Hydroxyapatite-containing material, method for synthesizing and forming hydroxyapatite-containing material in one step and application of hydroxyapatite-containing material

A technology of calcium hydroxyphosphate and calcium phosphate salt, which is applied in the direction of chemical instruments and methods, applications, and other household appliances, and can solve problems such as low production efficiency, unstable calcium hydroxyphosphate products, and long synthesis time, and achieve no three wastes discharge , good environmental conditions and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

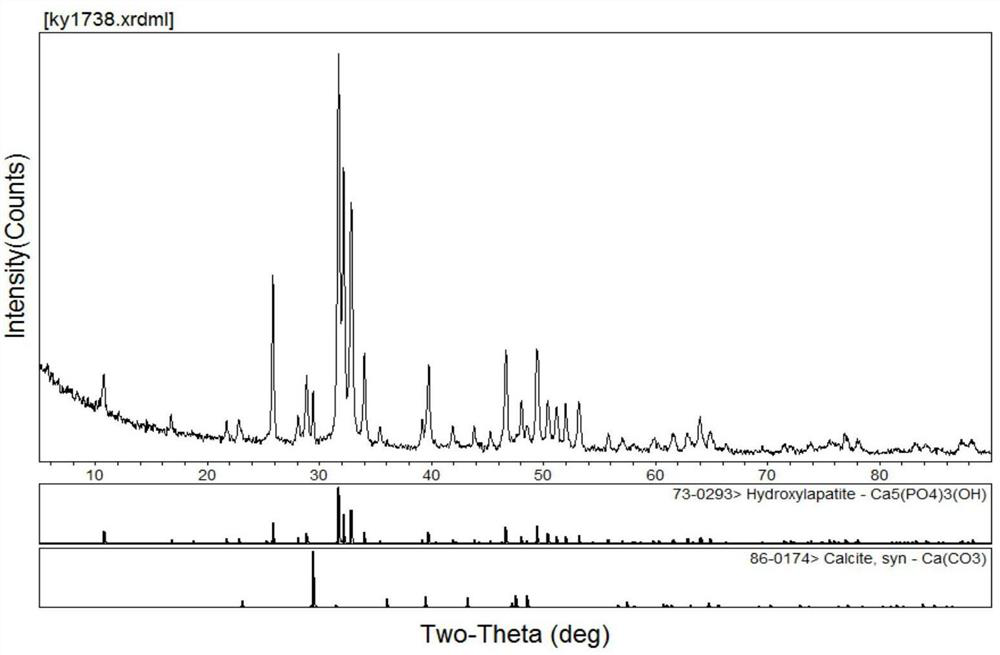

Image

Examples

Embodiment 1

[0045]This embodiment provides a preparation and molding method of a hydroxyl-containing calcium phosphate material, including the following steps:

[0046](1) Using calcium hydrogen phosphate dihydrate CaHPO4·2H2O and calcium hydroxide Ca(OH)2Mixed as raw material of mixed inorganic calcium salt, Na2HPO4Aqueous solution as a feed ingredient;

[0047]Among them, among the mixed inorganic calcium salt raw materials, calcium hydrogen phosphate dihydrate CaHPO4·2H2O and calcium hydroxide Ca(OH)2The total Ca / P ratio is 1.576; CaHPO4·2H2The average particle size D50 of O is 4-6μm, Ca(OH)2The average particle size D50 is 5-8μm;

[0048](2) Weigh 10g, 1M Na of the mixed inorganic calcium salt raw material in step (1)2HPO4Place 2.6 mL of the solution in a porcelain dish and mix, add 50 g of water under normal temperature and pressure, and stir evenly to obtain a mixed slurry. Spread the mixed slurry naturally under vibration conditions, add a small amount of water to cover the surface of the slurry,...

