Waterproof concrete and preparation method thereof

A technology of waterproof concrete and cement, which is applied in the field of concrete processing and can solve problems such as poor waterproof ability of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A waterproof concrete, comprising the following materials in corresponding parts by weight: 160 parts of cement, 20 parts of sodium silicate, 35 parts of fly ash, 10 parts of calcium carbonate, 25 parts of sand, 1 part of activator, 1 part of binder, 5 parts of Parts of basalt fiber, 8 parts of composite filler, 100 parts of water.

[0030] The activator is sodium lignosulfonate; the binder is sodium carboxymethyl cellulose.

[0031] The preparation method of described composite filler comprises the steps:

[0032] 1) Mix illite powder, titanium sponge, alumina, ferrocene, lanthanum nitrate, and sodium pyrophosphate together, stir them evenly, and put them into the reaction kettle;

[0033] 2) Vacuumize the inside of the reaction kettle, then heat up the reaction process, and take out the materials for later use;

[0034] 3) After cooling the material obtained in step 2) to normal temperature naturally.

[0035] When the illite powder, titanium sponge, alumina, ferro...

Embodiment 2

[0042] A waterproof concrete, comprising the following materials in corresponding parts by weight: 170 parts of cement, 23 parts of sodium silicate, 40 parts of fly ash, 13 parts of calcium carbonate, 28 parts of sand, 1.3 parts of activator, 2 parts of binder, 7 parts of Parts of basalt fiber, 10 parts of composite filler, 105 parts of water.

[0043] The activator is sodium lignosulfonate; the binder is sodium carboxymethyl cellulose.

[0044] The preparation method of described composite filler comprises the steps:

[0045] 1) Mix illite powder, titanium sponge, alumina, ferrocene, lanthanum nitrate, and sodium pyrophosphate together, stir them evenly, and put them into the reaction kettle;

[0046] 2) Vacuumize the inside of the reaction kettle, then heat up the reaction process, and take out the materials for later use;

[0047] 3) After cooling the material obtained in step 2) to normal temperature naturally.

[0048] When the illite powder, titanium sponge, alumina, fe...

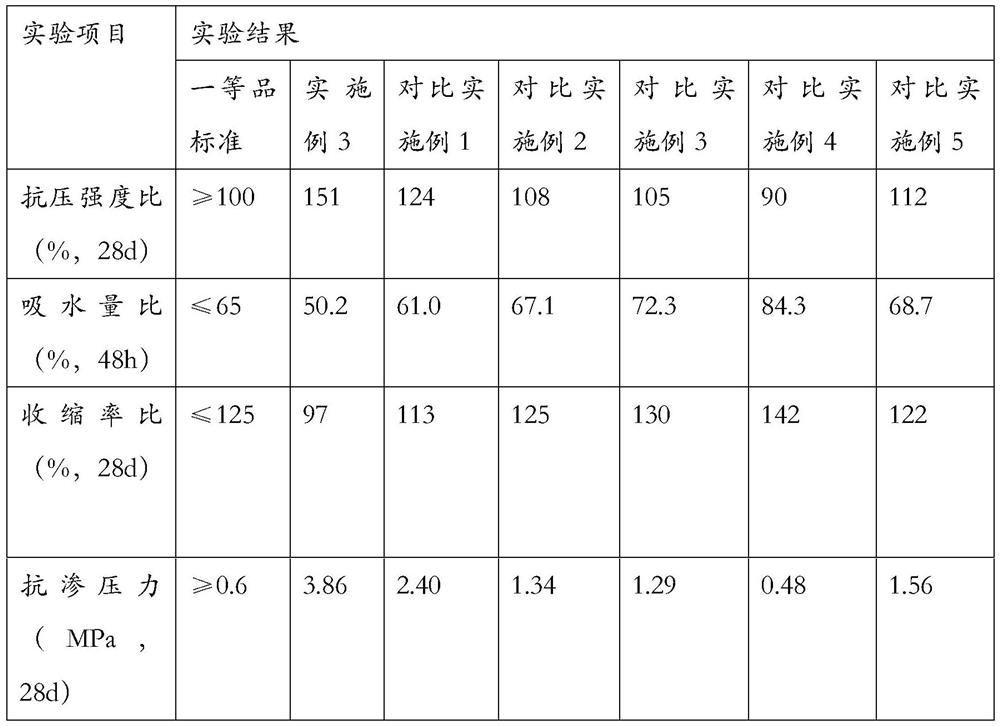

Embodiment 3

[0055] A waterproof concrete, comprising the following materials in corresponding parts by weight: 180 parts of cement, 25 parts of sodium silicate, 45 parts of fly ash, 15 parts of calcium carbonate, 30 parts of sand, 1.5 parts of activator, 3 parts of binder, 8 parts of Parts of basalt fiber, 12 parts of composite filler, 110 parts of water.

[0056] The activator is sodium lignosulfonate; the binder is sodium carboxymethyl cellulose.

[0057] The preparation method of described composite filler comprises the steps:

[0058] 1) Mix illite powder, titanium sponge, alumina, ferrocene, lanthanum nitrate, and sodium pyrophosphate together, stir them evenly, and put them into the reaction kettle;

[0059] 2) Vacuumize the inside of the reaction kettle, then heat up the reaction process, and take out the materials for later use;

[0060] 3) After cooling the material obtained in step 2) to normal temperature naturally.

[0061] The corresponding weight ratio when the illite pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com