High-density low-crosstalk waveguide array based on micro-nano isolation structure

A technology of isolation structure and waveguide array, applied in the directions of light guides, instruments, optics, etc., can solve the problems of low emission efficiency and insufficient use of light, and achieve the effect of high product yield, transmittance and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be further described below.

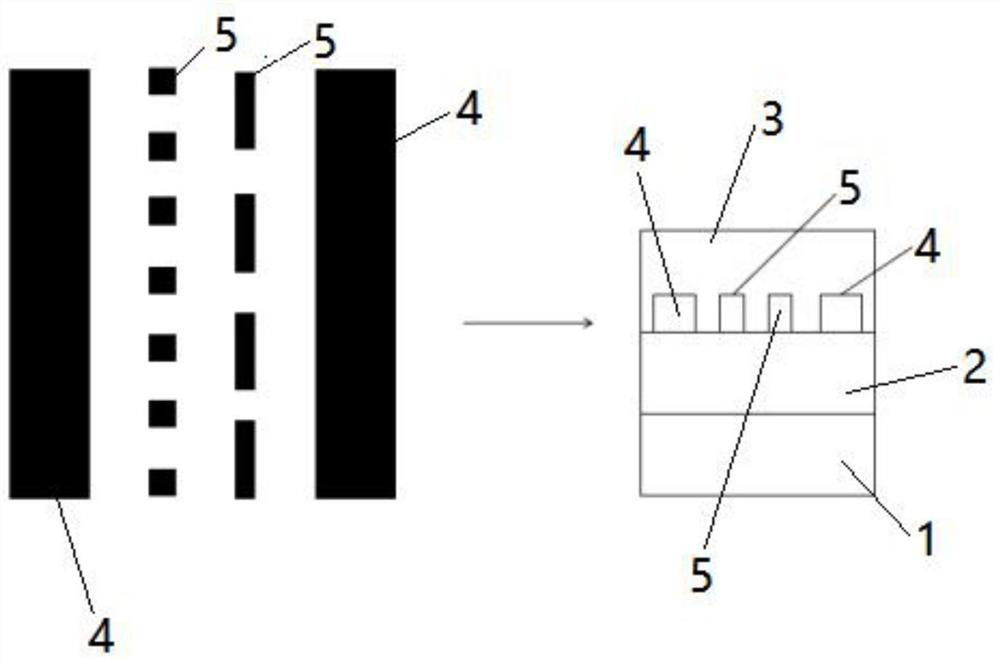

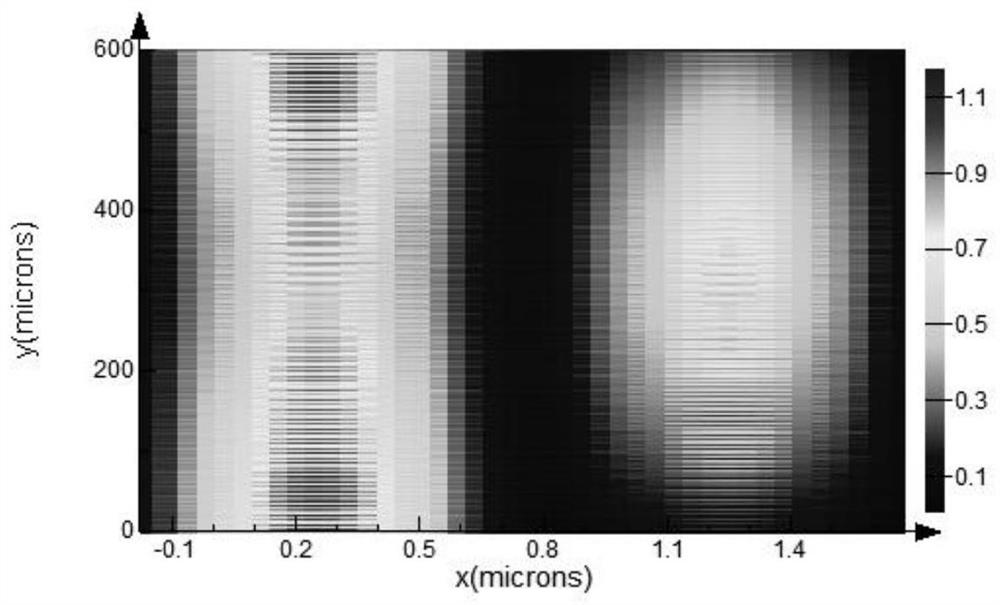

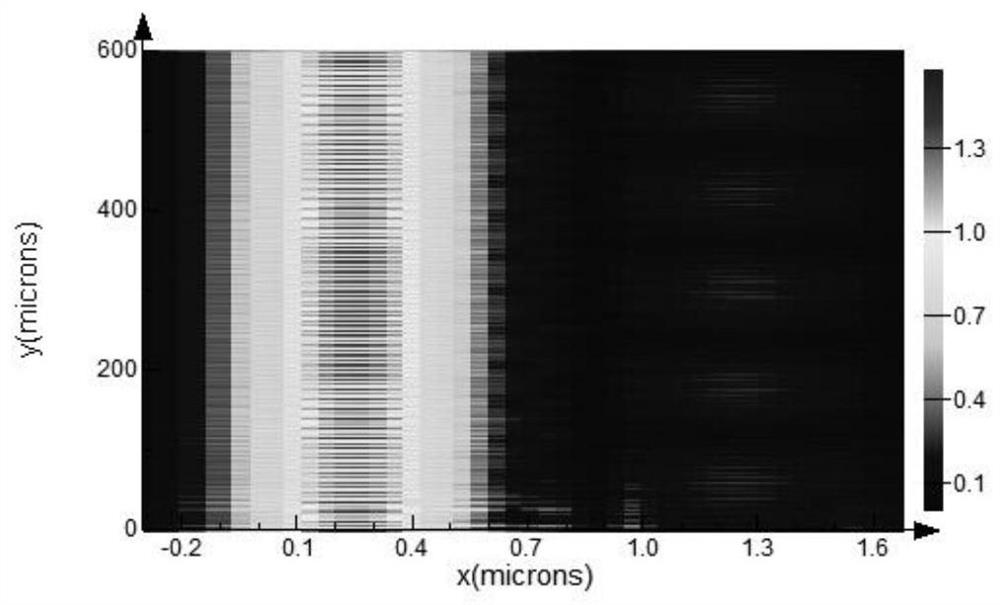

[0024] For wide waveguide designs, a large amount of coupling occurs in the straight waveguide coupling region. When designing this embodiment, if figure 1 As shown, the straight-width waveguide length is selected as 600 μm, the waveguide gap is 1 μm, and the waveguide width is 0.5 μm.

[0025] For the design of the periodic grating, two grating structures with different periods and duty ratios are added between the straight waveguides to achieve the effect of suppressing waveguide coupling. The first periodic grating structure in the middle of the wide waveguide is selected, with a period of 0.3-0.4 μm. The duty ratio is 0.3-0.4, the width is 0.12 μm, and the number of gratings is 1500-2000. The second grating structure has a period of 0.3-0.4 μm, a duty ratio of 0.5-0.8, a width of 0.12 μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com