A kind of high-strength permeable concrete and preparation method thereof

A permeable concrete and high-strength technology, applied in the field of building materials, can solve the problems of low compressive strength and a large number of structural cracks in concrete, and achieve the effect of improving fracture toughness, high hardness, compressive strength and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

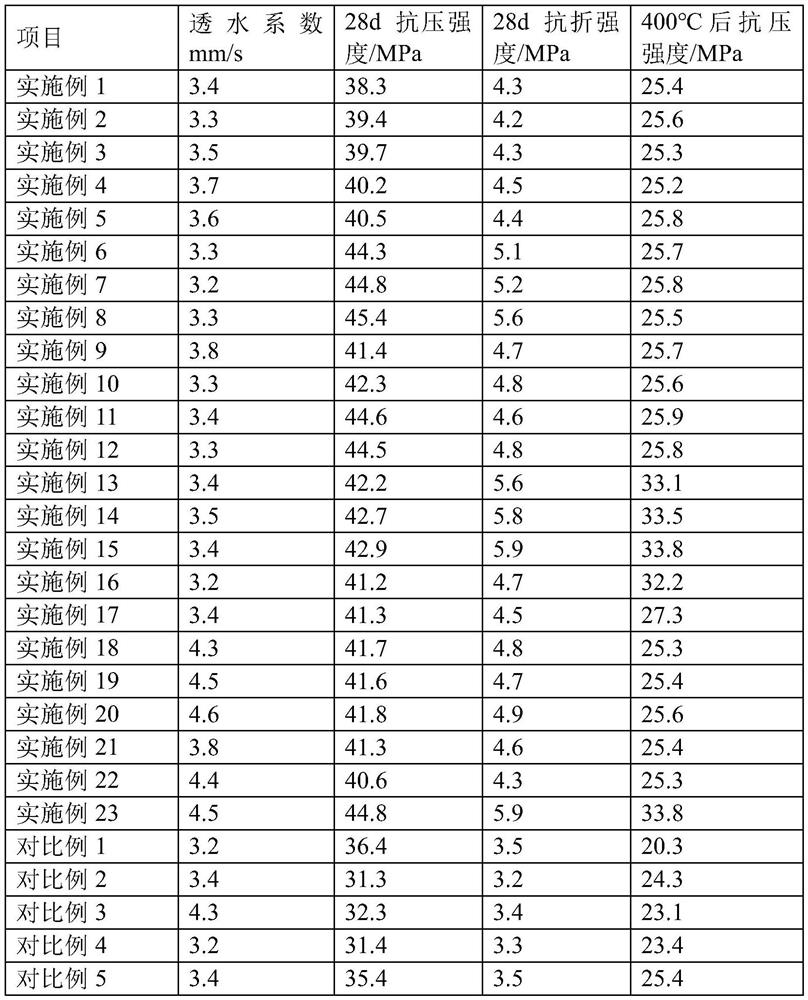

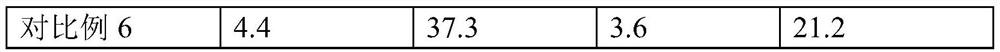

Examples

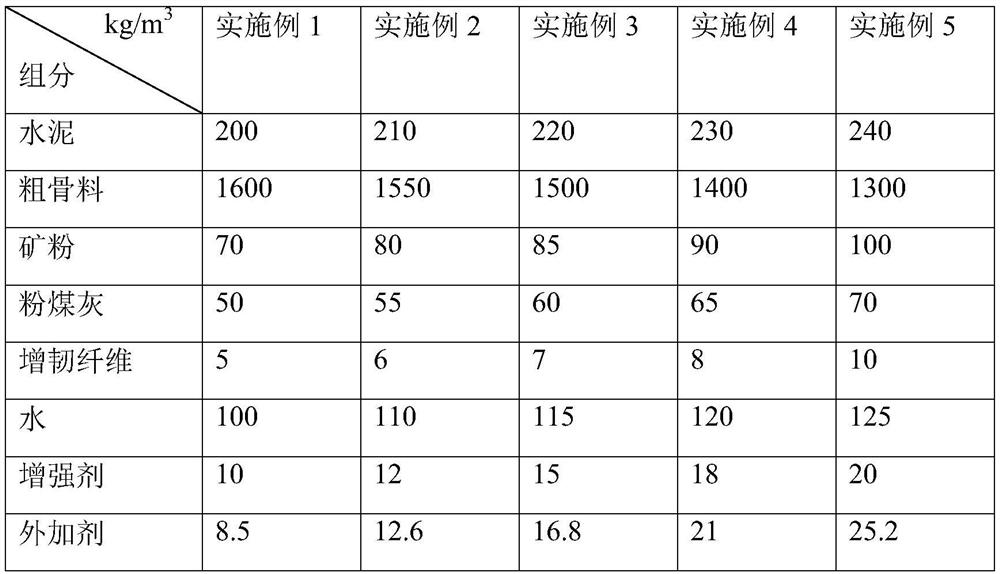

preparation example 1-5

[0045] Boron carbide in preparation example 1-5 was selected from Hebei Yangming Metal Material Co., Ltd., the model is NYT-B4C-1, and the average particle size is 60nm; Nano titanium dioxide is selected from Jiangsu Tianxing New Materials Co., Ltd., the stock number is A12; Graphite powder is selected from Guangdong Yongyao Graphite Technology Co., Ltd., model is YY-04; Alumina is selected from Zibo Yinhan Special Alumina Co., Ltd., model A318.

preparation example 1

[0046] Preparation Example 1: (1) 2kg of boron carbide and 1kg of nano titanium dioxide were dried at 110 °C for 24 h, then mixed with graphite powder, mixed at 50Pa, 1800 °C for 2h under an inert atmosphere, cooled to room temperature, the mass ratio of graphite powder to nano titanium dioxide was 3.5:1;

[0047] (2) Add 5kg of alumina to 10kg of deionized water, stir evenly, dry at 100 °C for 4h, then heat up to 200 °C / h at a heating rate of 200 °C / h, keep warm for 1h, then heat up to 700 °C at a rate of 175 °C / h, keep warm for 3h, cool down to room temperature, crush, pass through a 60 mesh sieve to obtain α- alumina spherical granules;