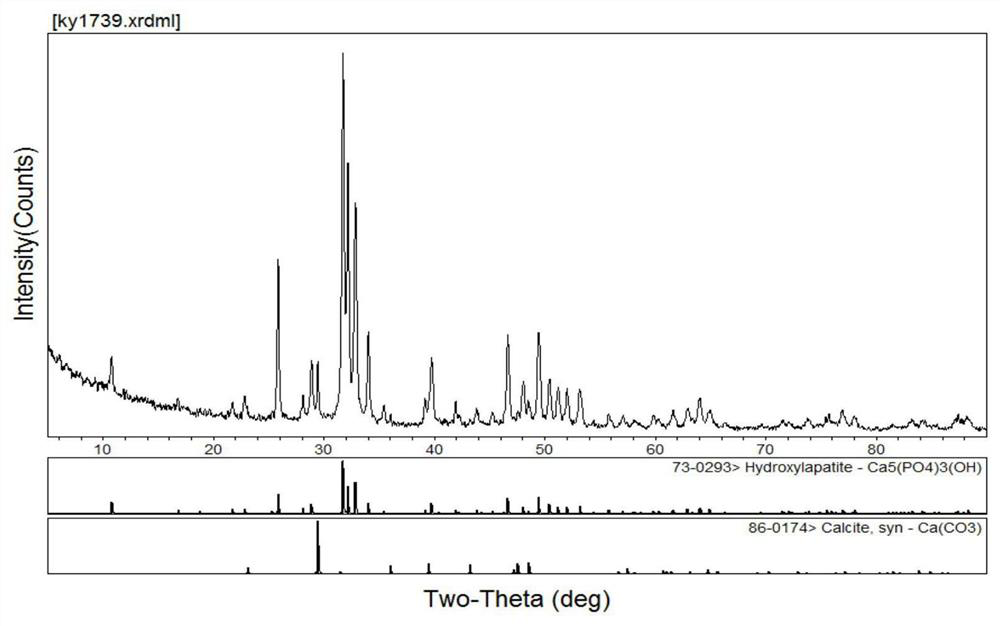

Embodiment 2

[0052]This embodiment provides a preparation and molding method of a hydroxyl-containing calcium phosphate material, including the following steps:

[0053](1) Using anhydrous calcium hydrogen phosphate CaHPO4With calcium hydroxide Ca(OH)2Mixed as raw material of mixed inorganic calcium salt, Na2HPO4Aqueous solution as a feed ingredient;

[0054]Among them, in the mixed inorganic calcium salt raw materials, anhydrous calcium hydrogen phosphate CaHPO4With calcium hydroxide Ca(OH)2The total Ca / P ratio is 1.6; CaHPO is processed by a gas micro-pulverizer4And Ca(OH)2, Make its average particle size D50 4-6μm.

[0055](2) Weigh 10g, 1M Na of the mixed inorganic calcium salt raw material in step (1)2HPO4Put 2.6mL of the solution in a porcelain dish and mix it, add 50g of water under normal temperature and pressure conditions, stir evenly to obtain a mixed slurry, flatten the mixed slurry naturally under vibration conditions, add a small amount of water to cover the surface of the slurry, and cover...

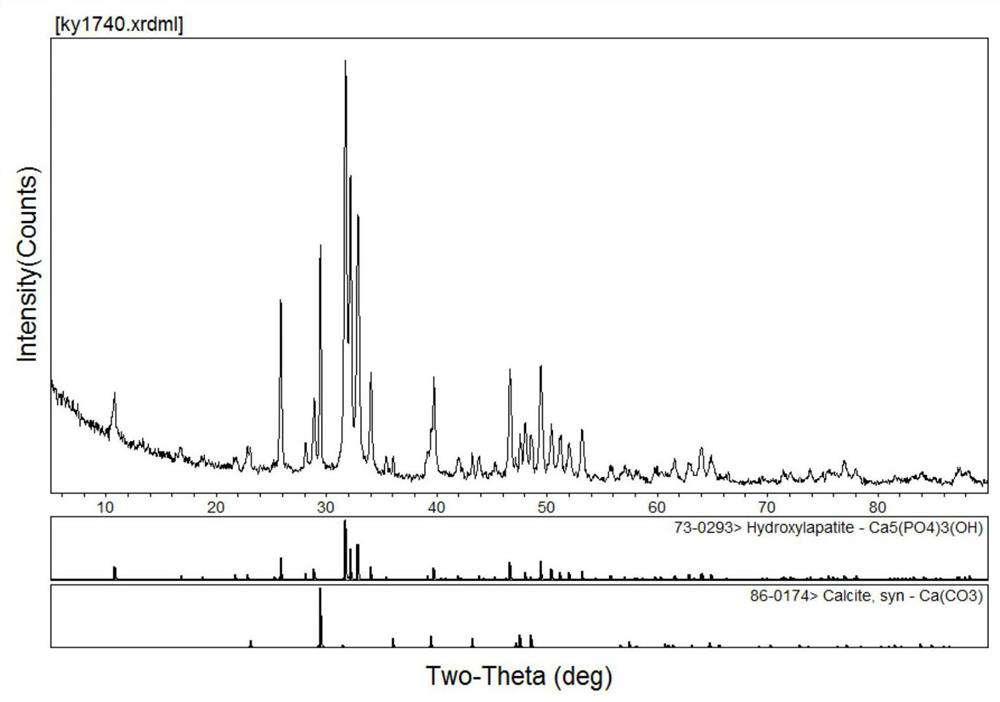

Embodiment 3

[0059]This embodiment provides a preparation and molding method of a hydroxyl-containing calcium phosphate material, including the following steps:

[0060](1) Using calcium hydrogen phosphate dihydrate CaHPO4·2H2O is mixed with calcium oxide CaO as the raw material of mixed inorganic calcium salt, (NH4)2HPO4The aqueous solution is used as a feed ingredient.

[0061]Among them, among the mixed inorganic calcium salt raw materials, calcium hydrogen phosphate dihydrate CaHPO4·2H2The total Ca / P ratio of O to calcium oxide CaO is 1.576. CaHPO4·2H2The average particle size D50 of O is 4-6μm, and the average particle size D50 of CaO is 5-8μm;

[0062](2) Weigh 10g of mixed inorganic calcium salt raw materials in step (1), 5M (NH4)2HPO4Place 2.6 mL of the solution in a porcelain dish and mix, add 50 g of water under normal temperature and pressure conditions, and stir evenly to obtain a mixed slurry. Spread the mixed slurry naturally under vibration conditions, add a small amount of water to cover ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com