Well completion process improvement method suitable for water-saturated thick silty-fine sand layer

A process improvement, silty sand technology, applied in the field of drilling in special strata and drilling pile construction technology, can solve problems such as affecting the water permeability of dewatering wells, unable to ensure foundation pit excavation, and waterless construction, etc. The effect of good well wall protection and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The following describes the technical solutions in the embodiments of the present invention clearly and completely with reference to the accompanying drawings in the embodiments of the present invention; it is obvious that the described embodiments are only a part of the embodiments of the present invention; not all the embodiments. Based on the embodiments of the present invention; all other embodiments obtained by those of ordinary skill in the art without creative work; all fall within the protection scope of the present invention.

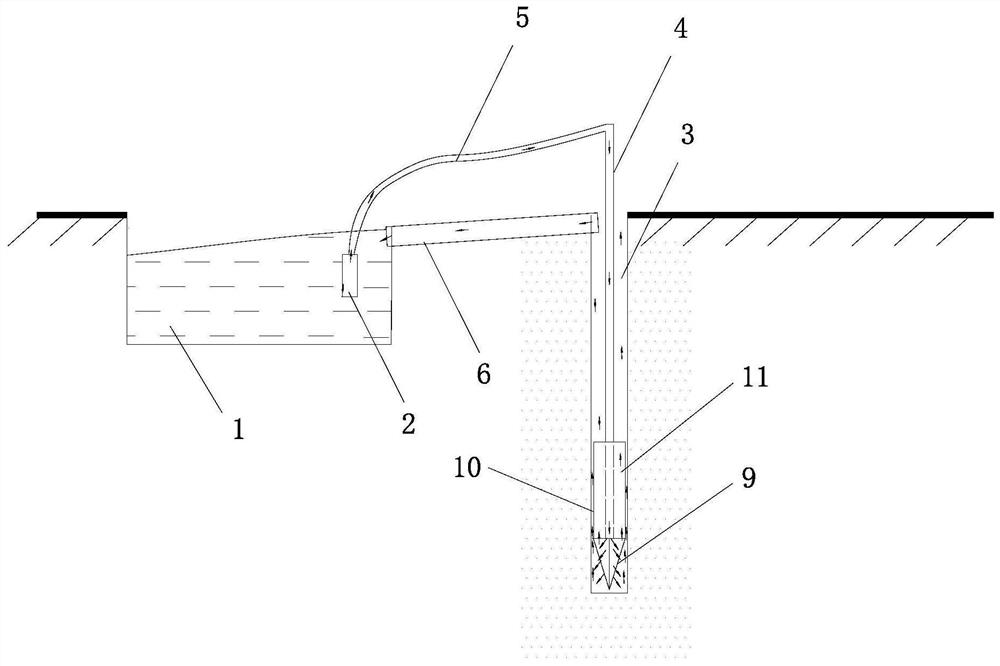

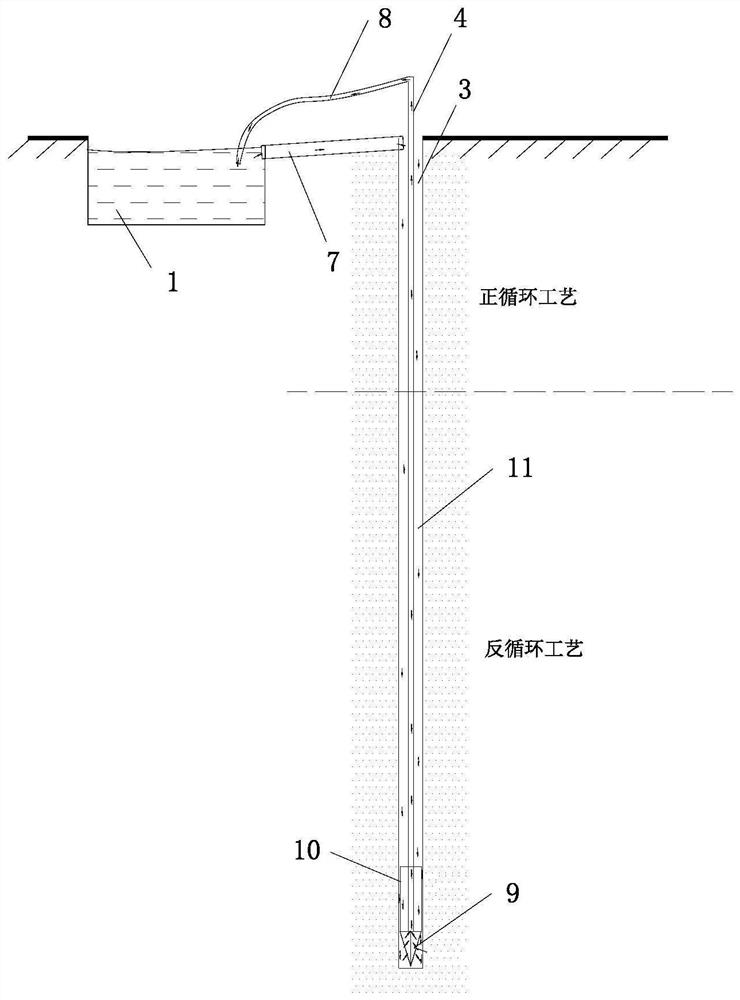

[0022]Such asfigure 1 ,figure 2As shown, the present invention discloses a method for improving the well formation process suitable for saturated thick silt fine sand layers. The well formation process of this special bottom layer is drilled, the bit structure of the circulating drill and the chemical wall mud are reconfigured. These improvements have solved the technical difficulties of traditional drilling technology in protecting the wall on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com