Degradable filling composition for tooth extraction wounds and preparation method and use of degradable filling composition

A technology of filling composition and tooth extraction wound, which is applied in the field of biomedical materials for oral care, which can solve the problems of unstable tooth extraction socket, short action time, and poor plasticity, and achieve no need for pressing, small foreign body sensation, and good plasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]The degradable dental extraction wound filling composition includes the following raw materials by weight: 6g calcium stearate, 3g alginic acid / chitosan complex, 2g bioactive glass, and 6g tocopherol acetate;

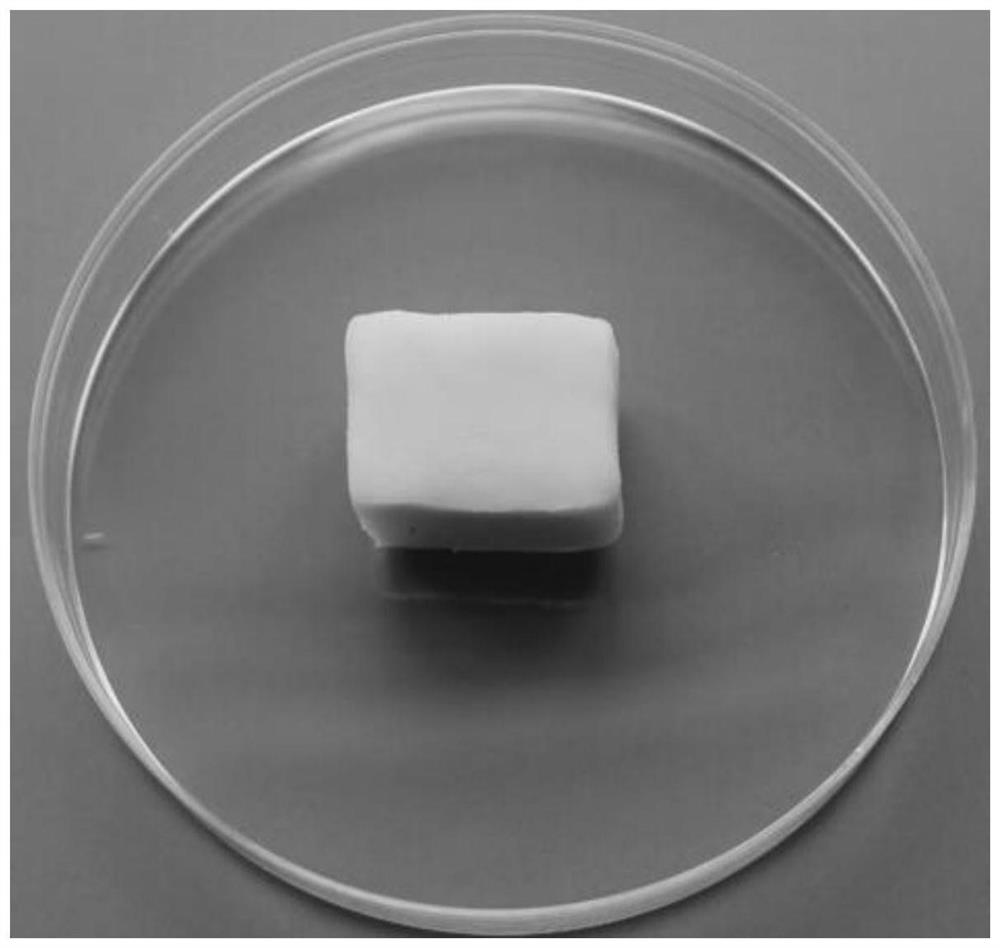

[0030]The preparation method of the degradable tooth extraction wound filling composition: weigh the components according to the formula, mechanically mix the dry solid components, and gradually add the liquid component tocopherol acetate after mixing, mix mechanically at room temperature, and treat to a uniform putty Shape, that is, a degradable tooth extraction wound filling composition is obtained. Physical imagefigure 1As shown, the degradable dental extraction wound filling composition of this embodiment can be arbitrarily shaped and deformed in the tooth socket, and can fully fill, especially the irregular tooth socket.

[0031]The preparation method of the alginic acid / chitosan complex in this embodiment is as follows: Dissolve 0.1g sodium alginate and 3.0g chitosan in...

Embodiment 2

[0034]The degradable dental extraction wound filling composition includes the following raw materials by weight: 5g calcium stearate, 4g alginic acid / chitosan complex, 2g bioactive glass, 5g tocopherol acetate, 1g poloxamer (Pluronic L35);

[0035]The preparation method of the degradable tooth extraction wound filling composition is the same as in Example 1.

[0036]The preparation method of the alginic acid / chitosan complex in this example is the same as that of Example 1.

[0037]The bioactive glass in this example is the same as in example 1.

[0038]The physical characteristics of the composition obtained in this example are similar to those of the composition of Example 1, but the water resistance of Example 1 is weakened, the swelling time is shortened, and the viscosity of the composition of this example is increased.

[0039]The retention time of the composition in the extraction socket can be controlled by adjusting the amount of poloxamer in the formula. Poloxamer is used to adjust the s...

Embodiment 3

[0042]The degradable dental extraction wound filling composition includes the following raw materials by weight: 4g calcium stearate, 6g alginic acid / chitosan complex, 1g bioactive glass, and 6g tocopherol acetate;

[0043]The preparation method of the degradable dental extraction wound filling composition is the same as in Example 1.

[0044]The preparation method of the alginic acid / chitosan complex in this embodiment is as follows: prepare 20 mL of sodium alginate-acetic acid aqueous solution with a concentration of 0.3% pH=5 and 5 mL of chitosan-acetic acid aqueous solution with a concentration of 0.15% pH=5. Slowly drip the chitosan-acetic acid aqueous solution into the sodium alginate-acetic acid aqueous solution under ultrasonic conditions, and after stirring for 30 minutes, the sodium alginate / chitosan gel microspheres were precipitated, and the gel microspheres were obtained by centrifugation for 20 minutes. Glue microspheres are washed with water: washed with 30%, 70% and 100% e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com