[0048](3) The proceeds of step (1) and the proceeds of step (2) are mixed evenly, grinded at a speed of 200r / min for 5h, kept warm at 1450 °C and 24MPa for 15min, cooled to room temperature, crushed, sieved, and prepared a reinforcing agent, and the mass ratio of the obtained substances and the obtained substances of step (1) and step (2) is 0...

preparation example 2

[0049] Preparation Example 2: (1) 2.3kg boron carbide and 1.15kg nano titanium dioxide are dried at 110 °C for 24h, then mixed with graphite powder, mixed at 60Pa, 1700 °C for 1h under an inert atmosphere, cooled to room temperature, the mass ratio of graphite powder to nano titanium dioxide is 4:1;

[0050] (2) Add 5.5kg of alumina to 11kg of deionized water, stir evenly, dry at 110 °C for 3.5h, then heat up to 220 °C / h at a heating rate of 220 °C, keep warm for 1h, and then heat up to 750 °C at a rate of 190 °C / h, keep warm for 3h, cool down to room temperature, crush, through a 60 mesh sieve to obtain α-alumina spherical particles;

[0051] (3) The proceeds of step (1) and the proceeds of step (2) are mixed evenly, grinded at a speed of 250r / min for 4.5h, kept warm for 13min at 1500 °C and 27MPa, cooled to room temperature, crushed, sieved, and prepared to enhance the agent, and the mass ratio of the obtained substances of step (1) and the obtained substances of step (2) is 0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com