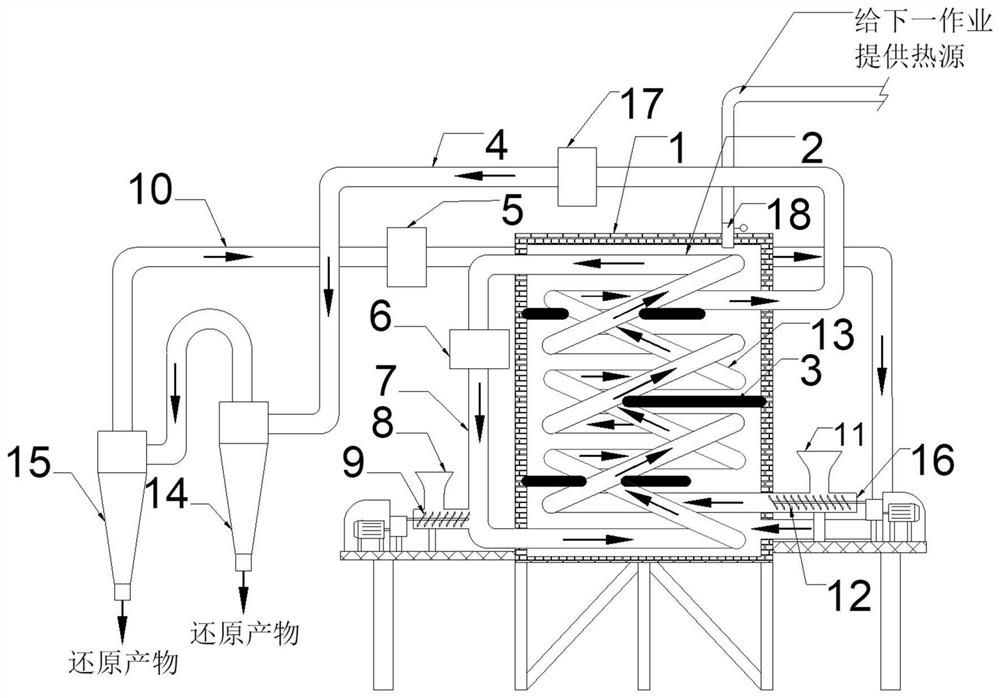

[0054] like figure 1 As shown, a device for synchronous reduction of manganese-containing iron minerals by biomass pyrolysis, the device includes a furnace body 1, a pyrolysis pipe 2, a discharge pipe 4, a vertical circulation pipe 7, a material circulation pipe 10, a pyrolysis Reduction pipe 13, biomass preheating pipe 16;

[0055] Pyrolysis pipe 2 and pyrolysis reduction pipe 13 are arranged inside described furnace body 1, and pyrolysis reduction pipe 13 is sleeved in pyrolysis pipe 2; The inlet of pyrolysis pipe 2 is connected with the outlet of biomass preheating pipe 16, and the thermal The outlet of the decomposition pipe 2 is connected with the inlet of the pyrolysis induced draft fan 6, the outlet of the pyrolysis induced draft fan 6 is connected with the inlet of the vertical circulation pipe 7, the outlet of the vertical circulation pipe 7 is connected with the inlet of the pyrolysis reduction pipe 13, and the thermal The outlet of the decomposing reduction pipe 13...

Embodiment 2

[0065] like figure 1 As shown, a device and method for synchronously reducing deep-sea manganese oxide minerals by pyrolysis of biomass. The affiliated device includes a furnace body 1, and a pyrolysis tube 2 and a pyrolysis reduction tube 13 are arranged in the inner space of the furnace body; a biomass feed port 11 is provided on the right side of the furnace body, and a biomass feed port 11 is provided at the lower end of the biomass feed port 11. The material delivery mechanism 12, the biomass delivery mechanism 12 is connected with the pyrolysis pipe 2; the pyrolysis pipe 2 is connected with the vertical circulation pipe 7 outside the furnace body, and the left side of the vertical circulation pipe 7 is connected with the mineral feed for adding deep-sea manganese oxide minerals The port 8 is connected; the pyrolysis reduction pipe 13 is connected with the discharge pipe 4, the discharge pipe 4 is connected with the first-stage cyclone separator 14, and the first-stage cy...

Embodiment 3

[0080] Adopt the device described in embodiment 1 to carry out mineral reduction, the biomass and mineral that adopt are specific as follows:

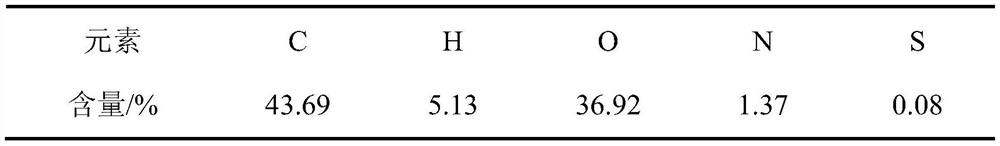

[0081] Seaweed elemental analysis result is as follows table (wt%)

[0082]

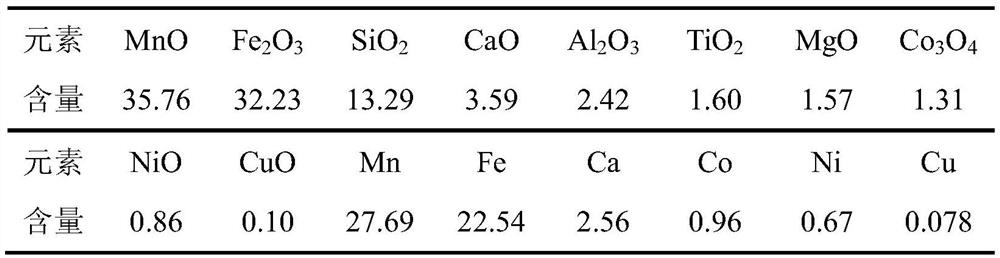

[0083] Manganese nodule chemical composition analysis result is as follows table (wt%)

[0084]

[0085] Adjust the temperature of the pyrolysis furnace to 800°C. Seaweed (particle size <50mm) is fed through the feed port of the material preheating tube. It is continuously preheated during the screw propulsion process. The preheating temperature is 400°C. After entering the pyrolysis tube of the pyrolysis reduction furnace , under the action of the induced draft fan, it moves upwards and pyrolyzes for 3 minutes at the same time. The manganese nodules (particle size <0.5mm) are mixed with the pyrolysis products of seaweed through the left side of the furnace body, and then enter the pyrolysis tube in the furnace body for roasting and reduction. 4min, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com